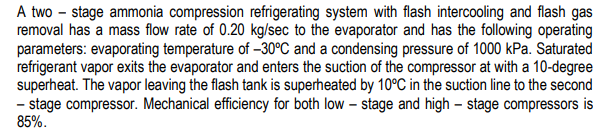

A two - stage ammonia compression refrigerating system with flash intercooling and flash gas removal has a mass flow rate of 0.20 kg/sec to the evaporator and has the following operating parameters: evaporating temperature of –30°C and a condensing pressure of 1000 kPa. Saturated refrigerant vapor exits the evaporator and enters the suction of the compressor at with a 10-degree superheat. The vapor leaving the flash tank is superheated by 10°C in the suction line to the second - stage compressor. Mechanical efficiency for both low – stage and high – stage compressors is

Theory and Design for Mechanical Measurements

Measurement is a term that refers to analyzing a manufactured component regarding the degree of accuracy for dimensions, tolerances, geometric profile, roundness, flatness, smoothness, etc. Measurement always involves comparing the manufactured component or the prototype with a standard specimen whose dimensions and other parameters are assumed to be perfect and do not undergo changes with respect to time.Precisely in mechanical engineering the branch that deals with the application of scientific principles for measurements is known as metrology. The domain of metrology in general deals with various measurements like mechanical, chemical, thermodynamic, physical, and biological measurements. In mechanical engineering, the measurements are limited to mechanical specific such as length, mass, surface profile, flatness, roundness, viscosity, heat transfer, etc.

Basic principles of engineering metrology

Metrology is described as the science of measurement, precision, and accuracy. In other words, it is a method of measurement based on units and predefined standards.

Instructions:

- Demonstrates thorough understanding of the problem and precisely identifies and collects all

significant data and requirements of the problem. - A realistic diagram/illustration of the physical system indicating relevant information in the figure.

- Assumptions and approximations are sufficiently and clearly stated.

- Selects an effective and efficient problem – solving strategy that will lead to a valid and accurate

solution to the problem. Relevant physical laws and principles were identified. Realistic constraints were

considered and well-defined before solutions are implemented. - Accurately implements the problem – solving strategy to achieve a valid and accurate solution. No

errors are present. - Provides concise and insightful justification to the solution using appropriate data.

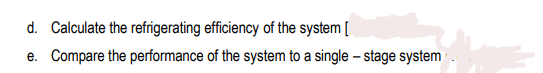

Step by step

Solved in 5 steps