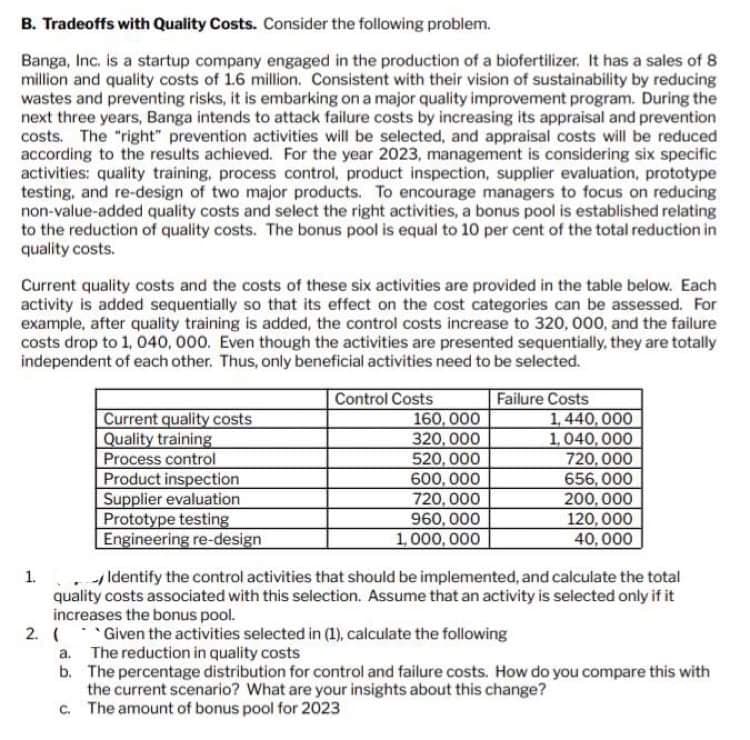

B. Tradeoffs with Quality Costs. Consider the following problem. Banga, Inc. is a startup company engaged in the production of a biofertilizer. It has a sales of 8 million and quality costs of 1.6 million. Consistent with their vision of sustainability by reducing wastes and preventing risks, it is embarking on a major quality improvement program. During the next three years, Banga intends to attack failure costs by increasing its appraisal and prevention costs. The "right" prevention activities will be selected, and appraisal costs will be reduced according to the results achieved. For the year 2023, management is considering six specific activities: quality training, process control, product inspection, supplier evaluation, prototype testing, and re-design of two major products. To encourage managers to focus on reducing non-value-added quality costs and select the right activities, a bonus pool is established relating to the reduction of quality costs. The bonus pool is equal to 10 per cent of the total reduction in quality costs. Current quality costs and the costs of these six activities are provided in the table below. Each activity is added sequentially so that its effect on the cost categories can be assessed. For example, after quality training is added, the control costs increase to 320, 000, and the failure costs drop to 1, 040, 000. Even though the activities are presented sequentially, they are totally independent of each other. Thus, only beneficial activities need to be selected. Control Costs 1. Current quality costs Quality training Process control Product inspection Supplier evaluation Prototype testing Engineering re-design 2. ( 160,000 320,000 520,000 600,000 720,000 960,000 1,000,000 a. The reduction in quality costs Failure Costs 1,440,000 1,040,000 Identify the control activities that should be implemented, and calculate the total quality costs associated with this selection. Assume that an activity is selected only if it increases the bonus pool. Given the activities selected in (1), calculate the following 720,000 656,000 200,000 120,000 40,000 b. The percentage distribution for control and failure costs. How do you compare this with the current scenario? What are your insights about this change? The amount of bonus pool for 2023 c.

B. Tradeoffs with Quality Costs. Consider the following problem. Banga, Inc. is a startup company engaged in the production of a biofertilizer. It has a sales of 8 million and quality costs of 1.6 million. Consistent with their vision of sustainability by reducing wastes and preventing risks, it is embarking on a major quality improvement program. During the next three years, Banga intends to attack failure costs by increasing its appraisal and prevention costs. The "right" prevention activities will be selected, and appraisal costs will be reduced according to the results achieved. For the year 2023, management is considering six specific activities: quality training, process control, product inspection, supplier evaluation, prototype testing, and re-design of two major products. To encourage managers to focus on reducing non-value-added quality costs and select the right activities, a bonus pool is established relating to the reduction of quality costs. The bonus pool is equal to 10 per cent of the total reduction in quality costs. Current quality costs and the costs of these six activities are provided in the table below. Each activity is added sequentially so that its effect on the cost categories can be assessed. For example, after quality training is added, the control costs increase to 320, 000, and the failure costs drop to 1, 040, 000. Even though the activities are presented sequentially, they are totally independent of each other. Thus, only beneficial activities need to be selected. Control Costs 1. Current quality costs Quality training Process control Product inspection Supplier evaluation Prototype testing Engineering re-design 2. ( 160,000 320,000 520,000 600,000 720,000 960,000 1,000,000 a. The reduction in quality costs Failure Costs 1,440,000 1,040,000 Identify the control activities that should be implemented, and calculate the total quality costs associated with this selection. Assume that an activity is selected only if it increases the bonus pool. Given the activities selected in (1), calculate the following 720,000 656,000 200,000 120,000 40,000 b. The percentage distribution for control and failure costs. How do you compare this with the current scenario? What are your insights about this change? The amount of bonus pool for 2023 c.

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Transcribed Image Text:B. Tradeoffs with Quality Costs. Consider the following problem.

Banga, Inc. is a startup company engaged in the production of a biofertilizer. It has a sales of 8

million and quality costs of 1.6 million. Consistent with their vision of sustainability by reducing

wastes and preventing risks, it is embarking on a major quality improvement program. During the

next three years, Banga intends to attack failure costs by increasing its appraisal and prevention

costs. The "right" prevention activities will be selected, and appraisal costs will be reduced

according to the results achieved. For the year 2023, management is considering six specific

activities: quality training, process control, product inspection, supplier evaluation, prototype

testing, and re-design of two major products. To encourage managers to focus on reducing

non-value-added quality costs and select the right activities, a bonus pool is established relating

to the reduction of quality costs. The bonus pool is equal to 10 per cent of the total reduction in

quality costs.

Current quality costs and the costs of these six activities are provided in the table below. Each

activity is added sequentially so that its effect on the cost categories can be assessed. For

example, after quality training is added, the control costs increase to 320, 000, and the failure

costs drop to 1, 040, 000. Even though the activities are presented sequentially, they are totally

independent of each other. Thus, only beneficial activities need to be selected.

1.

Current quality costs

Quality training

Process control

Product inspection

Supplier evaluation

Prototype testing

Engineering re-design

2. (

Control Costs

160,000

320,000

520,000

600,000

720,000

960,000

1,000,000

Failure Costs

1,440,000

1,040,000

- Identify the control activities that should be implemented, and calculate the total

quality costs associated with this selection. Assume that an activity is selected only if it

increases the bonus pool.

Given the activities selected in (1), calculate the following

720,000

656,000

200,000

120,000

40,000

a. The reduction in quality costs

b. The percentage distribution for control and failure costs. How do you compare this with

the current scenario? What are your insights about this change?

c. The amount of bonus pool for 2023

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.