Based of the attached case: *Competitive firms do not realize profits or incur losses in the long-run due to free entry and exit of new firms, based off the assumption that the prices of inputs (labor, capital, etc. remain unchanged) . Apply the case of the ethanol plants during 2006 and 2016 to demonstrate the above assertion. *Provide an extra example to the ethanol plants case used.

Based of the attached case: *Competitive firms do not realize profits or incur losses in the long-run due to free entry and exit of new firms, based off the assumption that the prices of inputs (labor, capital, etc. remain unchanged) . Apply the case of the ethanol plants during 2006 and 2016 to demonstrate the above assertion. *Provide an extra example to the ethanol plants case used.

Principles of Economics 2e

2nd Edition

ISBN:9781947172364

Author:Steven A. Greenlaw; David Shapiro

Publisher:Steven A. Greenlaw; David Shapiro

Chapter7: Production, Costs, And Industry Structure

Section: Chapter Questions

Problem 4SCQ: Based on your answers to the WipeOut Ski Company in Exercise 7.3, now imagine a situation where the...

Related questions

Question

Based of the attached case:

*Competitive firms do not realize

*Provide an extra example to the ethanol plants case used.

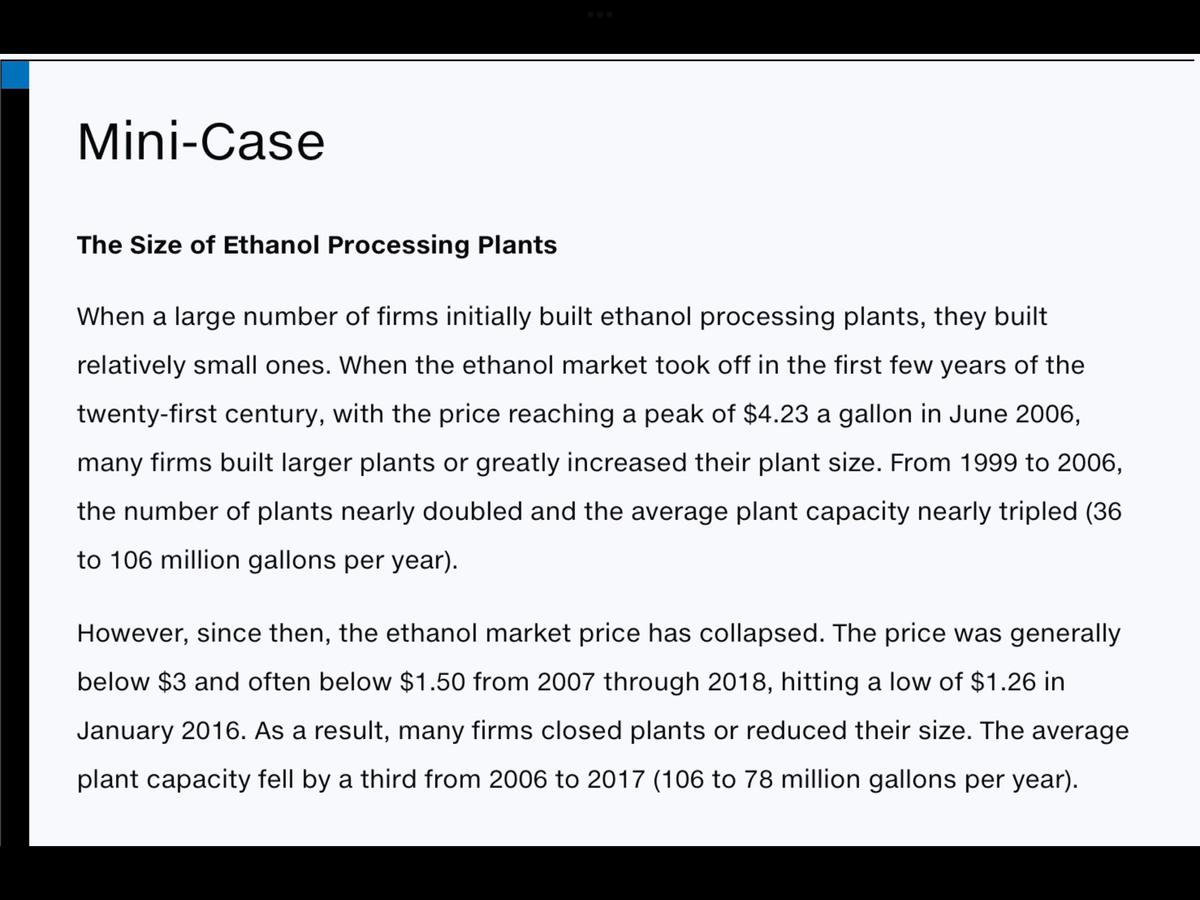

Transcribed Image Text:Mini-Case

The Size of Ethanol Processing Plants

When a large number of firms initially built ethanol processing plants, they built

relatively small ones. When the ethanol market took off in the first few years of the

twenty-first century, with the price reaching a peak of $4.23 a gallon in June 2006,

many firms built larger plants or greatly increased their plant size. From 1999 to 2006,

the number of plants nearly doubled and the average plant capacity nearly tripled (36

to 106 million gallons per year).

However, since then, the ethanol market price has collapsed. The price was generally

below $3 and often below $1.50 from 2007 through 2018, hitting a low of $1.26 in

January 2016. As a result, many firms closed plants or reduced their size. The average

plant capacity fell by a third from 2006 to 2017 (106 to 78 million gallons per year).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, economics and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Economics 2e

Economics

ISBN:

9781947172364

Author:

Steven A. Greenlaw; David Shapiro

Publisher:

OpenStax

Microeconomics: Principles & Policy

Economics

ISBN:

9781337794992

Author:

William J. Baumol, Alan S. Blinder, John L. Solow

Publisher:

Cengage Learning

Principles of Economics 2e

Economics

ISBN:

9781947172364

Author:

Steven A. Greenlaw; David Shapiro

Publisher:

OpenStax

Microeconomics: Principles & Policy

Economics

ISBN:

9781337794992

Author:

William J. Baumol, Alan S. Blinder, John L. Solow

Publisher:

Cengage Learning

Economics (MindTap Course List)

Economics

ISBN:

9781337617383

Author:

Roger A. Arnold

Publisher:

Cengage Learning