below? Scenario: A large, high volume warehouse-style discount grocery & retail operation

below? Scenario: A large, high volume warehouse-style discount grocery & retail operation

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter12: Queueing Models

Section12.5: Analytic Steady-state Queueing Models

Problem 30P

Related questions

Question

100%

A. 1.6 pallets per hour

B. 10 pallets per hour

C. 6 pallets per hour

D. 2 pallets per hour

E. Impossible to determine

Transcribed Image Text:Is the capacity or the system in the scenario below?

Scenario:

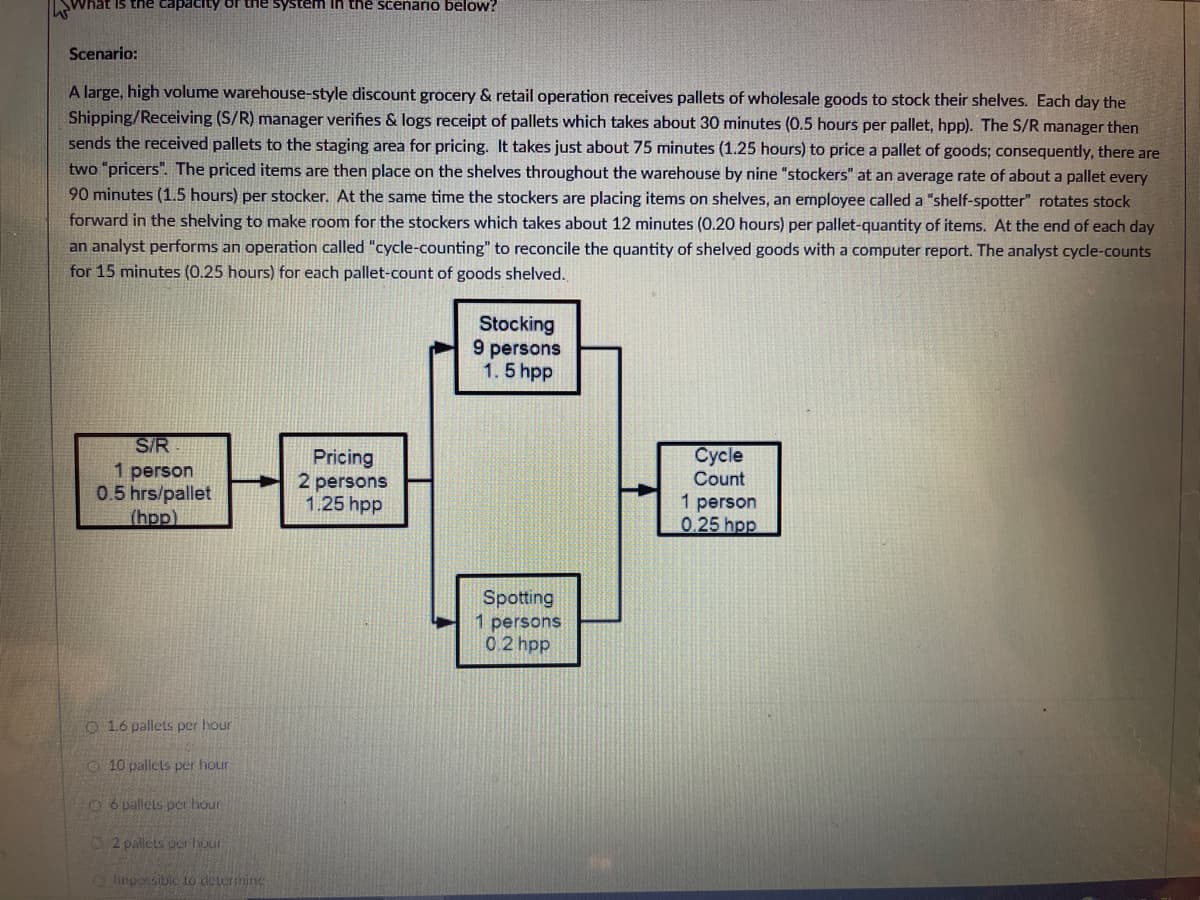

A large, high volume warehouse-style discount grocery & retail operation receives pallets of wholesale goods to stock their shelves. Each day the

Shipping/Receiving (S/R) manager verifies & logs receipt of pallets which takes about 30 minutes (0.5 hours per pallet, hpp). The S/R manager then

sends the received pallets to the staging area for pricing. It takes just about 75 minutes (1.25 hours) to price a pallet of goods; consequently, there are

two "pricers". The priced items are then place on the shelves throughout the warehouse by nine "stockers" at an average rate of about a pallet every

90 minutes (1.5 hours) per stocker. At the same time the stockers are placing items on shelves, an employee called a "shelf-spotter" rotates stock

forward in the shelving to make room for the stockers which takes about 12 minutes (0.20 hours) per pallet-quantity of items. At the end of each day

an analyst performs an operation called "cycle-counting" to reconcile the quantity of shelved goods with a computer report. The analyst cycle-counts

for 15 minutes (0.25 hours) for each pallet-count of goods shelved.

Stocking

9 persons

1.5 hpp

S/R

1 person

0.5 hrs/pallet

מh)

Pricing

2 persons

1.25 hpp

Сycle

Count

1 person

0.25 hpp

Spotting

1 persons

0.2 hpp

O 16 pallets per hour

O 10 pallets per hour

O 6 pallets per hour

O2 palets per huur

O limpossiblc to deterinine

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 5 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,