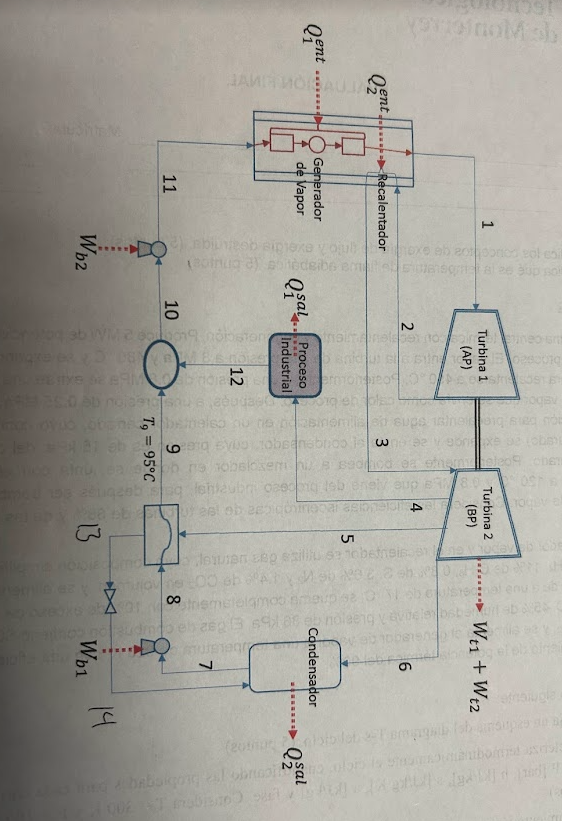

Consider a thermal power plant with reheating and cogeneration. It produces 5 MW of power and 4 MW of process heat. The steam enters the high-pressure turbine at 8 MPa and 480 °C and expands to 1.2 MPa, to be reheated to 450 C. Subsequently, at a pressure of 0.8 MPa, a fraction of 0.152 of steam is extracted, which is sent as process heat. Then, at a pressure of 0.25 MPa, another extraction is made to preheat feed water in a closed heater, whose condensate (saturated liquid) expands and is sent to the condenser, whose pressure is 15 kPa, from which saturated liquid comes out. Subsequently, it is pumped to a mixer where it joins with the subcooled liquid at 120 C and 0.8 MPa that comes from the industrial process, to be later pumped to the steam generator. Consider the isentropic efficiencies of the turbines of 88% and of the pumps of 82%. In the steam generator and in the superheater, natural gas is used, whose simplified composition is 83.2% CH4, 11% C2H6, 0.8% S, 3.6% N2 and 1.4% CO2 by volume, and is fed at a At a temperature of 17C, it burns completely with 10% excess air entering at 17C, 45% relative humidity, and 86 kPa pressure. The combustion gas contains SO2, CO2, H2O, O2 and N2, and is fed to the steam generator at a temperature of 923 K, with an efficiency of use of thermal power of 90%. Develop the following a) Thermodynamically characterize the cycle, quantifying the properties for each current: T [C], P [bar], h [kJ/kg], s [kJ/kg(K)], [kJ/kg) and phase. Consider T0= 300 K and Po= 100 ka

Consider a thermal power plant with reheating and cogeneration. It produces 5 MW of power and 4 MW of process heat. The steam enters the high-pressure turbine at 8 MPa and 480 °C and expands to 1.2 MPa, to be reheated to 450 C. Subsequently, at a pressure of 0.8 MPa, a fraction of 0.152 of steam is extracted, which is sent as process heat. Then, at a pressure of 0.25 MPa, another extraction is made to preheat feed water in a closed heater, whose condensate (saturated liquid) expands and is sent to the condenser, whose pressure is 15 kPa, from which saturated liquid comes out. Subsequently, it is pumped to a mixer where it joins with the subcooled liquid at 120 C and 0.8 MPa that comes from the industrial process, to be later pumped to the steam generator. Consider the isentropic efficiencies of the turbines of 88% and of the pumps of 82%. In the steam generator and in the superheater, natural gas is used, whose simplified composition is 83.2% CH4, 11% C2H6, 0.8% S, 3.6% N2 and 1.4% CO2 by volume, and is fed at a At a temperature of 17C, it burns completely with 10% excess air entering at 17C, 45% relative humidity, and 86 kPa pressure. The combustion gas contains SO2, CO2, H2O, O2 and N2, and is fed to the steam generator at a temperature of 923 K, with an efficiency of use of thermal power of 90%.

Develop the following

a)

Step by step

Solved in 2 steps with 8 images