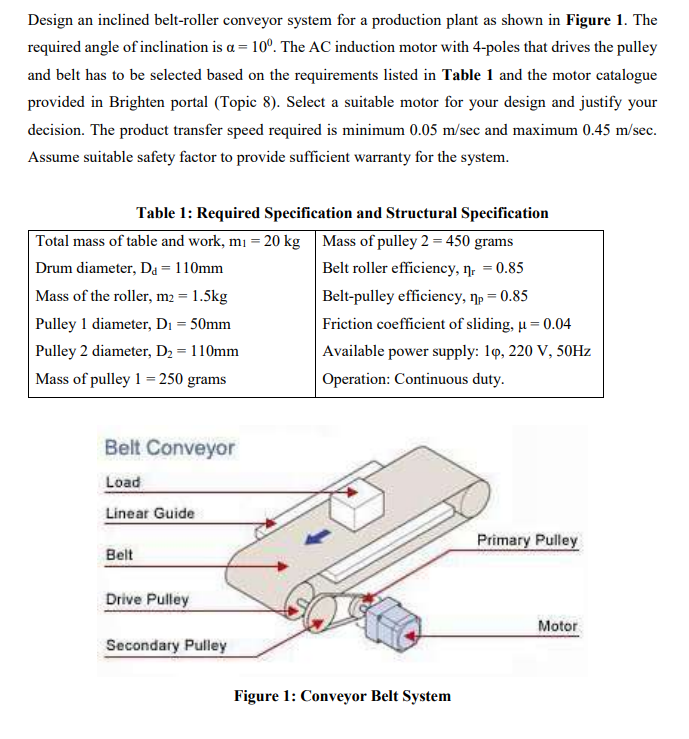

Design an inclined belt-roller conveyor system for a production plant as shown in Figure 1. The required angle of inclination is a = 10°. The AC induction motor with 4-poles that drives the pulley and belt has to be selected based on the requirements listed in Table 1 and the motor catalogue provided in Brighten portal (Topic 8). Select a suitable motor for your design and justify your decision. The product transfer speed required is minimum 0.05 m/sec and maximum 0.45 m/sec. Assume suitable safety factor to provide sufficient warranty for the system.

Design an inclined belt-roller conveyor system for a production plant as shown in Figure 1. The required angle of inclination is a = 10°. The AC induction motor with 4-poles that drives the pulley and belt has to be selected based on the requirements listed in Table 1 and the motor catalogue provided in Brighten portal (Topic 8). Select a suitable motor for your design and justify your decision. The product transfer speed required is minimum 0.05 m/sec and maximum 0.45 m/sec. Assume suitable safety factor to provide sufficient warranty for the system.

Automotive Technology: A Systems Approach (MindTap Course List)

6th Edition

ISBN:9781133612315

Author:Jack Erjavec, Rob Thompson

Publisher:Jack Erjavec, Rob Thompson

Chapter44: Four- And All-wheel Drive

Section: Chapter Questions

Problem 5RQ: What is the primary purpose of a transfer case?

Related questions

Question

Transcribed Image Text:Design an inclined belt-roller conveyor system for a production plant as shown in Figure 1. The

required angle of inclination is a = 10°. The AC induction motor with 4-poles that drives the pulley

and belt has to be selected based on the requirements listed in Table 1 and the motor catalogue

provided in Brighten portal (Topic 8). Select a suitable motor for your design and justify your

decision. The product transfer speed required is minimum 0.05 m/sec and maximum 0.45 m/sec.

Assume suitable safety factor to provide sufficient warranty for the system.

Table 1: Required Specification and Structural Specification

Total mass of table and work, m₁ = 20 kg Mass of pulley 2 = 450 grams

Drum diameter, Da = 110mm

Belt roller efficiency, r = 0.85

Mass of the roller, m2 = 1.5kg

Belt-pulley efficiency, ¹p = 0.85

Pulley 1 diameter, D₁ = 50mm

Friction coefficient of sliding, μ = 0.04

Pulley 2 diameter, D₂ = 110mm

Available power supply: 19, 220 V, 50Hz

Mass of pulley 1 = 250 grams

Operation: Continuous duty.

Belt Conveyor

Load

Linear Guide

Belt

Drive Pulley

Secondary Pulley

Figure 1: Conveyor Belt System

Primary Pulley

Motor

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Automotive Technology: A Systems Approach (MindTa…

Mechanical Engineering

ISBN:

9781133612315

Author:

Jack Erjavec, Rob Thompson

Publisher:

Cengage Learning

Automotive Technology: A Systems Approach (MindTa…

Mechanical Engineering

ISBN:

9781133612315

Author:

Jack Erjavec, Rob Thompson

Publisher:

Cengage Learning