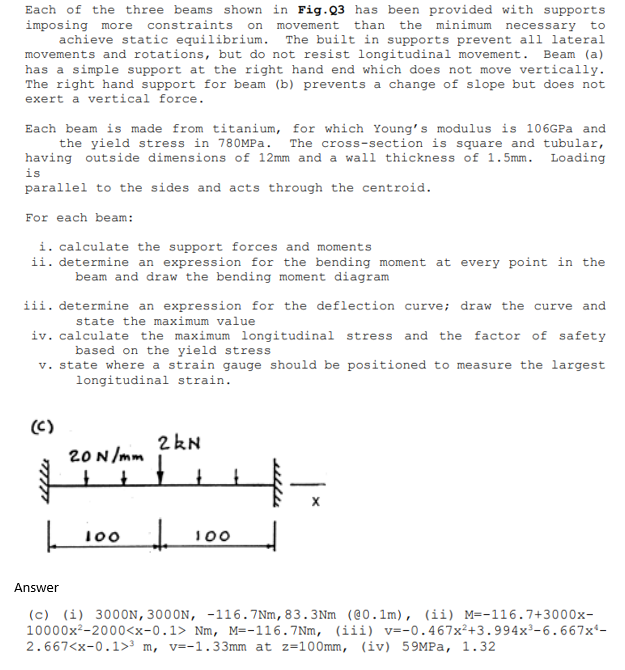

Each of the three beams shown in Fig. Q3 has been provided with supports imposing more constraints on movement than the minimum necessary to achieve static equilibrium. The built in supports prevent all lateral movements and rotations, but do not resist longitudinal movement. Beam (a) has a simple support at the right hand end which does not move vertically. The right hand support for beam (b) prevents a change of slope but does not exert a vertical force. Each beam is made from titanium, for which Young's modulus is 106GPa and the yield stress in 780MPa. The cross-section is square and tubular, having outside dimensions of 12mm and a wall thickness of 1.5mm. Loading is parallel to the sides and acts through the centroid. For each beam: i. calculate the support forces and moments ii. determine an expression for the bending moment at every point in the beam and draw the bending moment diagram iii. determine an expression for the deflection curve; draw the curve and state the maximum value iv. calculate the maximum longitudinal stress and the factor of safety based on the yield stress v. state where a strain gauge should be positioned to measure the largest longitudinal strain. (C) 20 N/mm + L 100 2 kN ↓ it 100

Each of the three beams shown in Fig. Q3 has been provided with supports imposing more constraints on movement than the minimum necessary to achieve static equilibrium. The built in supports prevent all lateral movements and rotations, but do not resist longitudinal movement. Beam (a) has a simple support at the right hand end which does not move vertically. The right hand support for beam (b) prevents a change of slope but does not exert a vertical force. Each beam is made from titanium, for which Young's modulus is 106GPa and the yield stress in 780MPa. The cross-section is square and tubular, having outside dimensions of 12mm and a wall thickness of 1.5mm. Loading is parallel to the sides and acts through the centroid. For each beam: i. calculate the support forces and moments ii. determine an expression for the bending moment at every point in the beam and draw the bending moment diagram iii. determine an expression for the deflection curve; draw the curve and state the maximum value iv. calculate the maximum longitudinal stress and the factor of safety based on the yield stress v. state where a strain gauge should be positioned to measure the largest longitudinal strain. (C) 20 N/mm + L 100 2 kN ↓ it 100

Chapter9: Application Of Influence Lines

Section: Chapter Questions

Problem 11P

Related questions

Question

Transcribed Image Text:Each of the three beams shown in Fig.Q3 has been provided with supports

imposing more constraints on movement than the minimum necessary to

achieve static equilibrium. The built in supports prevent all lateral

movements and rotations, but do not resist longitudinal movement. Beam (a)

has a simple support at the right hand end which does not move vertically.

The right hand support for beam (b) prevents a change of slope but does not

exert a vertical force.

Each beam is made from titanium, for which Young's modulus is 106GPa and

the yield stress in 780MPa. The cross-section is square and tubular,

having outside dimensions of 12mm and a wall thickness of 1.5mm. Loading.

is

parallel to the sides and acts through the centroid.

For each beam:

i. calculate the support forces and moments

ii. determine an expression for the bending moment at every point in the

beam and draw the bending moment diagram

iii. determine an expression for the deflection curve; draw the curve and

state the maximum value

iv. calculate the maximum longitudinal stress and the factor of safety

based on the yield stress

v. state where a strain gauge should be positioned to measure the largest

longitudinal strain.

(C)

T

20 N/mm

2kN

+

L 100 ite 100

Answer

(c) (i) 3000N, 3000N, -116.7Nm, 83.3Nm (@0.1m), (ii) M=-116.7+3000x-

10000x²-2000<x-0.1> Nm, M=-116.7Nm, (iii) v=-0.467x²+3.994x³-6.667x¹-

2.667<x-0.1>³ m, v=-1.33mm at z=100mm, (iv) 59MPa, 1.32

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you