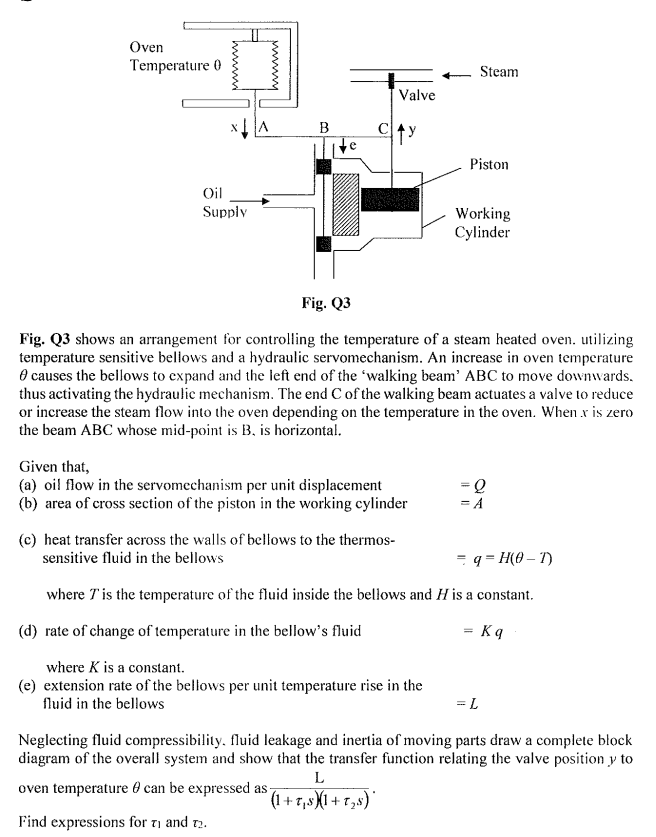

Fig. Q3 shows an arrangement for controlling the temperature of a steam heated oven. utilizing temperature sensitive bellows and a hydraulic servomechanism. An increase in oven temperature causes the bellows to expand and the left end of the 'walking beam' ABC to move downwards. thus activating the hydraulic mechanism. The end C of the walking beam actuates a valve to reduce or increase the steam flow into the oven depending on the temperature in the oven. When .x is zero the beam ABC whose mid-point is B. is horizontal. Given that, (a) oil flow in the servomechanism per unit displacement (b) area of cross section of the piston in the working cylinder -Q - A (c) heat transfer across the walls of bellows to the thermos- sensitive fluid in the bellows q=H(0-7) where I' is the temperature of the fluid inside the bellows and H is a constant. (d) rate of change of temperature in the bellow's fluid Kq where K is a constant. (e) extension rate of the bellows per unit temperature rise in the fluid in the bellows FL Neglecting fluid compressibility, fluid leakage and inertia of moving parts draw a complete block diagram of the overall system and show that the transfer function relating the valve position y to L oven temperature can be expressed as (1+7₁8)(1+7₂8) Find expressions for 7₁ and 72.

Fig. Q3 shows an arrangement for controlling the temperature of a steam heated oven. utilizing temperature sensitive bellows and a hydraulic servomechanism. An increase in oven temperature causes the bellows to expand and the left end of the 'walking beam' ABC to move downwards. thus activating the hydraulic mechanism. The end C of the walking beam actuates a valve to reduce or increase the steam flow into the oven depending on the temperature in the oven. When .x is zero the beam ABC whose mid-point is B. is horizontal. Given that, (a) oil flow in the servomechanism per unit displacement (b) area of cross section of the piston in the working cylinder -Q - A (c) heat transfer across the walls of bellows to the thermos- sensitive fluid in the bellows q=H(0-7) where I' is the temperature of the fluid inside the bellows and H is a constant. (d) rate of change of temperature in the bellow's fluid Kq where K is a constant. (e) extension rate of the bellows per unit temperature rise in the fluid in the bellows FL Neglecting fluid compressibility, fluid leakage and inertia of moving parts draw a complete block diagram of the overall system and show that the transfer function relating the valve position y to L oven temperature can be expressed as (1+7₁8)(1+7₂8) Find expressions for 7₁ and 72.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter6: Forced Convection Over Exterior Surfaces

Section: Chapter Questions

Problem 6.2DP

Related questions

Question

Transcribed Image Text:Oven

Temperature 0

wwwwww

Valve

↑y

Steam

B

Piston

Oil

Supply

H

Working

Cylinder

Fig. Q3

Fig. Q3 shows an arrangement for controlling the temperature of a steam heated oven. utilizing

temperature sensitive bellows and a hydraulic servomechanism. An increase in oven temperature

causes the bellows to expand and the left end of the 'walking beam' ABC to move downwards.

thus activating the hydraulic mechanism. The end C of the walking beam actuates a valve to reduce

or increase the steam flow into the oven depending on the temperature in the oven. When .x is zero

the beam ABC whose mid-point is B, is horizontal.

Given that,

(a) oil flow in the servomechanism per unit displacement

(b) area of cross section of the piston in the working cylinder

-Q

= A

(c) heat transfer across the walls of bellows to the thermos-

sensitive fluid in the bellows

=q=H(0-1)

where I' is the temperature of the fluid inside the bellows and H is a constant.

(d) rate of change of temperature in the bellow's fluid

Kq

where K is a constant.

(e) extension rate of the bellows per unit temperature rise in the

fluid in the bellows

= L

Neglecting fluid compressibility, fluid leakage and inertia of moving parts draw a complete block

diagram of the overall system and show that the transfer function relating the valve position y to

L

oven temperature can be expressed as-

(1+7₁8)(1+T₂s)

Find expressions for 71 and 72.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning