Grinding wheels wear like conventional cutting tools. Three wear mechanisms are known as the main causes of wear in grinding whee 1) Grain break 2) frictional wear 3)... Which of the following words best complements the space given above? Taşlama tasları konvanci 1, Tane kırılması 35 - -vI NGSICI iakimiar giDi aşilai. Uy ag vnim ima taslarında aşınmanın ana sebepleri olara

Grinding wheels wear like conventional cutting tools. Three wear mechanisms are known as the main causes of wear in grinding whee 1) Grain break 2) frictional wear 3)... Which of the following words best complements the space given above? Taşlama tasları konvanci 1, Tane kırılması 35 - -vI NGSICI iakimiar giDi aşilai. Uy ag vnim ima taslarında aşınmanın ana sebepleri olara

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter7: Grinding

Section7.3: Surface Grinding Operations

Problem 8RQ: Depth-of-cut range for surface grinding is: a. 0.010"0.100" b. 0.0001"0.0002" c. 0.0001"0.003" d....

Related questions

Question

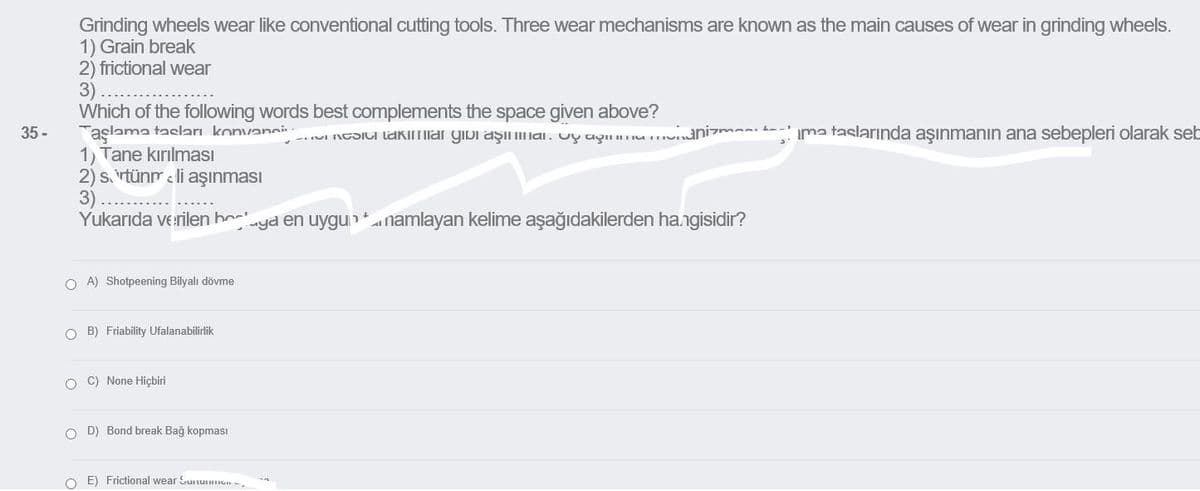

Transcribed Image Text:Grinding wheels wear like conventional cutting tools. Three wear mechanisms are known as the main causes of wear in grinding wheels.

1) Grain break

2) frictional wear

3)

Which of the following words best complements the space given above?

Taşlama tasları konvanci

1) Tane kırılması

2) s. rtünr e li aşınması

3)

Yukarıda verilen ho

35 -

-.UI NCSICI lakimiar gibi aşilai. vy ayinHun

anizma t-

ima taslarında aşınmanın ana sebepleri olarak seb

yd en uygu namlayan kelime aşağıdakilerden hangisidir?

O A) Shotpeening Bilyalı dövme

O B) Friability Ufalanabilirlik

O C) None Hiçbiri

O D) Bond break Bağ kopmasI

O E) Frictional wear Sutuon

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning