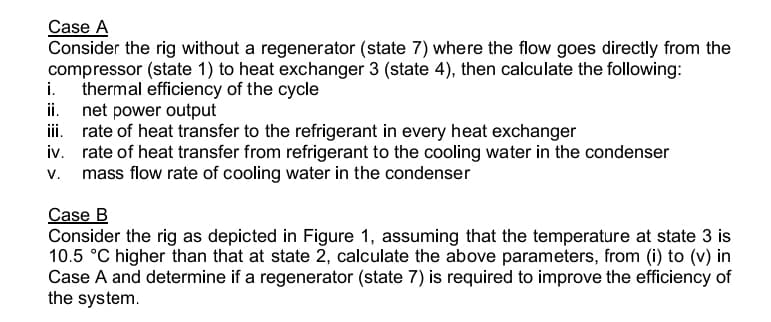

Group 29 Introduction Waste Heat Recovery (WHR) is a process to transform waste heat into useful work. This can be applied to various industrial processes, which produce waste heat over a wide range of temperatures [1]. In internal combustion engines, only 30-35% of the energy provided by fuel is converted to mechanical power, with the remaining two thirds of the fuel energy lost to the environment as heat via the coolant and exhaust gas [1]. Amongst different thermodynamic cycles, Organic Rankine Cycle (ORC) is considered as a viable technology for the WHR system. The ORC is the same as other conventional cycle energy systems (e.g. steam) but uses organic fluids such as refrigerants (e.g. R134a). Compared to the subcritical operating condition, the ORC system wringing under supercritical conditions has potential to improve the cycle thermal efficiencies up to 10-15%. Furthermore, the ORCS can be used in both mobile (e.g. trucks) and stationary applications (combined heat and power plants). ORC-WHR Figure 1 depicts an ORC-WHR system with multiple heat sources for stationary applications. The system has the capability of working in both subcritical and supercritical conditions. Liquid refrigerant at high pressure (state 3) goes through the three heat exchangers (state 4, 5 and 6). These heat exchanges are connected to three heat sources, which represent different (low, medium and high) grades waste heat available in industry. After the high-heat exchanger (state 6), the vapour refrigerant at high temperature and high pressure enters a turbine, which is connected to a generator and produces electricity. The refrigerant then goes into a regenerator (state 7). Here, the vapour refrigerant gives the remaining energy (which could not be extracted by the turbine) to the cold liquid refrigerant, which leaves the compressor (in process 2-3). A low temperature vapour then leaves the regenerator at state 8 and goes into a condenser, where it will be converted to liquid. Finally, the condensed liquid enters the compressor at state 1 and the cycle repeats. Heat source 3 Heat exchanger 3 Compressor Heat source 2 Heat exchanger 2 Organic Rankine Cycle Condenser Pranarod hy Yinwei Cheng Tturbine, inlet Pheat exchanger (°C) (bar) 180 30 8 2 Heat source 1 Heat exchanger 1 Regenerator 3 65 O Cooling water Figure 1 An ORC-WHR with multiple heat sources [1]. Turbine P condenser ncompressor nturbine mrefrig (%) (%) (kg/s) (bar) 5 0.4 82 G Generator Tw.cond.in (°C) 12.5 Tw.cond,out (°C) 25

Group 29 Introduction Waste Heat Recovery (WHR) is a process to transform waste heat into useful work. This can be applied to various industrial processes, which produce waste heat over a wide range of temperatures [1]. In internal combustion engines, only 30-35% of the energy provided by fuel is converted to mechanical power, with the remaining two thirds of the fuel energy lost to the environment as heat via the coolant and exhaust gas [1]. Amongst different thermodynamic cycles, Organic Rankine Cycle (ORC) is considered as a viable technology for the WHR system. The ORC is the same as other conventional cycle energy systems (e.g. steam) but uses organic fluids such as refrigerants (e.g. R134a). Compared to the subcritical operating condition, the ORC system wringing under supercritical conditions has potential to improve the cycle thermal efficiencies up to 10-15%. Furthermore, the ORCS can be used in both mobile (e.g. trucks) and stationary applications (combined heat and power plants). ORC-WHR Figure 1 depicts an ORC-WHR system with multiple heat sources for stationary applications. The system has the capability of working in both subcritical and supercritical conditions. Liquid refrigerant at high pressure (state 3) goes through the three heat exchangers (state 4, 5 and 6). These heat exchanges are connected to three heat sources, which represent different (low, medium and high) grades waste heat available in industry. After the high-heat exchanger (state 6), the vapour refrigerant at high temperature and high pressure enters a turbine, which is connected to a generator and produces electricity. The refrigerant then goes into a regenerator (state 7). Here, the vapour refrigerant gives the remaining energy (which could not be extracted by the turbine) to the cold liquid refrigerant, which leaves the compressor (in process 2-3). A low temperature vapour then leaves the regenerator at state 8 and goes into a condenser, where it will be converted to liquid. Finally, the condensed liquid enters the compressor at state 1 and the cycle repeats. Heat source 3 Heat exchanger 3 Compressor Heat source 2 Heat exchanger 2 Organic Rankine Cycle Condenser Pranarod hy Yinwei Cheng Tturbine, inlet Pheat exchanger (°C) (bar) 180 30 8 2 Heat source 1 Heat exchanger 1 Regenerator 3 65 O Cooling water Figure 1 An ORC-WHR with multiple heat sources [1]. Turbine P condenser ncompressor nturbine mrefrig (%) (%) (kg/s) (bar) 5 0.4 82 G Generator Tw.cond.in (°C) 12.5 Tw.cond,out (°C) 25

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter5: Analysis Of Convection Heat Transfer

Section: Chapter Questions

Problem 5.54P

Related questions

Question

100%

![Group

29

Introduction

Waste Heat Recovery (WHR) is a process to transform waste heat into useful work. This can

be applied to various industrial processes, which produce waste heat over a wide range of

temperatures [1]. In internal combustion engines, only 30-35% of the energy provided by fuel

is converted to mechanical power, with the remaining two thirds of the fuel energy lost to the

environment as heat via the coolant and exhaust gas [1]. Amongst different thermodynamic

cycles, Organic Rankine Cycle (ORC) is considered as a viable technology for the WHR

system. The ORC is the same as other conventional cycle energy systems (e.g. steam) but

uses organic fluids such as refrigerants (e.g. R134a). Compared to the subcritical operating

condition, the ORC system wringing under supercritical conditions has potential to improve

the cycle thermal efficiencies up to 10-15%. Furthermore, the ORCS can be used in both

mobile (e.g. trucks) and stationary applications (combined heat and power plants).

ORC-WHR

Figure 1 depicts an ORC-WHR system with multiple heat sources for stationary applications.

The system has the capability of working in both subcritical and supercritical conditions. Liquid

refrigerant at high pressure (state 3) goes through the three heat exchangers (state 4, 5 and

6). These heat exchanges are connected to three heat sources, which represent different (low,

medium and high) grades waste heat available in industry. After the high-heat exchanger

(state 6), the vapour refrigerant at high temperature and high pressure enters a turbine, which

is connected to a generator and produces electricity. The refrigerant then goes into a

regenerator (state 7). Here, the vapour refrigerant gives the remaining energy (which could

not be extracted by the turbine) to the cold liquid refrigerant, which leaves the compressor (in

process 2-3). A low temperature vapour then leaves the regenerator at state 8 and goes into

a condenser, where it will be converted to liquid. Finally, the condensed liquid enters the

compressor at state 1 and the cycle repeats.

(1)

Heat source 3

Heat

exchanger 3

Compressor

14

Pronarod hy Yinwei Cheng

Heat source 2

Condenser

Heat

exchanger 2 5

Organic Rankine Cycle

Tturbine,inlet Pheat exchanger

(°C)

(bar)

180

30

Cooling water

8

2

Heat source 1

Heat

exchanger 1

Regenerator

Figure 1 An ORC-WHR with multiple heat sources [1].

Turbine

P condenser ncompressor nturbine

(%)

(%)

(bar)

5

65

82

G

Generator

mrefrig. Tw.cond.in

(kg/s)

(°C)

0.4

12.5

Tw.cond,out

(°C)

25](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2F0280cc21-8041-4b35-83af-094302e775e5%2F6634047c-35dd-4bce-9916-4f326ffc1dd1%2F6lu8x0d_processed.jpeg&w=3840&q=75)

Transcribed Image Text:Group

29

Introduction

Waste Heat Recovery (WHR) is a process to transform waste heat into useful work. This can

be applied to various industrial processes, which produce waste heat over a wide range of

temperatures [1]. In internal combustion engines, only 30-35% of the energy provided by fuel

is converted to mechanical power, with the remaining two thirds of the fuel energy lost to the

environment as heat via the coolant and exhaust gas [1]. Amongst different thermodynamic

cycles, Organic Rankine Cycle (ORC) is considered as a viable technology for the WHR

system. The ORC is the same as other conventional cycle energy systems (e.g. steam) but

uses organic fluids such as refrigerants (e.g. R134a). Compared to the subcritical operating

condition, the ORC system wringing under supercritical conditions has potential to improve

the cycle thermal efficiencies up to 10-15%. Furthermore, the ORCS can be used in both

mobile (e.g. trucks) and stationary applications (combined heat and power plants).

ORC-WHR

Figure 1 depicts an ORC-WHR system with multiple heat sources for stationary applications.

The system has the capability of working in both subcritical and supercritical conditions. Liquid

refrigerant at high pressure (state 3) goes through the three heat exchangers (state 4, 5 and

6). These heat exchanges are connected to three heat sources, which represent different (low,

medium and high) grades waste heat available in industry. After the high-heat exchanger

(state 6), the vapour refrigerant at high temperature and high pressure enters a turbine, which

is connected to a generator and produces electricity. The refrigerant then goes into a

regenerator (state 7). Here, the vapour refrigerant gives the remaining energy (which could

not be extracted by the turbine) to the cold liquid refrigerant, which leaves the compressor (in

process 2-3). A low temperature vapour then leaves the regenerator at state 8 and goes into

a condenser, where it will be converted to liquid. Finally, the condensed liquid enters the

compressor at state 1 and the cycle repeats.

(1)

Heat source 3

Heat

exchanger 3

Compressor

14

Pronarod hy Yinwei Cheng

Heat source 2

Condenser

Heat

exchanger 2 5

Organic Rankine Cycle

Tturbine,inlet Pheat exchanger

(°C)

(bar)

180

30

Cooling water

8

2

Heat source 1

Heat

exchanger 1

Regenerator

Figure 1 An ORC-WHR with multiple heat sources [1].

Turbine

P condenser ncompressor nturbine

(%)

(%)

(bar)

5

65

82

G

Generator

mrefrig. Tw.cond.in

(kg/s)

(°C)

0.4

12.5

Tw.cond,out

(°C)

25

Transcribed Image Text:Case A

Consider the rig without a regenerator (state 7) where the flow goes directly from the

compressor (state 1) to heat exchanger 3 (state 4), then calculate the following:

i. thermal efficiency of the cycle

ii.

net power output

iii.

rate of heat transfer to the refrigerant in every heat exchanger

iv.

rate of heat transfer from refrigerant to the cooling water in the condenser

v. mass flow rate of cooling water in the condenser

Case B

Consider the rig as depicted in Figure 1, assuming that the temperature at state 3 is

10.5 °C higher than that at state 2, calculate the above parameters, from (i) to (v) in

Case A and determine if a regenerator (state 7) is required to improve the efficiency of

the system.

Expert Solution

Step by step

Solved in 9 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning