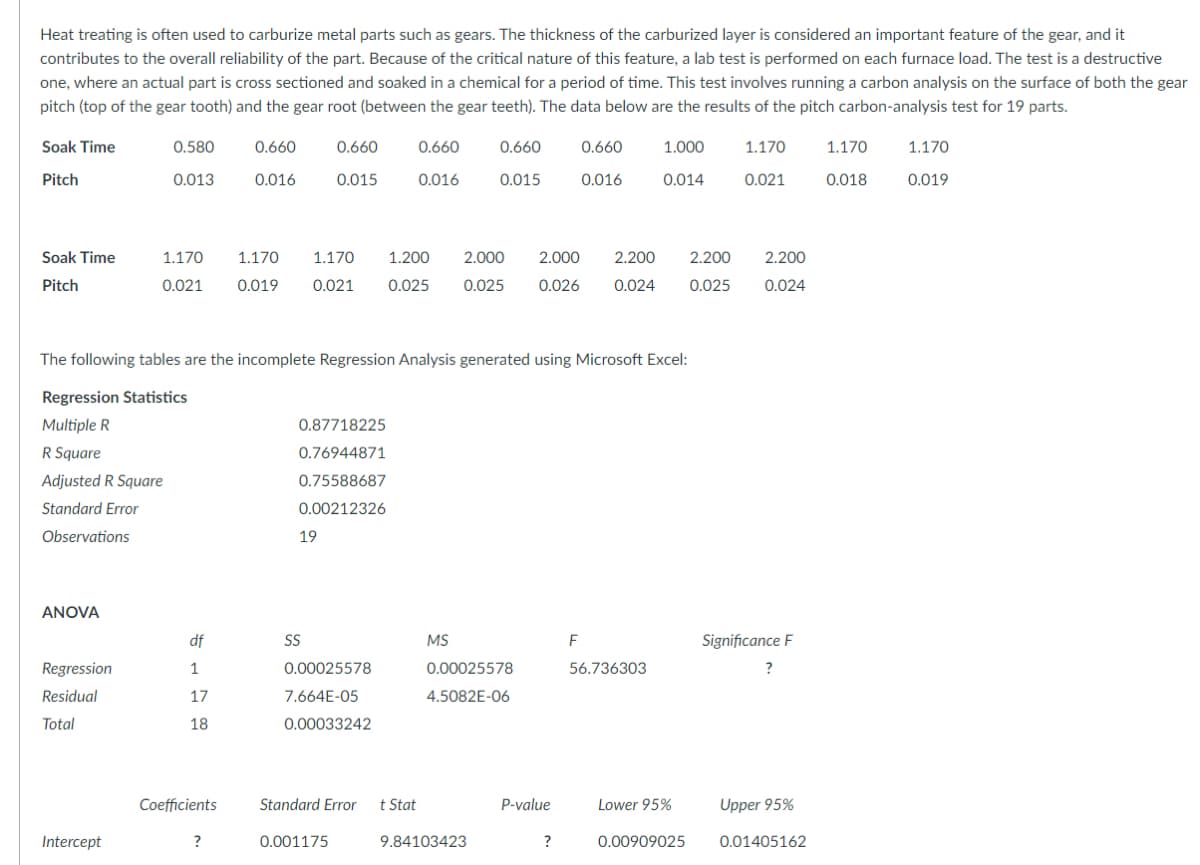

Heat treating is often used to carburize metal parts such as gears. The thickness of the carburized layer is considered an important feature of the gear, and it contributes to the overall reliability of the part. Because of the critical nature of this feature, a lab test is performed on each furnace load. The test is a destructive one, where an actual part is cross sectioned and soaked in a chemical for a period of time. This test involves running a carbon analysis on the surface of both the gear pitch (top of the gear tooth) and the gear root (between the gear teeth). The data below are the results of the pitch carbon-analysis test for 19 parts. Soak Time 0.580 0.660 0.660 0.660 0.660 0.660 1.000 1.170 1.170 1.170 Pitch 0.013 0.016 0.015 0.016 0.015 0.016 0.014 0.021 0.018 0.019 Soak Time 1.170 1.170 1.170 1.200 2.000 2.000 2.200 2.200 2.200 Pitch 0.021 0.019 0.021 0.025 0.025 0.026 0.024 0.025 0.024 The following tables are the incomplete Regression Analysis generated using Microsoft Excel: Regression Statistics Multiple R 0.87718225 R Square 0.76944871 Adjusted R Square 0.75588687 Standard Error 0.00212326 Observations 19 ANOVA df SS MS Significance F Regression 1 0.00025578 0.00025578 56.736303 ? Residual 17 7.664E-05 4.5082E-06 Total 18 0.00033242 Coefficients Standard Error t Stat P-value Lower 95% Upper 95% Intercept ? 0.001175 9.84103423 ? 0.00909025 0.01405162

Heat treating is often used to carburize metal parts such as gears. The thickness of the carburized layer is considered an important feature of the gear, and it contributes to the overall reliability of the part. Because of the critical nature of this feature, a lab test is performed on each furnace load. The test is a destructive one, where an actual part is cross sectioned and soaked in a chemical for a period of time. This test involves running a carbon analysis on the surface of both the gear pitch (top of the gear tooth) and the gear root (between the gear teeth). The data below are the results of the pitch carbon-analysis test for 19 parts. Soak Time 0.580 0.660 0.660 0.660 0.660 0.660 1.000 1.170 1.170 1.170 Pitch 0.013 0.016 0.015 0.016 0.015 0.016 0.014 0.021 0.018 0.019 Soak Time 1.170 1.170 1.170 1.200 2.000 2.000 2.200 2.200 2.200 Pitch 0.021 0.019 0.021 0.025 0.025 0.026 0.024 0.025 0.024 The following tables are the incomplete Regression Analysis generated using Microsoft Excel: Regression Statistics Multiple R 0.87718225 R Square 0.76944871 Adjusted R Square 0.75588687 Standard Error 0.00212326 Observations 19 ANOVA df SS MS Significance F Regression 1 0.00025578 0.00025578 56.736303 ? Residual 17 7.664E-05 4.5082E-06 Total 18 0.00033242 Coefficients Standard Error t Stat P-value Lower 95% Upper 95% Intercept ? 0.001175 9.84103423 ? 0.00909025 0.01405162

Big Ideas Math A Bridge To Success Algebra 1: Student Edition 2015

1st Edition

ISBN:9781680331141

Author:HOUGHTON MIFFLIN HARCOURT

Publisher:HOUGHTON MIFFLIN HARCOURT

Chapter11: Data Analysis And Displays

Section11.2: Box-and-whisker Plots

Problem 6E

Related questions

Question

48

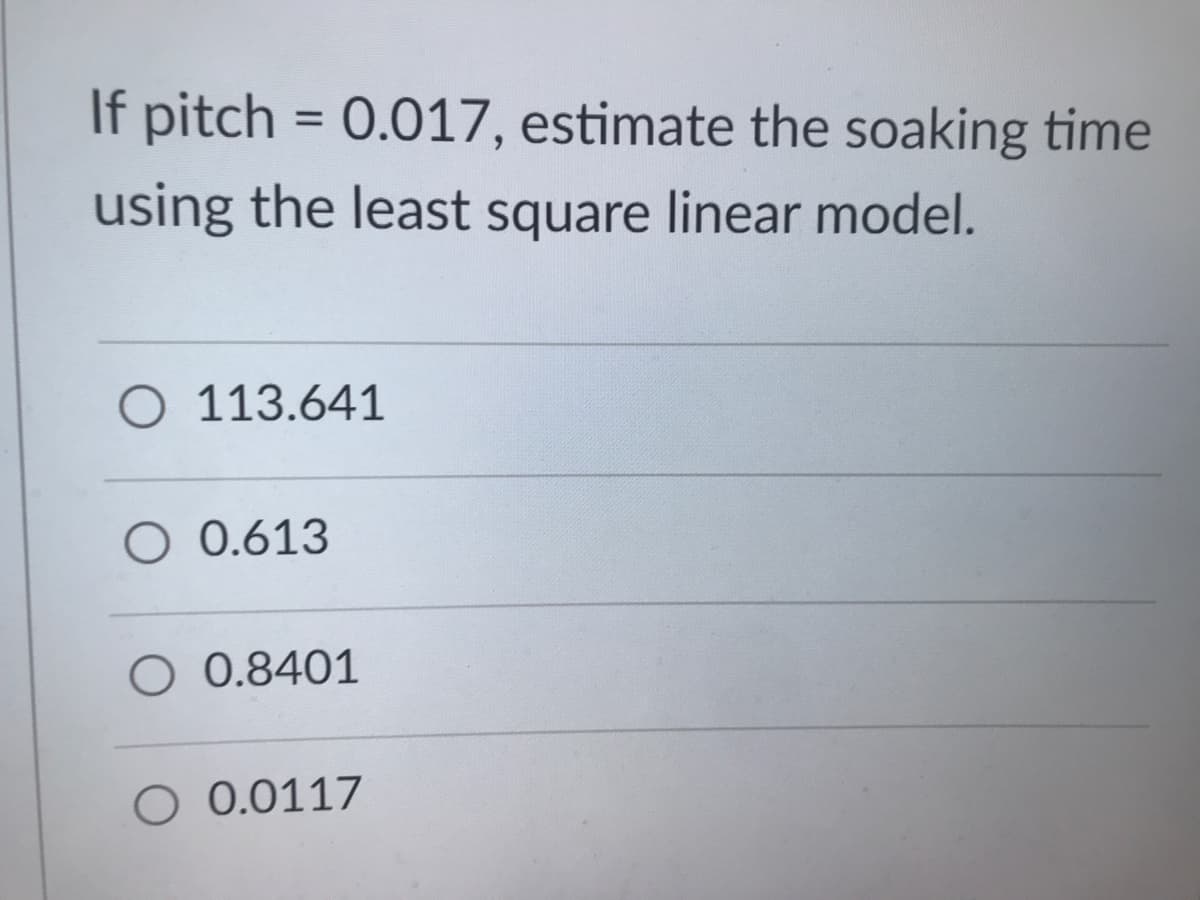

Transcribed Image Text:If pitch = 0.017, estimate the soaking time

using the least square linear model.

O 113.641

O 0.613

O 0.8401

O 0.0117

Transcribed Image Text:Heat treating is often used to carburize metal parts such as gears. The thickness of the carburized layer is considered an important feature of the gear, and it

contributes to the overall reliability of the part. Because of the critical nature of this feature, a lab test is performed on each furnace load. The test is a destructive

one, where an actual part is cross sectioned and soaked in a chemical for a period of time. This test involves running a carbon analysis on the surface of both the gear

pitch (top of the gear tooth) and the gear root (between the gear teeth). The data below are the results of the pitch carbon-analysis test for 19 parts.

Soak Time

0.580

0.660

0.660

0.660

0.660

0.660

1.000

1.170

1.170

1.170

Pitch

0.013

0.016

0.015

0.016

0.015

0.016

0.014

0.021

0.018

0.019

Soak Time

1.170

1.170

1.170

1.200

2.000

2.000

2.200

2.200

2.200

Pitch

0.021

0.019

0.021

0.025

0.025

0.026

0.024

0.025

0.024

The following tables are the incomplete Regression Analysis generated using Microsoft Excel:

Regression Statistics

Multiple R

0.87718225

R Square

0.76944871

Adjusted R Square

0.75588687

Standard Error

0.00212326

Observations

19

ANOVA

df

SS

MS

F

Significance F

Regression

1

0.00025578

0.00025578

56.736303

?

Residual

17

7.664E-05

4.5082E-06

Total

18

0.00033242

Coefficients

Standard Error

t Stat

P-value

Lower 95%

Upper 95%

Intercept

?

0.001175

9.84103423

?

0.00909025

0.01405162

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Recommended textbooks for you

Big Ideas Math A Bridge To Success Algebra 1: Stu…

Algebra

ISBN:

9781680331141

Author:

HOUGHTON MIFFLIN HARCOURT

Publisher:

Houghton Mifflin Harcourt

Linear Algebra: A Modern Introduction

Algebra

ISBN:

9781285463247

Author:

David Poole

Publisher:

Cengage Learning

Big Ideas Math A Bridge To Success Algebra 1: Stu…

Algebra

ISBN:

9781680331141

Author:

HOUGHTON MIFFLIN HARCOURT

Publisher:

Houghton Mifflin Harcourt

Linear Algebra: A Modern Introduction

Algebra

ISBN:

9781285463247

Author:

David Poole

Publisher:

Cengage Learning