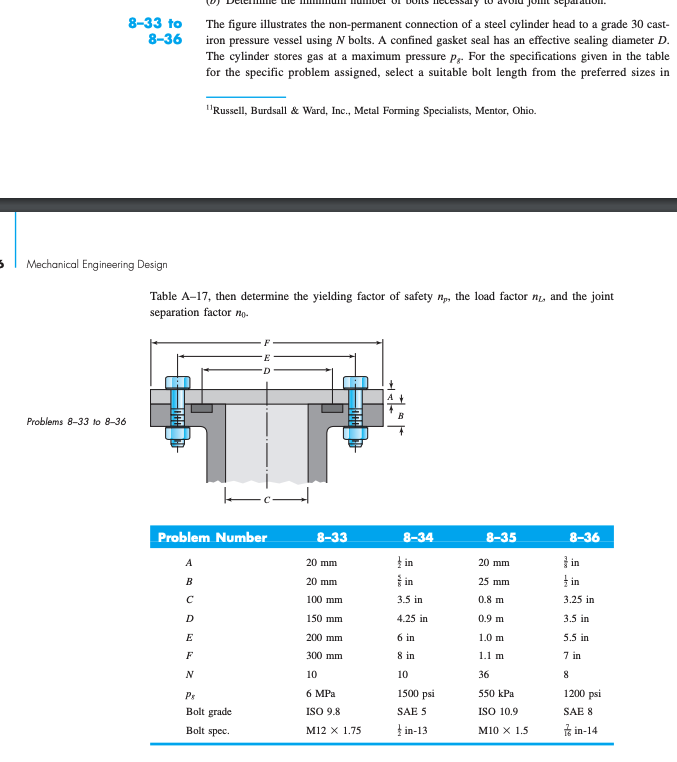

8-33 to 8-36 Mechanical Engineering Design The figure illustrates the non-permanent connection of a steel cylinder head to a grade 30 cast- iron pressure vessel using N bolts. A confined gasket seal has an effective sealing diameter D. The cylinder stores gas at a maximum pressure pr. For the specifications given in the table for the specific problem assigned, select a suitable bolt length from the preferred sizes in "Russell, Burdsall & Ward, Inc., Metal Forming Specialists, Mentor, Ohio. Table A-17, then determine the yielding factor of safety n,, the load factor n, and the joint separation factor no

8-33 to 8-36 Mechanical Engineering Design The figure illustrates the non-permanent connection of a steel cylinder head to a grade 30 cast- iron pressure vessel using N bolts. A confined gasket seal has an effective sealing diameter D. The cylinder stores gas at a maximum pressure pr. For the specifications given in the table for the specific problem assigned, select a suitable bolt length from the preferred sizes in "Russell, Burdsall & Ward, Inc., Metal Forming Specialists, Mentor, Ohio. Table A-17, then determine the yielding factor of safety n,, the load factor n, and the joint separation factor no

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Only Question 8-33, how does one use the preferred size?

Transcribed Image Text:5

8-33 to

8-36

Mechanical Engineering Design

Problems 8-33 to 8-36

The figure illustrates the non-permanent connection of a steel cylinder head to a grade 30 cast-

iron pressure vessel using N bolts. A confined gasket seal has an effective sealing diameter D.

The cylinder stores gas at a maximum pressure pg. For the specifications given in the table

for the specific problem assigned, select a suitable bolt length from the preferred sizes in

Table A-17, then determine the yielding factor of safety n,, the load factor ₁, and the joint

separation factor no.

A

B

C

D

E

"Russell, Burdsall & Ward, Inc., Metal Forming Specialists, Mentor, Ohio.

Problem Number

F

N

Ps

Bolt grade

Bolt spec.

8-33

20 mm

20 mm

100 mm

150 mm

200 mm

300 mm

10

6 MPa

ISO 9.8

M12 x 1.75

8-34

in

in

3.5 in

4.25 in

6 in

8 in

10

1500 psi

SAE 5

in-13

8-35

20 mm.

25 mm

0.8 m

0.9 m

1.0 m

1.1 m

36

550 kPa

ISO 10.9

M10 X 1.5

8-36

in

in

3.25 in

3.5 in

5.5 in

7 in

8

mix

1200 psi

SAE 8

in-14

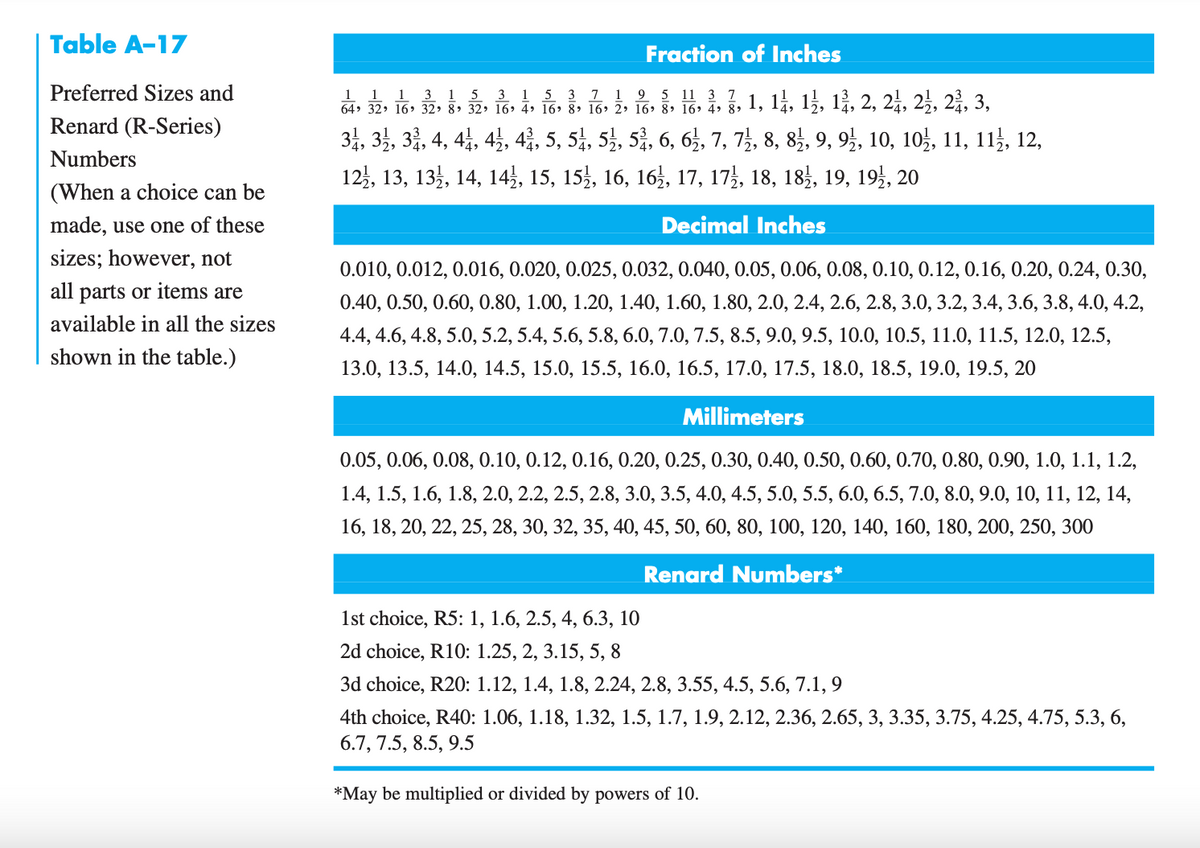

Transcribed Image Text:Table A-17

Preferred Sizes and

Renard (R-Series)

Numbers

(When a choice can be

made, use one of these

sizes; however, not

all parts or items are

available in all the sizes

shown in the table.)

Fraction of Inches

1

1

1 3 15

3

15

3

7 1

9

5 11 3 7

64, 32, 16, 32, §, 32, 16, 4, 16, 8, 16, 2, 16, §, 16, 4, 3, 1, 14, 1½, 13, 2, 2¼, 2½, 2³, 3,

34, 31, 3³, 4, 41, 42, 4³, 5, 51, 52, 5³, 6, 61⁄2, 7, 71⁄2, 8, 8½, 9, 9½, 10, 10¹, 11, 111, 12,

12/½, 13, 13½, 14, 14½, 15, 15½, 16, 16½, 17, 17½⁄2, 18, 181⁄2, 19, 19½, 20

Decimal Inches

0.010, 0.012, 0.016, 0.020, 0.025, 0.032, 0.040, 0.05, 0.06, 0.08, 0.10, 0.12, 0.16, 0.20, 0.24, 0.30,

0.40, 0.50, 0.60, 0.80, 1.00, 1.20, 1.40, 1.60, 1.80, 2.0, 2.4, 2.6, 2.8, 3.0, 3.2, 3.4, 3.6, 3.8, 4.0, 4.2,

4.4, 4.6, 4.8, 5.0, 5.2, 5.4, 5.6, 5.8, 6.0, 7.0, 7.5, 8.5, 9.0, 9.5, 10.0, 10.5, 11.0, 11.5, 12.0, 12.5,

13.0, 13.5, 14.0, 14.5, 15.0, 15.5, 16.0, 16.5, 17.0, 17.5, 18.0, 18.5, 19.0, 19.5, 20

Millimeters

0.05, 0.06, 0.08, 0.10, 0.12, 0.16, 0.20, 0.25, 0.30, 0.40, 0.50, 0.60, 0.70, 0.80, 0.90, 1.0, 1.1, 1.2,

1.4, 1.5, 1.6, 1.8, 2.0, 2.2, 2.5, 2.8, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 8.0, 9.0, 10, 11, 12, 14,

16, 18, 20, 22, 25, 28, 30, 32, 35, 40, 45, 50, 60, 80, 100, 120, 140, 160, 180, 200, 250, 300

Renard Numbers*

1st choice, R5: 1, 1.6, 2.5, 4, 6.3, 10

2d choice, R10: 1.25, 2, 3.15, 5, 8

3d choice, R20: 1.12, 1.4, 1.8, 2.24, 2.8, 3.55, 4.5, 5.6, 7.1, 9

4th choice, R40: 1.06, 1.18, 1.32, 1.5, 1.7, 1.9, 2.12, 2.36, 2.65, 3, 3.35, 3.75, 4.25, 4.75, 5.3, 6,

6.7, 7.5, 8.5, 9.5

*May be multiplied or divided by powers of 10.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 3 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

How did you determine to round up to 55 mm if the table never mention anything about 55 mm?

Solution

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY