into one. Taylor's scientific management did away with this by making planning the job of management and production the job of labor. To keep quality from falling through the cracks, it was necessary to create a separate quality depart- ment. Such departments had shaky beginnings, and just who was responsible for quality became a clouded issue. As the volume and complexity of manufacturing grew, quality became an increasingly difficult issue. Volume and complexity together gave birth to quality engineering in the 1920s and reliability engineering in the 1950s. Quality engi- neering, in turn, resulted in the use of statistical methods in the control of quality, which eventually led to the concepts of control charts and statistical process control, which are now fundamental aspects of the total quality approach. Reliability engineering emerged in the 1950s. It began a trend toward moving quality control away from the traditional after-the-fact approach and toward inserting it throughout the design and production processes. However, for the most part, quality control in the 1950s and 1960s involved inspections that resulted in nothing more than cutting out bad parts. World War II had an impact on quality that is still being felt. In general, the effect was negative for the United

into one. Taylor's scientific management did away with this by making planning the job of management and production the job of labor. To keep quality from falling through the cracks, it was necessary to create a separate quality depart- ment. Such departments had shaky beginnings, and just who was responsible for quality became a clouded issue. As the volume and complexity of manufacturing grew, quality became an increasingly difficult issue. Volume and complexity together gave birth to quality engineering in the 1920s and reliability engineering in the 1950s. Quality engi- neering, in turn, resulted in the use of statistical methods in the control of quality, which eventually led to the concepts of control charts and statistical process control, which are now fundamental aspects of the total quality approach. Reliability engineering emerged in the 1950s. It began a trend toward moving quality control away from the traditional after-the-fact approach and toward inserting it throughout the design and production processes. However, for the most part, quality control in the 1950s and 1960s involved inspections that resulted in nothing more than cutting out bad parts. World War II had an impact on quality that is still being felt. In general, the effect was negative for the United

Chapter11: Human Resource Management

Section: Chapter Questions

Problem 2CTQ: Do you think that a Holacracy can be compared to a consulting company? How are they similar,s and...

Related questions

Question

Quality engineering question

Please read the pages and make a short and clear summary of them with your own words please. Mention only the necessary important parts

Also, you will put your comments and ideas about the topic briefly

It is what you understand

You must prepare neat the summary

Thank you

2nd picture is a continuation of the first one

Transcribed Image Text:into one. Taylor's scientific management did away with this

by making planning the job of management and production

the job of labor. To keep quality from falling through the

cracks, it was necessary to create a separate quality depart-

ment. Such departments had shaky beginnings, and just who

was responsible for quality became a clouded issue.

As the volume and complexity of manufacturing grew,

quality became an increasingly difficult issue. Volume and

complexity together gave birth to quality engineering in the

1920s and reliability engineering in the 1950s. Quality engi-

neering, in turn, resulted in the use of statistical methods in

the control of quality, which eventually led to the concepts

of control charts and statistical process control, which are now

fundamental aspects of the total quality approach.

Reliability engineering emerged in the 1950s. It began a

trend toward moving quality control away from the traditional

after-the-fact approach and toward inserting it throughout the

design and production processes. However, for the most part,

quality control in the 1950s and 1960s involved inspections

that resulted in nothing more than cutting out bad parts.

World War II had an impact on quality that is still

being felt. In general, the effect was negative for the United

States and positive for Japan. Because of the urgency to

meet production schedules during the war, U.S. companies

focused more on meeting delivery dates than on quality.

This approach became a habit that carried over even after

the war.

Japanese companies, on the other hand, were forced to

learn to compete with the rest of the world in the produc-

tion of nonmilitary goods. At first, their attempts were un-

successful, and "Made in Japan" remained synonymous with

poor quality, as it had been before World War II. Around

1950, however, Japan decided to get serious about quality

and establishing ways to produce quality products.

Japanese manufacturers overcame a reputation for pro-

ducing cheap, shabby products and developed a reputation

as world leaders in the production of quality products. More

than any other single factor, it was the Japanese miracle-

which was not a miracle at all but the result of a concerted

effort that took 20 years to really bear fruit-that got the rest

of the world to focus on quality. When Western companies

finally realized that quality was the key factor in global com-

petition, they responded. Unfortunately, their first responses

were the opposite of what was needed.

In spite of these early negative reactions, Western com-

panies began to realize that the key to competing in the global

marketplace was to improve quality. With this realization, the

total quality movement finally began to gain momentum.

Transcribed Image Text:ment is the separation of planning and execution A ge-

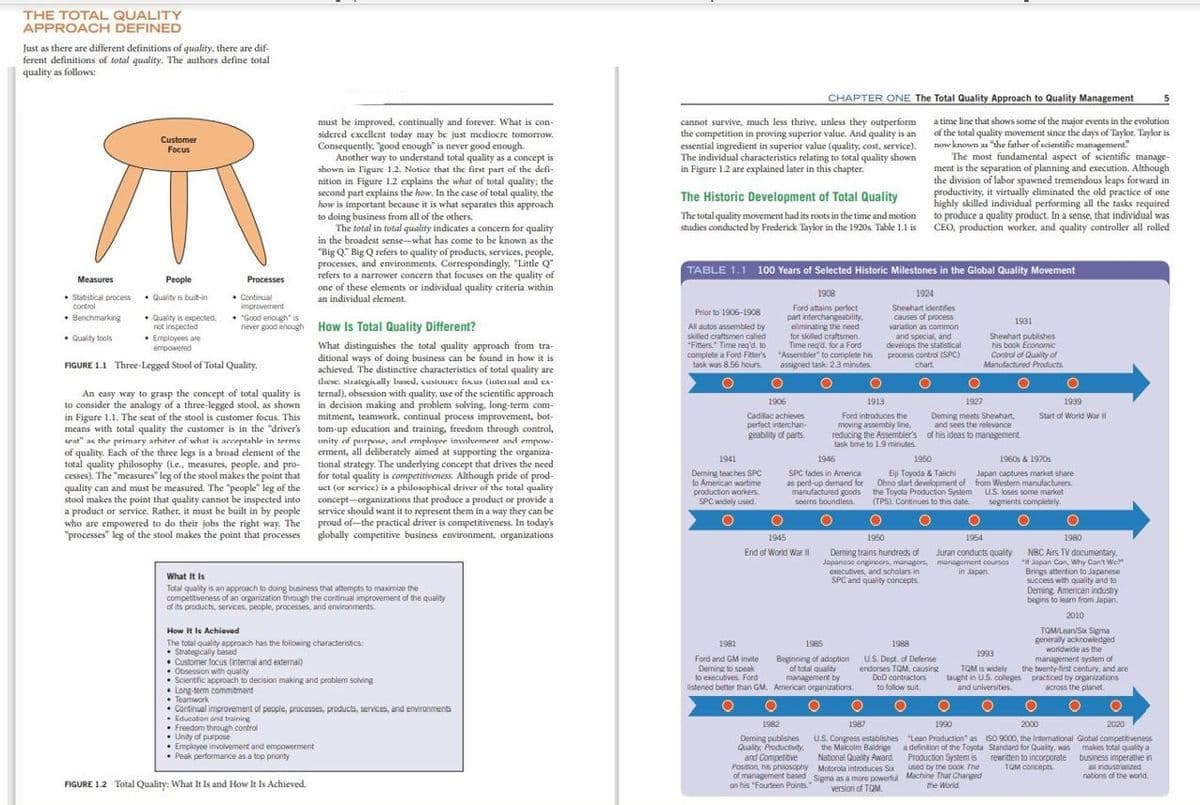

THE TOTAL QUALITY

APPROACH DEFINED

Just as there are different definitions of quality, there are dif-

ferent definitions of total quality. The authors define total

quality as follows:

CHAPTER ONE The Total Quality Approach to Quality Management

cannot survive, much less thrive, unless they outperform a time line that shows some of the major events in the evolution

the competition in proving superior value. And quality is an of the total quality movement since the days of Taylor. Taylor is

must be improved, continually and forever. What is con-

sidcred excellent today may be just mediocre tomorrow.

Consequently, "good enough" is never good enough.

Another way to understand total quality as a concept is

shown in ligure 1.2. Notice that the first part of the defi-

nition in Figure 1.2 explains the what of total quality: the

second part explains the how. In the case of total quality, the

how is important because it is what separates this approach

to doing business from all of the others.

The total in total quality indicates a concern for quality

in the broadest sense-what has come to be known as the

"Big Q" Big Q refers to quality of products, services, people,

processes, and environments. Correspondingly. "Little Q"

refers to a narrower concern that focuses on the quality of

one of these elements or individual quality criteria within

an individual element.

Customer

now known a "the father of scientific management"

The most fundamental aspect of scientific

ment is the separation of planning and execution. Although

the division of labor spawned tremendous leaps forward in

productivity, it virtually eliminated the old practice of one

highly skilled individual performing all the tasks required

to produce a quality product. In a sense, that individual was

CEO, production worker, and quality controller all rolled

essential ingredient in superior value (quality, cost, service).

The individual characteristics relating to total quality shown

in Figure 1.2 are explained later in this chapter.

Focus

The Historic Development of Total Quality

The total quality movement had its roots in the time and motion

studies conducted by Frederick Taylor in the 1920s. Table 1.1 is

TABLE 1.1 100 Years of Selected Historic Milestones in the Global Quality Movement

Measures

People

Processes

1908

1924

• Continual

improvement

• "Good enough" is

• Statistical proces • Quality is buit-in

control

Ford attains perfect

part interchangeability.

eliminating the need

for skilled craftsmen.

Time reg'd. for a Ford

complete a Ford Fitter's "Assembler to complete his

assigned task: 2.3 minutes

Shewhart identifies

Prior to 1906-1908

• Benchmarking

• Quality is expected,

not inspected

causes of process

variation as common

and special, and

develops the statistical

process control (SPC)

1931

never good encugh How Is Total Quality Different?

All autos assembled by

skiled craftsmen called

Fitters." Time req'd. to

Shewhart publishes

his book Economic

• Quality tools

• Employees are

empowered

What distinguishes the total quality approach from tra-

ditional ways of doing business can be found in how it is

achieved. The distinctive characteristics of total quality are

diese: strategically bascl, custuuer furus (isterual aud ea-

An casy way to grasp the concept of total quality is ternal), obsession with quality, use of the scientific approach

in decision making and problem solving, long-term com-

mitment, teamwork, continual process improvement, bot-

tom-up education and training, freedom through control,

unity of purpoer, and employre invnlvement and empow-

erment, all deliberately aimed at supporting the organiza-

tional strategy. The underlying concept that drives the need

for total quality is competitiveness. Although pride of prod-

uct (or acrvice) ia a philosophical driver of the total quality

concept-organizations that produce a product or provide a

service should want it to represent them in a way they can be

proud of-the practical driver is competitiveness. In today's

"processes" leg of the stool makes the point that processes globally competitive business environment, organizations

Contral of Quality of

Manutactured Products

FIGURE 1.1 Three-Legged Stool of Total Quality.

task was 8.56 hours

chart.

1906

1913

1927

1939

to consider the analogy of a three-legged stool, as shown

in Figure 1.1. The seat of the stool is customer focus. This

means with total quality the customer is in the "driver's

srat" as the primary arhiter of what is acceptahle in terme

of quality. Each of the three legs is a broad clement of the

total quality philosophy (ie., measures, people, and pro-

cesses). The "measures" leg of the stool makes the point that

quality can and must be measured. The "people" leg of the

stool makes the point that quality cannot be inspected into

a product or service. Rather, it must be built in by people

who are empowered to do their jobs the right way. The

Cadilac achieves

perfect interchan-

geability of parts.

Ford introduces the

moving assembly line,

reducing the Assembler's of his ideas to management.

task time to 19 minutes

Deming meets Shewhart,

and sees the relevance

Start of World War I

1941

1946

1950

1960s & 1970s

Deming teaches SPC

to American wartime

production workers.

SPC widely used.

Eiji Toyoda & Taichi

as pent-up demand for Ohno start developmenit of from Western manufacturers.

SPC fades in America

Japan captures market share

manufactured goods the Toyota Production System

seerns boundless.

U.S. loses some market

segments completely.

(TPS). Continues to this date.

1945

1950

1954

1980

End of World War I

NBC Airs TV documentary,

Japancse enginocra, managers, monagoment courses Japan Con, Why Can't We

Brings attertion to Japanese

success with quality and to

Deming. American industry

begins to learn from Japan

Deming trains hundreds of

Juran conducts quality

executives, and scholars in

SPC and quality concepts.

in Japan.

What It Is

Total quality is an approach to doing business that attempts to maximize the

competitiveness of an organization through the continual improvement of the quality

of its products, services, people, processes, and environments.

2010

TOM/Lean/Sx Sigma

generally acknowiedged

worldwide as the

How It ls Achieved

The total quality approach has the following characteristics.

• Strategically based

• Customer focus (internal and extermal)

• Obsession with quality

• Scientfic approach to decision making and problem solving

• Long-term commitment

• Tearmwork

• Continual improvement of people, pracesses, products, services, and environments

Education ond training

• Freedom through control

Unity of purpose

• Employee involvement and empowerment

• Peak performance as a top pricrity

1981

1985

1988

1993

Ford and GM invite

Deming to speak

to executives. Ford

listened better than GM. American organizations.

Beginning of adoption

of total quality

management by

U.S. Dept. of Defense

endorses TOM, causing

DoD contractors

to follow suit.

management system of

the twenty-first century, and are

taught in U.S. coleges practiced by organizations

across the planet.

TOM is widely

and universities

1982

1987

1990

2000

2020

Deming publishes

Quality, Productivity.

and Competibve

Posmon, ns phiosopny Motorola introduces Sa ed by the booK The

of management based Sigma as a more powerful Machine That Changed

on his "Fourteen Points.

U.S. Congress establishes "Lean Production" as ISO 9000, the International Global competitiveness

the Malcoim Baldrige a definition of the Toyota Standard for Quality, was makes total qualty a

National Quality Award. Production System is

rewritten to incorporate

TOM concepts

business imperative in

a maustraized

nations of the world.

FIGURE 1.2 Total Quality: What It Is and How It Is Achieved.

version of TOM.

the World

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you