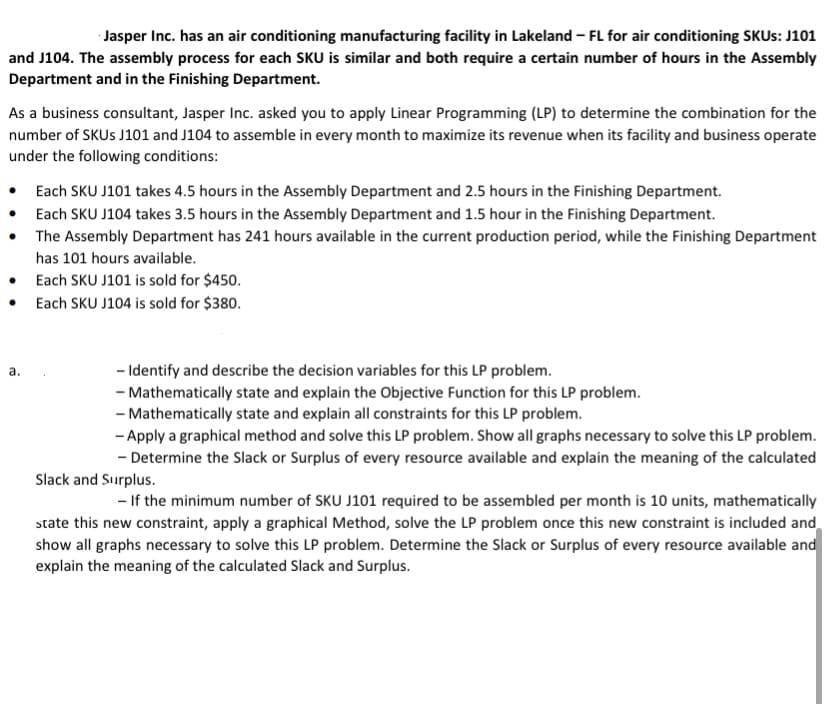

Jasper Inc. has an air conditioning manufacturing facility in Lakeland - FL for air conditioning SKUS: J101 and J104. The assembly process for each SKU is similar and both require a certain number of hours in the Assembly Department and in the Finishing Department. As a business consultant, Jasper Inc. asked you to apply Linear Programming (LP) to determine the combination for the number of SKUS J101 and J104 to assemble in every month to maximize its revenue when its facility and business operate under the following conditions: • Each SKU J101 takes 4.5 hours in the Assembly Department and 2.5 hours in the Finishing Department. Each SKU J104 takes 3.5 hours in the Assembly Department and 1.5 hour in the Finishing Department. The Assembly Department has 241 hours available in the current production period, while the Finishing Department has 101 hours available. Each SKU J101 is sold for $450. Each SKU J104 is sold for $380. - Identify and describe the decision variables for this LP problem. - Mathematically state and explain the Objective Function for this LP problem. - Mathematically state and explain all constraints for this LP problem. - Apply a graphical method and solve this LP problem. Show all graphs necessary to solve this LP problem. а. - Determine the Slack or Surplus of every resource available and explain the meaning of the calculated Slack and Surplus. - If the minimum number of SKU J101 required to be assembled per month is 10 units, mathematically state this new constraint, apply a graphical Method, solve the LP problem once this new constraint is included and

Jasper Inc. has an air conditioning manufacturing facility in Lakeland - FL for air conditioning SKUS: J101 and J104. The assembly process for each SKU is similar and both require a certain number of hours in the Assembly Department and in the Finishing Department. As a business consultant, Jasper Inc. asked you to apply Linear Programming (LP) to determine the combination for the number of SKUS J101 and J104 to assemble in every month to maximize its revenue when its facility and business operate under the following conditions: • Each SKU J101 takes 4.5 hours in the Assembly Department and 2.5 hours in the Finishing Department. Each SKU J104 takes 3.5 hours in the Assembly Department and 1.5 hour in the Finishing Department. The Assembly Department has 241 hours available in the current production period, while the Finishing Department has 101 hours available. Each SKU J101 is sold for $450. Each SKU J104 is sold for $380. - Identify and describe the decision variables for this LP problem. - Mathematically state and explain the Objective Function for this LP problem. - Mathematically state and explain all constraints for this LP problem. - Apply a graphical method and solve this LP problem. Show all graphs necessary to solve this LP problem. а. - Determine the Slack or Surplus of every resource available and explain the meaning of the calculated Slack and Surplus. - If the minimum number of SKU J101 required to be assembled per month is 10 units, mathematically state this new constraint, apply a graphical Method, solve the LP problem once this new constraint is included and

Algebra for College Students

10th Edition

ISBN:9781285195780

Author:Jerome E. Kaufmann, Karen L. Schwitters

Publisher:Jerome E. Kaufmann, Karen L. Schwitters

Chapter12: Algebra Of Matrices

Section12.4: Systems Of Linear Inequalities Linear Programming

Problem 44PS

Related questions

Question

help please

Transcribed Image Text:Jasper Inc. has an air conditioning manufacturing facility in Lakeland – FL for air conditioning SKUS: J101

and J104. The assembly process for each SKU is similar and both require a certain number of hours in the Assembly

Department and in the Finishing Department.

As a business consultant, Jasper Inc. asked you to apply Linear Programming (LP) to determine the combination for the

number of SKUS J101 and J104 to assemble in every month to maximize its revenue when its facility and business operate

under the following conditions:

Each SKU J101 takes 4.5 hours in the Assembly Department and 2.5 hours in the Finishing Department.

Each SKU J104 takes 3.5 hours in the Assembly Department and 1.5 hour in the Finishing Department.

The Assembly Department has 241 hours available in the current production period, while the Finishing Department

has 101 hours available.

• Each SKU J101 is sold for $450.

Each SKU J104 is sold for $380.

- Identify and describe the decision variables for this LP problem.

- Mathematically state and explain the Objective Function for this LP problem.

- Mathematically state and explain all constraints for this LP problem.

- Apply a graphical method and solve this LP problem. Show all graphs necessary to solve this LP problem.

- Determine the Slack or Surplus of every resource available and explain the meaning of the calculated

Slack and Surplus.

- If the minimum number of SKU J101 required to be assembled per month is 10 units, mathematically

state this new constraint, apply a graphical Method, solve the LP problem once this new constraint is included and

show all graphs necessary to solve this LP problem. Determine the Slack or Surplus of every resource available and

explain the meaning of the calculated Slack and Surplus.

a.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Algebra for College Students

Algebra

ISBN:

9781285195780

Author:

Jerome E. Kaufmann, Karen L. Schwitters

Publisher:

Cengage Learning

College Algebra (MindTap Course List)

Algebra

ISBN:

9781305652231

Author:

R. David Gustafson, Jeff Hughes

Publisher:

Cengage Learning

Algebra for College Students

Algebra

ISBN:

9781285195780

Author:

Jerome E. Kaufmann, Karen L. Schwitters

Publisher:

Cengage Learning

College Algebra (MindTap Course List)

Algebra

ISBN:

9781305652231

Author:

R. David Gustafson, Jeff Hughes

Publisher:

Cengage Learning