JL.53 Bob's Bumpers has a repetitive manufacturing facility in Kentucky that makes automobile bumpers and other auto parts. The facility operates 350 days per year and has annual demand of 75,000 bumpers. They can produce up to 330 each day. It costs $71 to set up the production line to produce bumpers. The cost of each bumper is $148 and annual he costs are $37 per unit. Setup labor cost is $25 per hour. What is the optimal size of the production run for bumpers? (Display your answer to the nearest whole number.) 189 Based on your answer to the previous question, and assuming the manufacturer holds no safety stock, what would be ti average inventory for these bumpers? (Display your answer to the nearest whole number.) Number

JL.53 Bob's Bumpers has a repetitive manufacturing facility in Kentucky that makes automobile bumpers and other auto parts. The facility operates 350 days per year and has annual demand of 75,000 bumpers. They can produce up to 330 each day. It costs $71 to set up the production line to produce bumpers. The cost of each bumper is $148 and annual he costs are $37 per unit. Setup labor cost is $25 per hour. What is the optimal size of the production run for bumpers? (Display your answer to the nearest whole number.) 189 Based on your answer to the previous question, and assuming the manufacturer holds no safety stock, what would be ti average inventory for these bumpers? (Display your answer to the nearest whole number.) Number

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter7: Nonlinear Optimization Models

Section: Chapter Questions

Problem 56P

Related questions

Question

1

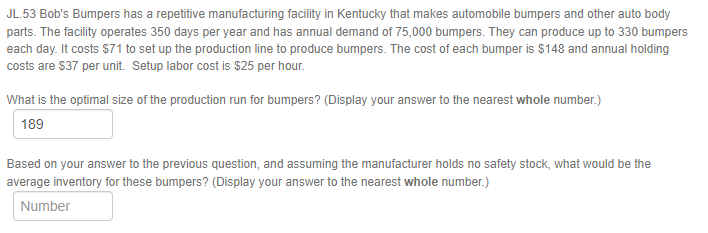

Transcribed Image Text:JL.53 Bob's Bumpers has a repetitive manufacturing facility in Kentucky that makes automobile bumpers and other auto body

parts. The facility operates 350 days per year and has annual demand of 75,000 bumpers. They can produce up to 330 bumpers

each day. It costs $71 to set up the production line to produce bumpers. The cost of each bumper is $148 and annual holding

costs are $37 per unit. Setup labor cost is $25 per hour.

What is the optimal size of the production run for bumpers? (Display your answer to the nearest whole number.)

189

Based on your answer to the previous question, and assuming the manufacturer holds no safety stock, what would be the

average inventory for these bumpers? (Display your answer to the nearest whole number.)

Number

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,