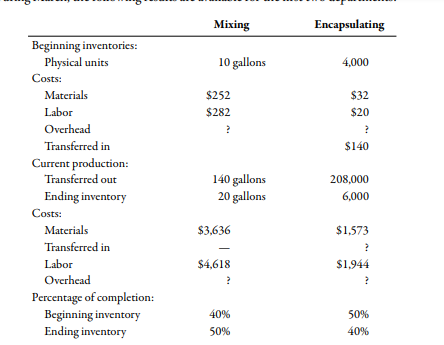

Mixing Encapsulating Beginning inventories: Physical units 10 gallons 4,000 Costs: Materials $252 $32 Labor $282 $20 Overhead Transferred in $140 Current production: Transferred out 140 gallons 20 gallons 208,000 Ending inventory 6,000 Costs: Materials $3,636 $1,573 Transferred in Labor $4,618 $1,944 Overhead Percentage of completion: Beginning inventory Ending inventory 40% 50% 50% 40%

Process Costing

Process costing is a sort of operation costing which is employed to determine the value of a product at each process or stage of producing process, applicable where goods produced from a series of continuous operations or procedure.

Job Costing

Job costing is adhesive costs of each and every job involved in the production processes. It is an accounting measure. It is a method which determines the cost of specific jobs, which are performed according to the consumer’s specifications. Job costing is possible only in businesses where the production is done as per the customer’s requirement. For example, some customers order to manufacture furniture as per their needs.

ABC Costing

Cost Accounting is a form of managerial accounting that helps the company in assessing the total variable cost so as to compute the cost of production. Cost accounting is generally used by the management so as to ensure better decision-making. In comparison to financial accounting, cost accounting has to follow a set standard ad can be used flexibly by the management as per their needs. The types of Cost Accounting include – Lean Accounting, Standard Costing, Marginal Costing and Activity Based Costing.

Weighted Average Method, Nonuniform Inputs, Multiple

Departments

Benson Pharmaceuticals uses a process-costing system to compute the unit costs of the overthe-counter cold remedies that it produces. It has three departments: mixing, encapsulating,

and bottling. In mixing, the ingredients for the cold capsules are measured, sifted, and blended

(with materials assumed to be uniformly added throughout the process). The mix is transferred

out in gallon containers. The encapsulating department takes the powdered mix and places it in

capsules (which are necessarily added at the beginning of the process). One gallon of powdered

mix converts into 1,500 capsules. After the capsules are filled and polished, they are transferred

to bottling, where they are placed in bottles that are then affixed with a safety seal, lid, and label.

Each bottle receives 50 capsules.

During March, the following results are available for the first two departments:

Overhead in both departments is applied as a percentage of direct labor costs. In the mixing

department, overhead is 200% of direct labor. In the encapsulating department, the overhead

rate is 150% of direct labor.

Required:

1. Prepare a production report for the mixing department using the weighted average

method. Follow the five steps outlined in the chapter. (Note: Round to two decimal places

for the unit cost.)

2. Prepare a production report for the encapsulating department using the weighted average

method. Follow the five steps outlined in the chapter. (Note: Round to four decimal places

for the unit cost.)

3. CONCEPTUAL CONNECTION Explain why the weighted average method is easier to use

than FIFO. Explain when weighted average will give about the same results as FIFO.

Problem 6-68 (Appendix 6A) First-In, First-Out Method

Step by step

Solved in 2 steps with 3 images