Modify the RedBrand example so that all flows must be from plants to warehouses and from warehouses to customers. Disallow all other arcs. How much does this restriction cost RedBrand, relative to the original optimal shipping cost?

Modify the RedBrand example so that all flows must be from plants to warehouses and from warehouses to customers. Disallow all other arcs. How much does this restriction cost RedBrand, relative to the original optimal shipping cost?

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Modify the RedBrand example so that all flows must be from plants to warehouses and from warehouses to customers. Disallow all other arcs. How much does this restriction cost RedBrand, relative to the original optimal shipping cost?

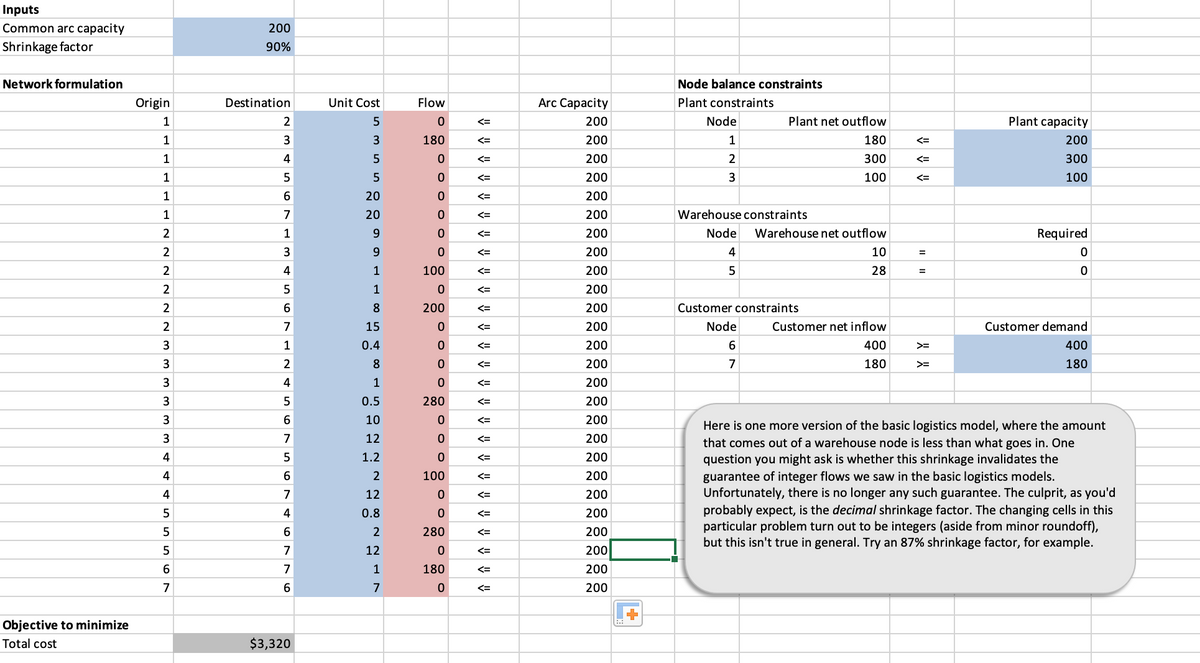

Transcribed Image Text:Inputs

Common arc capacity

200

Shrinkage factor

90%

Network formulation

Node balance constraints

%3D

Origin

Destination

Unit Cost

Flow

Arc Capacity

Plant constraints

1

2

200

Node

Plant net outflow

Plant capacity

1

180

<=

200

1

180

<=

200

1

4

200

300

<=

300

1

<=

200

3

100

<=

100

1

6

20

<=

200

1

7

20

200

Warehouse constraints

2

1

200

Node

Warehouse net outflow

Required

2

200

4

10

%3D

2

4

1

100

200

28

%3D

2

1

<=

200

8.

200

200

Customer constraints

2

7

15

<=

200

Node

Customer net inflow

Customer demand

1

0.4

<=

200

400

>=

400

3

2

8

<=

200

7

180

180

4

1

<=

200

0.5

280

200

10

200

Here is one more version of the basic logistics model, where the amount

7

12

200

that comes out of a warehouse node is less than what goes in. One

question you might ask is whether this shrinkage invalidates the

guarantee of integer flows we saw in the basic logistics models.

Unfortunately, there is no longer any such guarantee. The culprit, as you'd

probably expect, is the decimal shrinkage factor. The changing cells in this

particular problem turn out to be integers (aside from minor roundoff),

but this isn't true in general. Try an 87% shrinkage factor, for example.

4

5

1.2

200

4

2

100

<=

200

7

12

<=

200

5

4

0.8

200

5

6

2

280

<=

200

5

7

12

<=

200

7

1

180

<=

200

7

6

7

200

Objective to minimize

Total cost

$3,320

O o O O o O O O

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.