Name of Activity or Account Classificatlon by Activity level Acquiring material . Batch Inspecting incoming materials Batch Moving materials . Batch Planning production Batch Processing special orders Batch Processing supplier invoices Batch Receiving material. Batch Scheduling production Batch Inspecting production processes Batch Processing purchase orders Building occupancy Batch Facility Depreciation Facility General management Facility Facility Maintaining facilities Managing the environment Facility Assuring quality Product Sustaining Expediting Product Sustaining Maintaining tools and dies Maintaining/improving production processes Product Sustaining Product Sustaining Product Sustaining Product Sustaining Managing human resources Managing waste disposal Processing payroll Product Sustaining Processing production information Product Sustaining Providing product cost Product Sustaining Setting manufacturing methods Product Sustaining Supervising production. Product Sustaining Sustaining accounting Maintaining production equipment Product Sustaining Product Sustaining Direct-labor allowances Unit Direct-labor fringes Unit Utilities (equipment) Unit Overtime (hourly) Unit Rework. Unit Shift differential Unit Spoilage Unit

Name of Activity or Account Classificatlon by Activity level Acquiring material . Batch Inspecting incoming materials Batch Moving materials . Batch Planning production Batch Processing special orders Batch Processing supplier invoices Batch Receiving material. Batch Scheduling production Batch Inspecting production processes Batch Processing purchase orders Building occupancy Batch Facility Depreciation Facility General management Facility Facility Maintaining facilities Managing the environment Facility Assuring quality Product Sustaining Expediting Product Sustaining Maintaining tools and dies Maintaining/improving production processes Product Sustaining Product Sustaining Product Sustaining Product Sustaining Managing human resources Managing waste disposal Processing payroll Product Sustaining Processing production information Product Sustaining Providing product cost Product Sustaining Setting manufacturing methods Product Sustaining Supervising production. Product Sustaining Sustaining accounting Maintaining production equipment Product Sustaining Product Sustaining Direct-labor allowances Unit Direct-labor fringes Unit Utilities (equipment) Unit Overtime (hourly) Unit Rework. Unit Shift differential Unit Spoilage Unit

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter2: Basic Cost Management Concepts

Section: Chapter Questions

Problem 30P: The following items are associated with a traditional cost accounting information system, an...

Related questions

Question

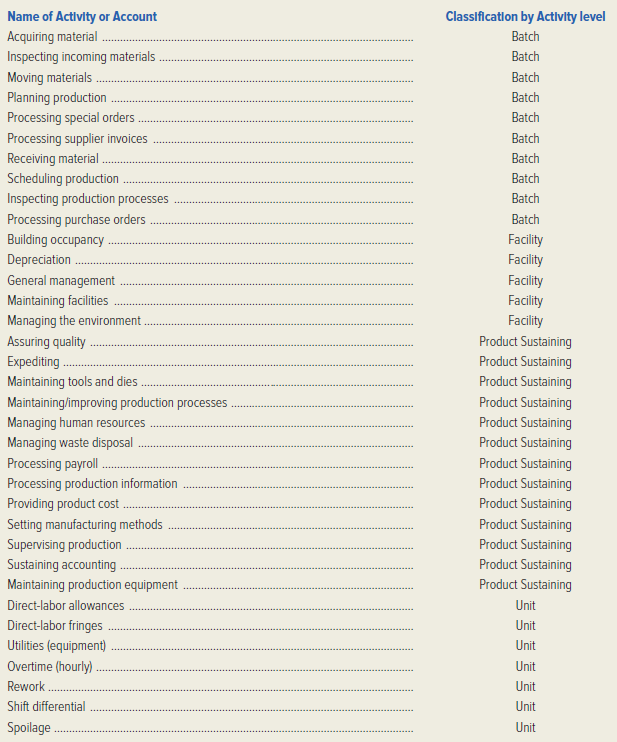

United Technologies Corporation implemented activity-based costing in two of its subsidiaries: Otis Elevator Company and Carrier Corporation. The following table shows 27 activities and eight accounts identified at Carrier, along with the classification determined by the ABC project team.12

Required: Choose two activities or accounts from each of the four classifications and explain why you agree or disagree with the ABC project team’s classification.

Transcribed Image Text:Name of Activity or Account

Classificatlon by Activity level

Acquiring material .

Batch

Inspecting incoming materials

Batch

Moving materials .

Batch

Planning production

Batch

Processing special orders

Batch

Processing supplier invoices

Batch

Receiving material.

Batch

Scheduling production

Batch

Inspecting production processes

Batch

Processing purchase orders

Building occupancy

Batch

Facility

Depreciation

Facility

General management

Facility

Facility

Maintaining facilities

Managing the environment

Facility

Assuring quality

Product Sustaining

Expediting

Product Sustaining

Maintaining tools and dies

Maintaining/improving production processes

Product Sustaining

Product Sustaining

Product Sustaining

Product Sustaining

Managing human resources

Managing waste disposal

Processing payroll

Product Sustaining

Processing production information

Product Sustaining

Providing product cost

Product Sustaining

Setting manufacturing methods

Product Sustaining

Supervising production.

Product Sustaining

Sustaining accounting

Maintaining production equipment

Product Sustaining

Product Sustaining

Direct-labor allowances

Unit

Direct-labor fringes

Unit

Utilities (equipment)

Unit

Overtime (hourly)

Unit

Rework.

Unit

Shift differential

Unit

Spoilage

Unit

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

EBK CONTEMPORARY FINANCIAL MANAGEMENT

Finance

ISBN:

9781337514835

Author:

MOYER

Publisher:

CENGAGE LEARNING - CONSIGNMENT