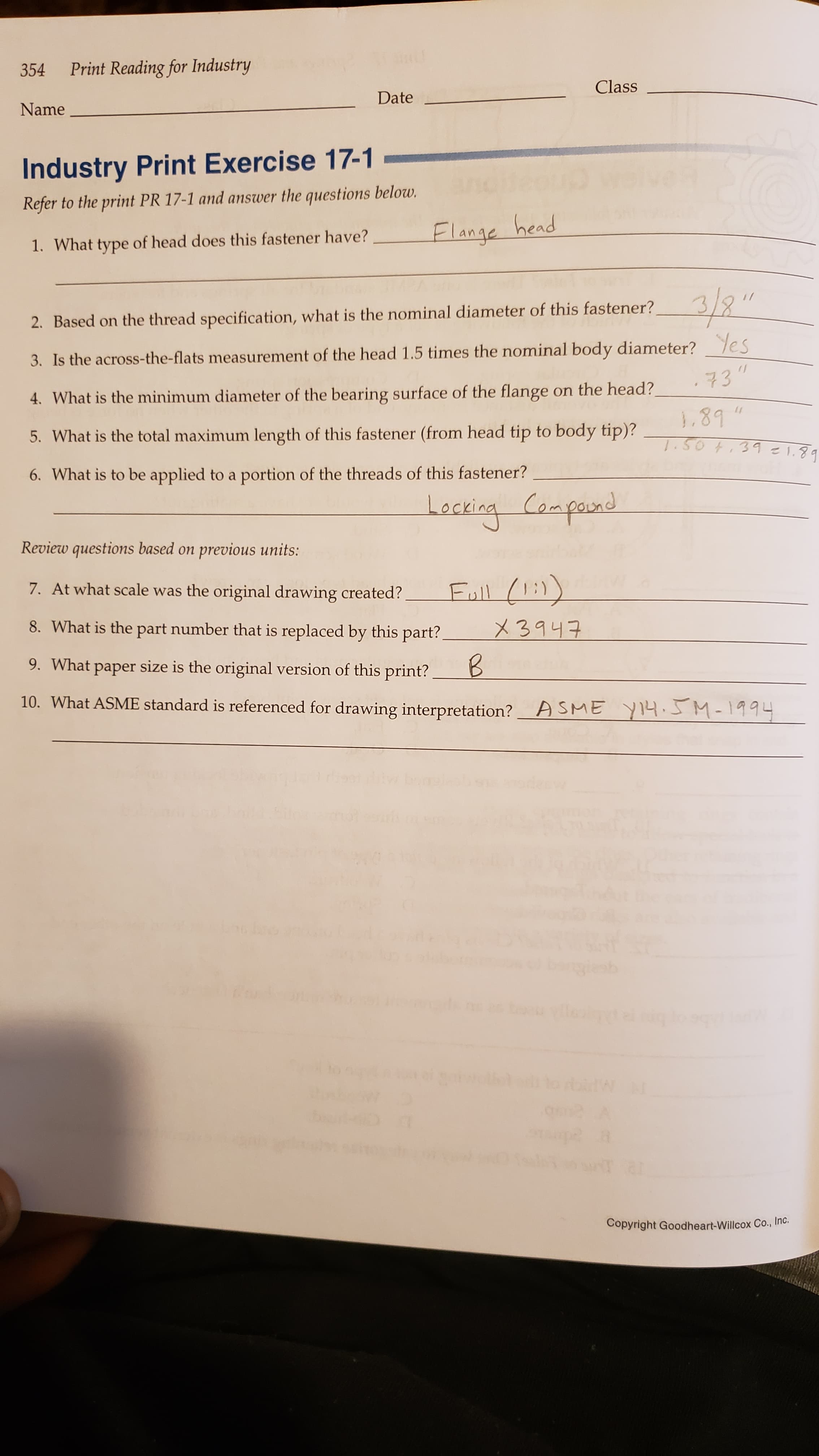

Print Reading for Industry 354 Class Date Name Industry Print Exercise 17-1 Refer to the print PR 17-1 and answer the questions below. Flange head 1. What type of head does this fastener have? 2. Based on the thread specification, what is the nominal diameter of this fastener? 3. Is the across-the-flats measurement of the head 1.5 times the nominal body diameter? es 73" 4. What is the minimum diameter of the bearing surface of the flange on the head? 3.89 5. What is the total maximum length of this fastener (from head tip to body tip)? .SOT.391.8 6. What is to be applied to a portion of the threads of this fastener? Leckina Caapand Review questions based on previous units: Eall 1: 7. At what scale was the original drawing created? 8. What is the part number that is replaced by this part? 3943 9. What paper size is the original version of this print? 10. What ASME standard is referenced for drawing interpretation? A SME YI4M-1994 be u vile LTA pe al Copyright Goodheart-Willcox Co., In 3 Unit 17 Springs and Fasteners in Industrial Prints 12 Print supplied by H 7-1. Hex Flange Screw. ht Goodheart-Willcox Co., Inc. CHANGES TORQUE VALUES BREAKAWAY TORQUE NOTES: PREVAILING ON TORQUE PREVAILING OFF TORQUE REFERENCE IFI-111 2002 48 IN-LBS MAX 60 IN-LBS MIN 36 IN-LBS MIN 2. REFERENCE IFI-125 2002 .25 MIN 1.50 1.46 .81 MAX CHANGES . 39 MAX 3/8-16 UNC- 2A .650 .618 . 30 .15 15 .36 MIN .5625 .5510 LOCK ING COMPOUND 360 AROUND THREADS ø. 73 MIN 1-DEAS DRAWING INTERPRETATION PER ASME Y14.5M-1994 TOLERANCES UNLESS SPECIFIED t.020 t.010 .005 Hydro-Gear 1411 SO. HAMILTON ST. SULLIVAN, IL 61951 PHONE (217) 728-2581 DATE NAME 00 000 DRAWN CHECKED APPR SIZE SCALE NAME SCREW 01/26/04 SAD 0000 ANGLE FORMER PART NO. த X3947 DRAWN IN INCHES HEX FLANGE HEAD 3/8-16 X 1.50 SHEET 1 OF 1 PART NO. 52137 MATERIAL: GRADE 8 н FULL CHG FINISH: PHOSPHATE AND OIL PROJECT REFERENCE: ZT2800

Print Reading for Industry 354 Class Date Name Industry Print Exercise 17-1 Refer to the print PR 17-1 and answer the questions below. Flange head 1. What type of head does this fastener have? 2. Based on the thread specification, what is the nominal diameter of this fastener? 3. Is the across-the-flats measurement of the head 1.5 times the nominal body diameter? es 73" 4. What is the minimum diameter of the bearing surface of the flange on the head? 3.89 5. What is the total maximum length of this fastener (from head tip to body tip)? .SOT.391.8 6. What is to be applied to a portion of the threads of this fastener? Leckina Caapand Review questions based on previous units: Eall 1: 7. At what scale was the original drawing created? 8. What is the part number that is replaced by this part? 3943 9. What paper size is the original version of this print? 10. What ASME standard is referenced for drawing interpretation? A SME YI4M-1994 be u vile LTA pe al Copyright Goodheart-Willcox Co., In 3 Unit 17 Springs and Fasteners in Industrial Prints 12 Print supplied by H 7-1. Hex Flange Screw. ht Goodheart-Willcox Co., Inc. CHANGES TORQUE VALUES BREAKAWAY TORQUE NOTES: PREVAILING ON TORQUE PREVAILING OFF TORQUE REFERENCE IFI-111 2002 48 IN-LBS MAX 60 IN-LBS MIN 36 IN-LBS MIN 2. REFERENCE IFI-125 2002 .25 MIN 1.50 1.46 .81 MAX CHANGES . 39 MAX 3/8-16 UNC- 2A .650 .618 . 30 .15 15 .36 MIN .5625 .5510 LOCK ING COMPOUND 360 AROUND THREADS ø. 73 MIN 1-DEAS DRAWING INTERPRETATION PER ASME Y14.5M-1994 TOLERANCES UNLESS SPECIFIED t.020 t.010 .005 Hydro-Gear 1411 SO. HAMILTON ST. SULLIVAN, IL 61951 PHONE (217) 728-2581 DATE NAME 00 000 DRAWN CHECKED APPR SIZE SCALE NAME SCREW 01/26/04 SAD 0000 ANGLE FORMER PART NO. த X3947 DRAWN IN INCHES HEX FLANGE HEAD 3/8-16 X 1.50 SHEET 1 OF 1 PART NO. 52137 MATERIAL: GRADE 8 н FULL CHG FINISH: PHOSPHATE AND OIL PROJECT REFERENCE: ZT2800

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answers to parts 10, 11, and 12, pertaining to the print provided.

Transcribed Image Text:Print Reading for Industry

354

Class

Date

Name

Industry Print Exercise 17-1

Refer to the print PR 17-1 and answer the questions below.

Flange head

1. What type of head does this fastener have?

2. Based on the thread specification, what is the nominal diameter of this fastener?

3. Is the across-the-flats measurement of the head 1.5 times the nominal body diameter? es

73"

4. What is the minimum diameter of the bearing surface of the flange on the head?

3.89

5. What is the total maximum length of this fastener (from head tip to body tip)?

.SOT.391.8

6. What is to be applied to a portion of the threads of this fastener?

Leckina Caapand

Review questions based on previous units:

Eall 1:

7. At what scale was the original drawing created?

8. What is the part number that is replaced by this part?

3943

9. What paper size is the original version of this print?

10. What ASME standard is referenced for drawing interpretation?

A SME YI4M-1994

be u vile

LTA

pe

al

Copyright Goodheart-Willcox Co., In

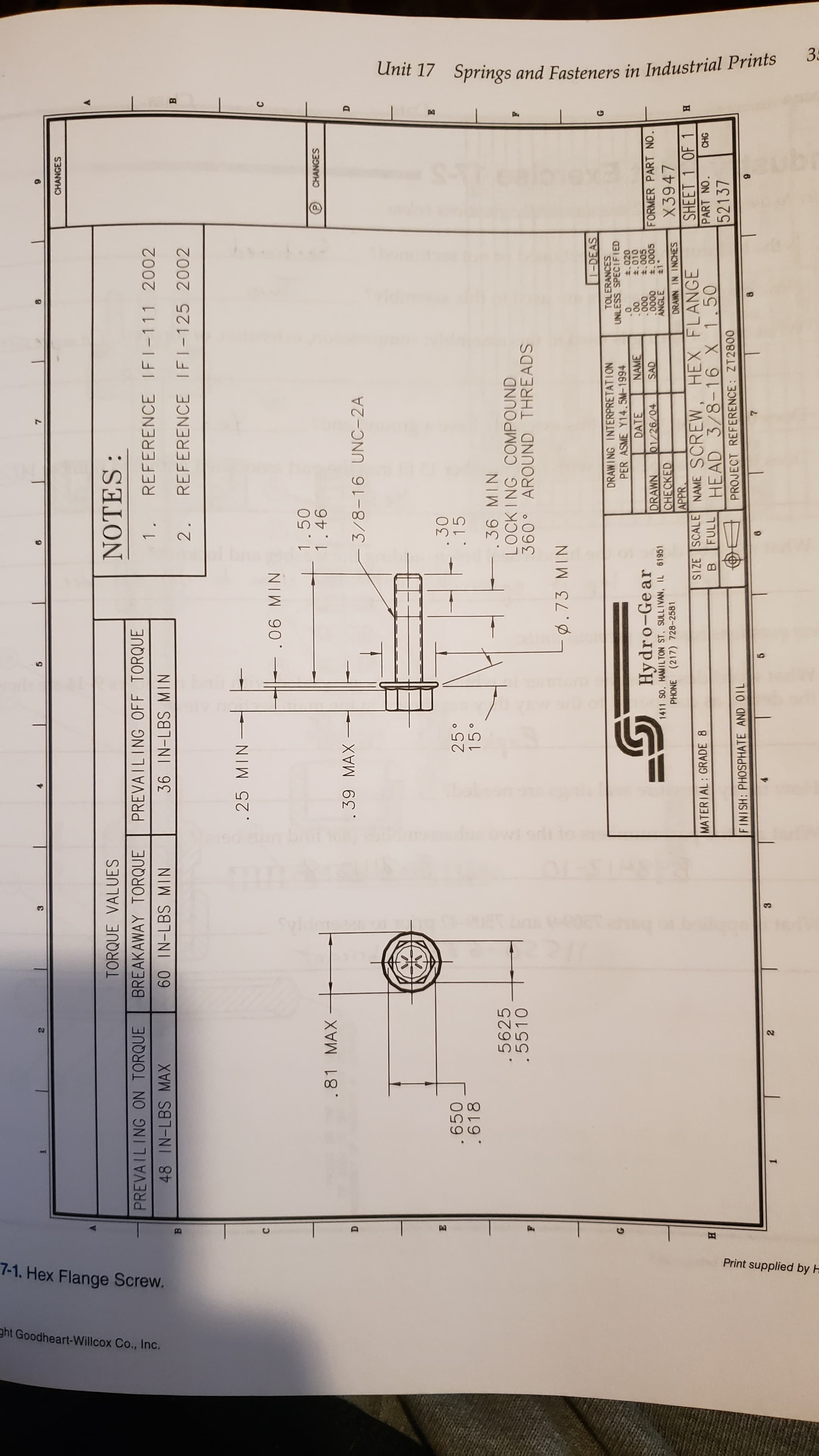

Transcribed Image Text:3

Unit 17

Springs and Fasteners in Industrial Prints

12

Print supplied by H

7-1. Hex Flange Screw.

ht Goodheart-Willcox Co., Inc.

CHANGES

TORQUE VALUES

BREAKAWAY TORQUE

NOTES:

PREVAILING ON TORQUE

PREVAILING OFF TORQUE

REFERENCE IFI-111 2002

48 IN-LBS MAX

60 IN-LBS MIN

36 IN-LBS MIN

2.

REFERENCE IFI-125 2002

.25 MIN

1.50

1.46

.81 MAX

CHANGES

. 39 MAX

3/8-16 UNC- 2A

.650

.618

. 30

.15

15

.36 MIN

.5625

.5510

LOCK ING COMPOUND

360 AROUND THREADS

ø. 73 MIN

1-DEAS

DRAWING INTERPRETATION

PER ASME Y14.5M-1994

TOLERANCES

UNLESS SPECIFIED

t.020

t.010

.005

Hydro-Gear

1411 SO. HAMILTON ST. SULLIVAN, IL 61951

PHONE (217) 728-2581

DATE

NAME

00

000

DRAWN

CHECKED

APPR

SIZE SCALE NAME SCREW

01/26/04

SAD

0000

ANGLE

FORMER PART NO.

த

X3947

DRAWN IN INCHES

HEX FLANGE

HEAD 3/8-16 X 1.50

SHEET 1 OF 1

PART NO.

52137

MATERIAL: GRADE 8

н

FULL

CHG

FINISH: PHOSPHATE AND OIL

PROJECT REFERENCE: ZT2800

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY