Print Reading for Industry Class 334 Date Name Industry Print Exercise 16-1 Refer to the print PR 16-1 and answer the questions below. 1. How many assemblies are described by this one assembly drawing? 2. Each assembly described by this drawing uses one of two subassemblies, either or part number part number 3. What one part number is common to all of the assemblies described by this drawing? 4. How many different BODY options are there with respect to this drawing? 5. How will the date code be applied to the assembly? 6. What is the find number of the part that is adjusted to set the spring compression? 7. What is the basic height of this assembly as shown in the section view? 8. What process is to be performed just prior to assembly? 9. Is the main spring shown as a section? Review questions based on previous units: 10. What paper size is the original version of this print? 11. Who checked this drawing? 12. What does it mean that the .875 HEX dimension value is in parentheses? 13. What is the scale of the views on the original drawing?, 14. In what month was this drawing issued? 15. Are there any cutting-plane lines shown in this drawing? Copyright Goodheart-Willcox Co., 335 Assembly Drawings Unit 16 www Print supplied by RegO Cryo-Flow Product PR 16-1. PRV Blank. Copyright Goodheart-Willcox Co., Inc. NOTES: 1. CAUTION: SPRING MATERIAL MUST BE STAINLESS STEEL. 2. DRAWING SHOWS SPRING GUIDE ASSEMBLY PRV250-4. 3. THIS DISTANCE IS REQUIRED FOR SPRING COMPRESSION, AND SEAT'S COMPRESSION SET REMOVAL. 4. DRAWING SHOWS BODY PRV375-1, WITH WEEP HOLE. 5. CLEAN ITEMS 1-4 PER B-11550-400 COL 1 COL 2 COL 3 COL 4 COL 5 RANGE (PSIG) SPRING GUIDE ASSEMBLY ASSEMBLY SPRING BODY BX250-025 BX250-065 BX250-115 BX250-180 PRV9433F-A 10-39 PRV250-10 PRV375-1 PRV9433F-B 40-89 PRV250-10 PRV375-1 (.875 HEX) PRV9433F-C 90-139 PRV250-10 PRV375-1 140-199 JUST PRIOR TO ASSEMBLY. 6. STORE CLEANED ITEMS IN CLEAN, SEALED CONTAINERS IN THE CLEAN ROOM. PRV9433T-D PRV250-4 PRV375-1 PRV9433T-E PRV9433T-F PRV9433T-G BX250-260 BX250-340 BX250-420 BX250-500 BX250-025 BX250-065 BX250-115 BX250-180 BX250-260 66-00M 200-299 PRV250-4 PRV375-1 300-379 PRV250-4 PRV375- 380-459 PRV250-4 PRV375-1 PRV9433T-H 460-550 PRV250-4 PRV375-1 PRV9433FP-A 10-39 PRV250-10 PRV375P-1 PRV9433FP-B 40-89 PRV250-10 PRV375P-1 PRV9433FP-C 90-139 PRV250-10 PRV375P-1 0 (SEE NOTE 3) PRV9433TP-D 140-199 PRV250-4 PRV375P-1 STAMPING INFORMATION PRV9433TP -E PRV250-4 PRV375P-1 BX250-340 BX250-420 BX250-500 PRESSURE PRV9433TP-F 300-379 PRV250-4 PRV375P-1 (F, T, FP, OR TP)SETTING IN PSI REGO PRV9433 PS C BAR C PRV9433TP-G 380-459 PRV250-4 PRV375P-1 PRV9433TP-H 460-550 PRV250-4 PRV375P-1 DATE CODE EQUIVALENT PRESSURE SETTING IN BAR 1 ADJUSTING SCREW PRV250-3 3 SPRING SEE COL 3 (2.625) 2 SPRING GUIDE ASSEMBLY SEE COL 4 3 BODY SEE COL 5 ITEM QTY. DESCRIPTION NUMBER DRAWN ENGINEER T. TICKLE REGO CRYO-FLOW PRODUCTS J. OLSEN CHECKED APPROVED D. WILLIAMS J. OLSEN BURLINGTON, N.C. 27215 THIS DRAWING IS ECII PROPRIETARY INFORMATION ALL RIGHTS OF DESIGN OR INVENTION ARE RESERVED ORIGINAL DATE PLOT GENERATED: 05/25 08/02 UNLESS OTHERWISE SPECIFIED: t .015 2 PL DEC. .02 3 PL DEC. t 005 REVISIONS TITLE A206, 05/25 ISSUED ANGLES 00 30 PRV BLANK CONCENTRICITY .010 FIM FINISH 125 MAX REMOVE BURRS, BREAK SHARP EDGES R.015 MAX INTERPRET DIMENSIONS& TOLERANCESAW ASME Y14.5M-1994 DRAWING NO. PRVO09433XX-XB SCALE -CHANGES -GAGES (2:1)

Print Reading for Industry Class 334 Date Name Industry Print Exercise 16-1 Refer to the print PR 16-1 and answer the questions below. 1. How many assemblies are described by this one assembly drawing? 2. Each assembly described by this drawing uses one of two subassemblies, either or part number part number 3. What one part number is common to all of the assemblies described by this drawing? 4. How many different BODY options are there with respect to this drawing? 5. How will the date code be applied to the assembly? 6. What is the find number of the part that is adjusted to set the spring compression? 7. What is the basic height of this assembly as shown in the section view? 8. What process is to be performed just prior to assembly? 9. Is the main spring shown as a section? Review questions based on previous units: 10. What paper size is the original version of this print? 11. Who checked this drawing? 12. What does it mean that the .875 HEX dimension value is in parentheses? 13. What is the scale of the views on the original drawing?, 14. In what month was this drawing issued? 15. Are there any cutting-plane lines shown in this drawing? Copyright Goodheart-Willcox Co., 335 Assembly Drawings Unit 16 www Print supplied by RegO Cryo-Flow Product PR 16-1. PRV Blank. Copyright Goodheart-Willcox Co., Inc. NOTES: 1. CAUTION: SPRING MATERIAL MUST BE STAINLESS STEEL. 2. DRAWING SHOWS SPRING GUIDE ASSEMBLY PRV250-4. 3. THIS DISTANCE IS REQUIRED FOR SPRING COMPRESSION, AND SEAT'S COMPRESSION SET REMOVAL. 4. DRAWING SHOWS BODY PRV375-1, WITH WEEP HOLE. 5. CLEAN ITEMS 1-4 PER B-11550-400 COL 1 COL 2 COL 3 COL 4 COL 5 RANGE (PSIG) SPRING GUIDE ASSEMBLY ASSEMBLY SPRING BODY BX250-025 BX250-065 BX250-115 BX250-180 PRV9433F-A 10-39 PRV250-10 PRV375-1 PRV9433F-B 40-89 PRV250-10 PRV375-1 (.875 HEX) PRV9433F-C 90-139 PRV250-10 PRV375-1 140-199 JUST PRIOR TO ASSEMBLY. 6. STORE CLEANED ITEMS IN CLEAN, SEALED CONTAINERS IN THE CLEAN ROOM. PRV9433T-D PRV250-4 PRV375-1 PRV9433T-E PRV9433T-F PRV9433T-G BX250-260 BX250-340 BX250-420 BX250-500 BX250-025 BX250-065 BX250-115 BX250-180 BX250-260 66-00M 200-299 PRV250-4 PRV375-1 300-379 PRV250-4 PRV375- 380-459 PRV250-4 PRV375-1 PRV9433T-H 460-550 PRV250-4 PRV375-1 PRV9433FP-A 10-39 PRV250-10 PRV375P-1 PRV9433FP-B 40-89 PRV250-10 PRV375P-1 PRV9433FP-C 90-139 PRV250-10 PRV375P-1 0 (SEE NOTE 3) PRV9433TP-D 140-199 PRV250-4 PRV375P-1 STAMPING INFORMATION PRV9433TP -E PRV250-4 PRV375P-1 BX250-340 BX250-420 BX250-500 PRESSURE PRV9433TP-F 300-379 PRV250-4 PRV375P-1 (F, T, FP, OR TP)SETTING IN PSI REGO PRV9433 PS C BAR C PRV9433TP-G 380-459 PRV250-4 PRV375P-1 PRV9433TP-H 460-550 PRV250-4 PRV375P-1 DATE CODE EQUIVALENT PRESSURE SETTING IN BAR 1 ADJUSTING SCREW PRV250-3 3 SPRING SEE COL 3 (2.625) 2 SPRING GUIDE ASSEMBLY SEE COL 4 3 BODY SEE COL 5 ITEM QTY. DESCRIPTION NUMBER DRAWN ENGINEER T. TICKLE REGO CRYO-FLOW PRODUCTS J. OLSEN CHECKED APPROVED D. WILLIAMS J. OLSEN BURLINGTON, N.C. 27215 THIS DRAWING IS ECII PROPRIETARY INFORMATION ALL RIGHTS OF DESIGN OR INVENTION ARE RESERVED ORIGINAL DATE PLOT GENERATED: 05/25 08/02 UNLESS OTHERWISE SPECIFIED: t .015 2 PL DEC. .02 3 PL DEC. t 005 REVISIONS TITLE A206, 05/25 ISSUED ANGLES 00 30 PRV BLANK CONCENTRICITY .010 FIM FINISH 125 MAX REMOVE BURRS, BREAK SHARP EDGES R.015 MAX INTERPRET DIMENSIONS& TOLERANCESAW ASME Y14.5M-1994 DRAWING NO. PRVO09433XX-XB SCALE -CHANGES -GAGES (2:1)

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter5: Turning

Section5.4: Manual Lathe Threading

Problem 3RQ: How many classes of fit are there in the Unified National system?

Related questions

Question

I need answers to parts 4, 5, and 6, pertaining to the print provided.

Transcribed Image Text:Print Reading for Industry

Class

334

Date

Name

Industry Print Exercise 16-1

Refer to the print PR 16-1 and answer the questions below.

1. How many assemblies are described by this one assembly drawing?

2. Each assembly described by this drawing uses one of two subassemblies, either

or part number

part number

3. What one part number is common to all of the assemblies described by this drawing?

4. How many different BODY options are there with respect to this drawing?

5. How will the date code be applied to the assembly?

6. What is the find number of the part that is adjusted to set the spring compression?

7. What is the basic height of this assembly as shown in the section view?

8. What process is to be performed just prior to assembly?

9. Is the main spring shown as a section?

Review questions based on previous units:

10. What paper size is the original version of this print?

11. Who checked this drawing?

12. What does it mean that the .875 HEX dimension value is in parentheses?

13. What is the scale of the views on the original drawing?,

14. In what month was this drawing issued?

15. Are there any cutting-plane lines shown in this drawing?

Copyright Goodheart-Willcox Co.,

Transcribed Image Text:335

Assembly Drawings

Unit 16

www

Print supplied by RegO Cryo-Flow Product

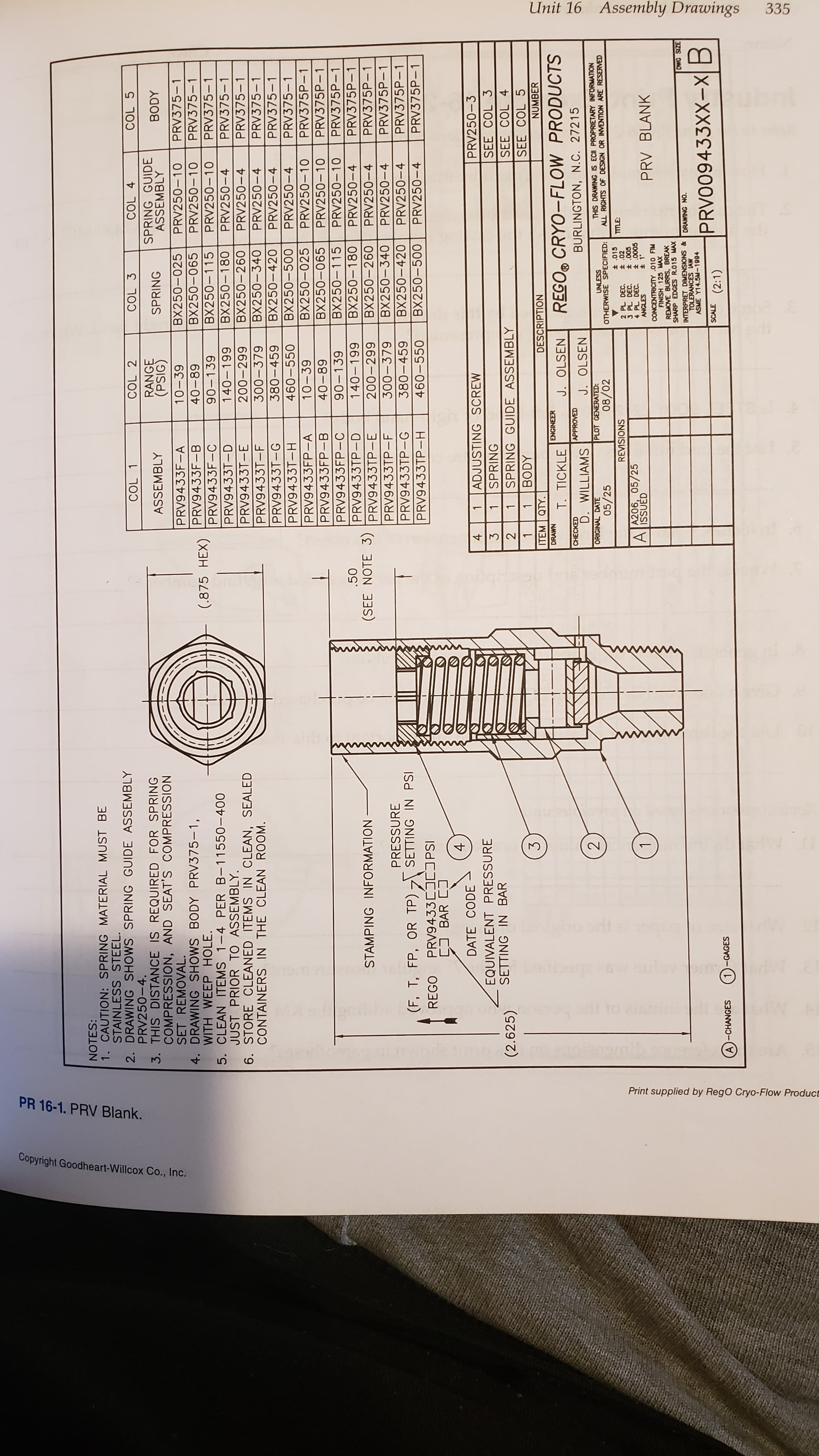

PR 16-1. PRV Blank.

Copyright Goodheart-Willcox Co., Inc.

NOTES:

1. CAUTION: SPRING MATERIAL MUST BE

STAINLESS STEEL.

2. DRAWING SHOWS SPRING GUIDE ASSEMBLY

PRV250-4.

3. THIS DISTANCE IS REQUIRED FOR SPRING

COMPRESSION, AND SEAT'S COMPRESSION

SET REMOVAL.

4. DRAWING SHOWS BODY PRV375-1,

WITH WEEP HOLE.

5. CLEAN ITEMS 1-4 PER B-11550-400

COL 1

COL 2

COL 3

COL 4

COL 5

RANGE

(PSIG)

SPRING GUIDE

ASSEMBLY

ASSEMBLY

SPRING

BODY

BX250-025

BX250-065

BX250-115

BX250-180

PRV9433F-A

10-39

PRV250-10

PRV375-1

PRV9433F-B

40-89

PRV250-10

PRV375-1

(.875 HEX)

PRV9433F-C

90-139

PRV250-10

PRV375-1

140-199

JUST PRIOR TO ASSEMBLY.

6. STORE CLEANED ITEMS IN CLEAN, SEALED

CONTAINERS IN THE CLEAN ROOM.

PRV9433T-D

PRV250-4

PRV375-1

PRV9433T-E

PRV9433T-F

PRV9433T-G

BX250-260

BX250-340

BX250-420

BX250-500

BX250-025

BX250-065

BX250-115

BX250-180

BX250-260

66-00M

200-299

PRV250-4

PRV375-1

300-379

PRV250-4

PRV375-

380-459

PRV250-4

PRV375-1

PRV9433T-H

460-550

PRV250-4

PRV375-1

PRV9433FP-A

10-39

PRV250-10

PRV375P-1

PRV9433FP-B

40-89

PRV250-10

PRV375P-1

PRV9433FP-C

90-139

PRV250-10

PRV375P-1

0

(SEE NOTE 3)

PRV9433TP-D

140-199

PRV250-4

PRV375P-1

STAMPING INFORMATION

PRV9433TP -E

PRV250-4

PRV375P-1

BX250-340

BX250-420

BX250-500

PRESSURE

PRV9433TP-F

300-379

PRV250-4

PRV375P-1

(F, T, FP, OR TP)SETTING IN PSI

REGO PRV9433 PS

C BAR C

PRV9433TP-G

380-459

PRV250-4

PRV375P-1

PRV9433TP-H

460-550

PRV250-4

PRV375P-1

DATE CODE

EQUIVALENT PRESSURE

SETTING IN BAR

1 ADJUSTING SCREW

PRV250-3

3

SPRING

SEE COL 3

(2.625)

2

SPRING GUIDE ASSEMBLY

SEE COL 4

3

BODY

SEE COL 5

ITEM QTY.

DESCRIPTION

NUMBER

DRAWN

ENGINEER

T. TICKLE

REGO CRYO-FLOW PRODUCTS

J. OLSEN

CHECKED

APPROVED

D. WILLIAMS

J. OLSEN

BURLINGTON, N.C. 27215

THIS DRAWING IS ECII PROPRIETARY INFORMATION

ALL RIGHTS OF DESIGN OR INVENTION ARE RESERVED

ORIGINAL DATE

PLOT GENERATED:

05/25

08/02

UNLESS

OTHERWISE SPECIFIED:

t .015

2 PL DEC. .02

3 PL DEC. t 005

REVISIONS

TITLE

A206, 05/25

ISSUED

ANGLES

00 30

PRV BLANK

CONCENTRICITY .010 FIM

FINISH 125 MAX

REMOVE BURRS, BREAK

SHARP EDGES R.015 MAX

INTERPRET DIMENSIONS&

TOLERANCESAW

ASME Y14.5M-1994

DRAWING NO.

PRVO09433XX-XB

SCALE

-CHANGES

-GAGES

(2:1)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning