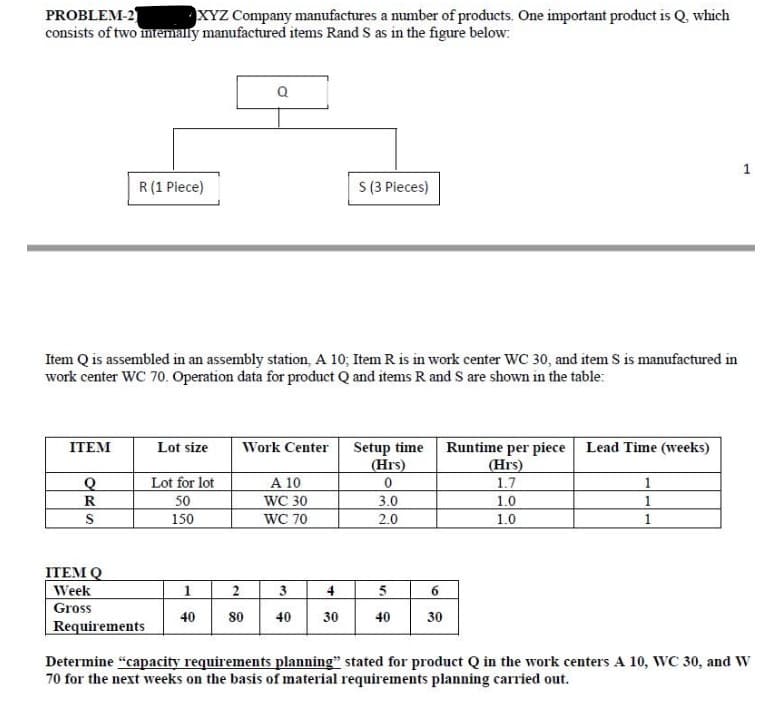

PROBLEM-2 XYZ Company manufactures a number of products. One important product is Q, which consists of two internally manufactured items Rand S as in the figure below: R (1 Piece) ITEM Q R S Item Q is assembled in an assembly station, A 10; Item R is in work center WC 30, and item S is manufactured in work center WC 70. Operation data for product Q and items R and S are shown in the table: ITEM Q Week Gross Requirements Lot size Lot for lot 50 150 Q Work Center 1 2 40 80 A 10 WC 30 WC 70 3 40 S (3 Pieces) 4 30 Setup time (Hrs) 0 3.0 2.0 5 40 6 30 Runtime per piece Lead Time (weeks) (Hrs) 1.7 1.0 1.0 1 1 1 Determine "capacity requirements planning" stated for product Q in the work centers A 10, WC 30, and V 70 for the next weeks on the basis of material requirements planning carried out.

Q: E-commerce Is Growing – Are You Growing with It? By the end of 2019, e-commerce was a fast-growing…

A: Electronic commerce often called e-commerce can be stated as the organizations and people that…

Q: Plantronics managers believe that most people around the world can wear the same type of headset.…

A: Note- Hi! Thank you for the question As per the honour code, We’ll answer the first question since…

Q: An operation has a scrap rate of 15%. As a result, 102 sellable pieces per hour are produced. a.…

A: Scrap rate = 15% Better production = (100%-15%) Better production = 85% or 0.85 Hourly production =…

Q: Calculate the forecast for Week 16 using - a 2-period moving average - a 3-period moving average…

A: Given data is

Q: A company that makes shopping carts for supermarkets and other stores recently purchased some new…

A: Productivity is the measure of output produced per input used. Productivity = output/input

Q: Examine each of the external environmental factors that may be a threat to stakeholder relations.

A: An external environment can be stated as the factors that comprise all the external or outside…

Q: Roger Ginde is developing a program in supply chain management certification for managers. Ginde has…

A: A resource-utilization approach called the Critical path method (CPM) is used to schedule a group of…

Q: QUESTION 4 Mega Inc. manufactures hairdryers for the commercial market. One of the crucial parts…

A: Given, Annual demand, d =60000 units Handling cost, h =RM 0.50 per unit per month = 12×0.50 =$6 per…

Q: Determine each alternative's break-even point in units. At what what volume of output would the two…

A: When the current value of an item equals its acquisition price, such price is known as the breakeven…

Q: summarize the purpose and benefits of customer service.

A: Customer service:- The providing of service to customers before, during, and after the purchase of…

Q: a. plot the data on a graph showing the trend b. determine the equation of the trend line c.…

A: Forecasting is a technique used to predict future outcomes on the basis of past data. In businesses…

Q: 3.8 Given the following data, calculate how many units are available to promise. There are zero…

A: Week 1 2 3 4 5 6 Customer order 21 0 17 8 0 3 Inventory on hand 0 MPS 30 0…

Q: You work for the Brad's Nailer Company which manufactures three types of nailers: a pneumatic model,…

A: From the given information, there are three types of nailers, Pneumatic, ProLine and Cordless.…

Q: A linear programming computer package is needed. Edwards Manufacturing Company purchases two…

A: Decision Variable: Suppose-Xij be the no. of units of component i purchased by the company from…

Q: 1. a.) What is forecasting? b. Explain the importance of forecasting for managers like you? c.) What…

A: Forecasting is simply analyzing and evaluating the past or present data to determine or predict the…

Q: Provide at least five project stakeholders as well as the role they play in the Construction…

A: The word stakeholders is often used to refer to those who care about the success of a project or…

Q: what is a free rider in an economy

A: The free rider issue is an economic notion of a market failure. Public goods generally encounter a…

Q: Level 2: Identifying an Operational Strategy Level 3: Identifying the Critical Success Factors…

A: The ROCKART Model for Business Processes has four stages.

Q: If a linear programming problem's solution is not feasible: it is not fun O all constraints have not…

A: If a linear programming problem’s solution is not feasible, it means a linear program is infeasible.…

Q: "Everyone wants a detailed schedule and product cost breakdown. How can I do that when we are not…

A: In reality, as a project manager, it is critical to create a clear schedule and product cost…

Q: 3.8 Given the following data, calculate how many units are available to promise. There are zero…

A: Period 1 2 3 4 5 6 Order 21 0 17 8 0 3 MPS 30 30 30 ATP (a) (b) Inventory on…

Q: Harlen Industries Limited has a simple forecasting model whose forecast demand has been plotted…

A: In this question, we have the table data for an 8 periods duration, for each period, we have actual…

Q: Is transformational leadership beneficial in all kinds of organizations and industries? If so, why?…

A: Transformational leadership is also known as managerial leadership. This type of leadership is based…

Q: Q-The company has kept at one of its plants 24 months records of the total number of failures…

A: Given data-

Q: Dorian Auto manufactures luxury cars and trucks. The company believes that its most likely customers…

A: By locating the greatest or minimum point of intersection seen between the goal function line and,…

Q: Discuss the issues that can affect the maintenance costs. How would you minimize thei maintenance…

A: Any money spent by a person or a company to maintain their assets in excellent functioning condition…

Q: Q1. Aliya has recently enrolled for a computer software development course and now she will be…

A: Given data is

Q: Warehousing activities play a significant role in an efficient distribution goods to the customer.…

A: Inventory management is described as a means of managing the stock of the business products and…

Q: Calculating outcomes as equally likely would BEST describe: O a Maximax criterion O b. Laplace…

A: As per Bartleby guidelines, we can only solve one question at a time...Kindly upload the other…

Q: Twelve identical products were put on test for 65 days, by which time 9 had failed at 21, 25, 29,…

A: Given data: The total number of days of operation = 21, 25, 29, 33, 38, 43, 49, 56 & 65 Products…

Q: A publisher for a promising new novel figures fixed costs (overhead, advances, promotion, copy…

A: Break even point is the point at which company's production cost and production expenses are equal…

Q: Consider the bill of material for a product, A, and the data given in the table that follows. The…

A: The Gross requirements : For A's = 150 Units in week 5 For B's = 200 Units in week 8 To be…

Q: Why is randomization important in an experiment?

A: Randomization is important because : Randomization, which helps to reduce bias, can increase the…

Q: A bicycle component manufacturer produces hubs for bike wheels. Two processes are possible for…

A: From the above given information, Daily production time for process 1 = 4 hours per day Production…

Q: QUESTION 4 a) Assess and discuss the benefits of in-house vs. contracting out maintenance works in…

A: Note: - Since the exact to be answered is not specified, we will answer the first question(a) here.…

Q: Chiltern Farms “[T]he beautiful valley of Vyeboom nestled between the majestic Franschhoek Mountains…

A: Supply chain and logistics is a popular concept that is an efficient network of people, resources,…

Q: Wheels Distributors sells three types of tires to the commercial market. Type A. Type B and Type…

A: The expected value of perfect information is the price that one would be willing to pay in order to…

Q: fter reviewing the solution to part (c), the bank manager realized that some additional requirements…

A: Objective Functions and Constraints: Based on the given details, the objective…

Q: 1. Write short notes about mission,visions and strategies

A: 1. short notes on mission, visions, and strategies. The word mission is derived from a Latin word…

Q: Monday Tuesday Wednesday Thursday Friday Using this table above, solve for Mean Absolute Deviation…

A: MAD is the average of the absolute deviations calculated of each period. Absoluture error =…

Q: new shopping mall is considering setting up an information desk manned by one employee. Based upon…

A: Given data: Arrival rateλ = 20 per hour Service rate μ =1 question2 minute…

Q: Logistics is ensuring all the material and personnel are in the right place at the right time so…

A: The term logistics can be understood as the management of the flow of goods from the point of…

Q: MI’s Pulse of the Profession Reportin 2016states that Organizations waste $97 million for every $1…

A: Formed in 1969, Project Management Institute (PMI) is not-for-profit professional organization…

Q: The Eagle Mountain Hospital uses disposable surgical packages (Surg Pac) for many of the routine…

A: Instead of employing/using a reorder quantity calculation, multiple firms place orders for items…

Q: You work as a supervisor in a manufacturing firm. The company has implemented a balanced-scorecard…

A: A balanced Scorecard is a management approach used by organizations to monitor the internal…

Q: a. Calculating the order size would minimise the sum of annual ordering and carrying costs? b.…

A: EOQ stands for economic order quantity. It is a company's optimal order quantity that undervalues…

Q: Activity Event Immediate 1 2 3 14 5 |6 17 8 development of a new product in your organization. 19 10…

A: Total expected time = (optimistic time +4*most likely time + pessimistic time)/ 6

Q: Hart Manufacturing makes three products. Each product requires manufacturing operations in three…

A: Objective Functions and Constraints: Based on the given details, the objective…

Q: (d) Identify each of the right-hand-side ranges. (Round your answers to two decimal places. If there…

A: Linear programming is a mathematical technique that is also used in operations management…

Q: Brown's, a local bakery, is worried about increased costs particularly energy. Last year's records…

A: Given: Production Last year = U1 = 1500 Energy required last year = B1 = 3000 BTU Production now =…

Step by step

Solved in 3 steps with 5 images

- Problem 2: Comp-Max Computers assembles computers and computer equipment. It is about to start production of threenew types of computers, called model X, Y, and Z, respectively. Each type will require assembly time, inspection time, and storage space. The availability of each of these resources is limited. Specifically, available assembly time is 400 hours, available inspection time is 300 hours, and available storage space is 500 cubic feet (about 14.2 ms). The amount of each resource required for the different products is reported in the table below. Model X earns a profit of $100 per unit, model Yearns a profit of $125 per unit, and model 2 earns a profit of $200 per unit. Due to some prior agreements with customers, Comp-Max must produce at least 12 model X computers. In addition, management requires that the fraction of total production made up of model 2 computers must not exceed 25%. RESOURCE REQUIREMENTS Assembly time Inspection time Storage space MODEL hrs/unit hrsJunit cu.…Accompany makes two products (1&2) each product requires time on two machines (A&B). specification for each product is as follows. Product1 product2 Processing time on Machine A (hrs/unit) 2 2 Processing time on Machine B (hrs/unit) 1 2 Material and labour cost ( ksh/unit) 14 15 Selling price (ksh/unit) 16 18 Maximum possible sale (units) 130 150 The amount of time available on machine A is 360 hours and on machine B is 260 hours. Formulate the linear programme which, when…8-1 (Production problem) Winkler Furniture manufactures two different types of china cabinets: a French Provincial model and a Danish Modern model. Each cabinet produced must go through three departments: carpentry, painting, and finishing. The table on this page contains all relevant information concerning production times per cabinet produced and production capacities for each operation per day, along with net revenue per unit produced. The firm has a contract with an Indiana distributor to produce a minimum of 300 of each cabinet per week (or 60 cabinets per day). Owner Bob Winkler would like to determine a product mix to maximize his daily revenue. Cabinet Style Carpentry (Hours/Cabinet) Painting (Hours/Cabinet) Finishing (Hours/Cabinet) Net Revenue/Cabinet ($) French Provincial 3 1.5 0.75 28 Danish Modern 2 1 0.75 25 Department Capacity (Hours) 360 200 125 a) Formulate as an LP problem. b) Solve using an LP software program or…

- 8-1 (Production problem) Winkler Furniture manufactures two different types of china cabinets: a French Provincial model and a Danish Modern model. Each cabinet produced must go through three departments: carpentry, painting, and finishing. The table on this page contains all relevant information concerning production times per cabinet produced and production capacities for each operation per day, along with net revenue per unit produced. The firm has a contract with an Indiana distributor to produce a minimum of 300 of each cabinet per week (or 60 cabinets per day). Owner Bob Winkler would like to determine a product mix to maximize his daily revenue. Perform the four steps (i.e., define variables, determine objective function, identify constraints, list the non-negativity statement) and write equations. Use the table in the picture2. As part of a quality improvement initiative, Consolidated Electronics employees complete a three-day training program on teaming and a two-day training program on problem solving. The manager of quality improvement has requested that at least 8 training programs on teaming and at least 10 training programs on problem solving be offered during the next six months. In addition, senior-level management has specified that at least 25 training programs must be offered during this period. Consolidated Electronics uses a consultant to teach the training programs. During the next quarter, the consultant has 84 days of training time available. Each training program on teaming costs $10,000 and each training program on problem solving costs $8000. a. Formulate a linear programming model that can be used to determine the number of training programs on teaming and the number of training programs on problem solving that should be offered in order to minimize total cost. b. Determine the optimal…A car company is planning the introduction of a new electric car. There are two options for production. One is to produce the electric car at the company’s existing plant in Illinois, sharing production with its other products that are currently being produced there. If the sales of the electric car are moderate, this will work out well as there is significant capacity to produce all of the products there. However, if sales of the electric car are strong, this option would necessitate Adding a 3rd shift, which would lead to significantly higher costs. Another option is to build a new plant in Ohio. The new plant would have sufficient capacity to meet whatever level of demand for the new car. However, if sales of the new car not strong, the plant would be underutilized and less efficient. Since this is a new product, sales are hard to predict. The forecast indicates there is a 60% chance of strong sales (annual sales of 100,000), and 40% chance of moderate sales (annual sales of…

- Mr Sng is a retiree in his late sixties. He has $100,000 to invest. He has no regular source of income and no other assets. He is evaluating between 3 different lump-sum financial products shown in Table 3. All products require a minimum investment sum of $100,000. Monetary returns represent the net gain after one year of investing in the product. For example, if Mr Sng chose to invest in Product B, he may lose $5,000 after one year if the GDP growth is negative. He will earn $8,000 if the GDP growth exceeds 2% at the end of the year. If you were in the shoes of Mr Sng, how would you select the appropriate investment product for a time horizon of one year? (i) Use the Optimistic, Conservative and Regrets payoff analysis approaches. State which product(s) Mr Sng should invest in and what monetary return he can expect from each approach (ii) As you have only enough funds for one product, identify the most appropriate investment product. [Hint: Be sure to consider the…Gerald Glynn manages the Michaels Distribution Center. After careful examination of his database information, he has determined the daily requirements for part-time loading dock personnel. The distribution center operates 7 days a week, and the daily part-time staffing requirements are: LOADING... Day M T W Th F S Su Requirements 6 3 5 3 7 2 3 Find the minimum number of workers Glynn must hire. Prepare a workforce schedule for these individuals so that each will have 2 consecutive days off per week and all staffing requirements will be satisfied. Give preference to the S-Su pair in case of a tie. (Note: If there is a tie that cannot be broken by following the preference to the S-Su pair, choose the pair closest to the beginning of the considered week.) The minimum number of workers is 77 workers. (Enter…Gerald Glynn manages the Michaels Distribution Center. After careful examination of his database information, he has determined the daily requirements for part-time loading dock personnel. The distribution center operates 7 days a week, and the daily part-time staffing requirements are: LOADING... Day M T W Th F S Su Requirements 6 3 5 3 7 2 3 Find the minimum number of workers Glynn must hire. Prepare a workforce schedule for these individuals so that each will have 2 consecutive days off per week and all staffing requirements will be satisfied. Give preference to the S-Su pair in case of a tie. (Note: If there is a tie that cannot be broken by following the preference to the S-Su pair, choose the pair closest to the beginning of the considered week.) The minimum number of workers is nothing workers.…

- Gerald Glynn manages the Michaels Distribution Center. After careful examination of his database information, he has determined the daily requirements for part-time loading dock personnel. The distribution center operates 7 days a week, and the daily part-time staffing requirements are: LOADING... Day M T W Th F S Su Requirements 6 3 5 3 7 2 3 Find the minimum number of workers Glynn must hire. Prepare a workforce schedule for these individuals so that each will have 2 consecutive days off per week and all staffing requirements will be satisfied. Give preference to the S-Su pair in case of a tie. (Note: If there is a tie that cannot be broken by following the preference to the S-Su pair, choose the pair closest to the beginning of the considered week.) The minimum number of workers is 7 workers. (Enter your…Gerald Glynn manages the Michaels Distribution Center. After careful examination of his database information, he has determined the daily requirements for part-time loading dock personnel. The distribution center operates 7 days a week, and the daily part-time staffing requirements are LOADING... Day M T W Th F S Su Requirements 7 5 4 2 5 2 5 Find the minimum number of workers Glynn must hire. Prepare a workforce schedule for these individuals so that each will have 2 consecutive days off per week and all staffing requirements will be satisfied. Give preference to the S-Su pair in case of a tie. (Note: If there is a tie that cannot be broken by following the preference to the S-Su pair, choose the pair closest to the beginning of the considered week.) Part 2 The minimum number of workers is enter your response…Gerald Glynn manages the Michaels Distribution Center. After careful examination of his database information, he has determined the daily requirements for part-time loading dock personnel. The distribution center operates 7 days a week, and the daily part-time staffing requirements are LOADING... Day M T W Th F S Su Requirements 7 4 4 4 6 2 2 Find the minimum number of workers Glynn must hire. Prepare a workforce schedule for these individuals so that each will have 2 consecutive days off per week and all staffing requirements will be satisfied. Give preference to the S-Su pair in case of a tie. (Note: If there is a tie that cannot be broken by following the preference to the S-Su pair, choose the pair closest to the beginning of the considered week.) The minimum number of workers is 77 workers. (Enter your…