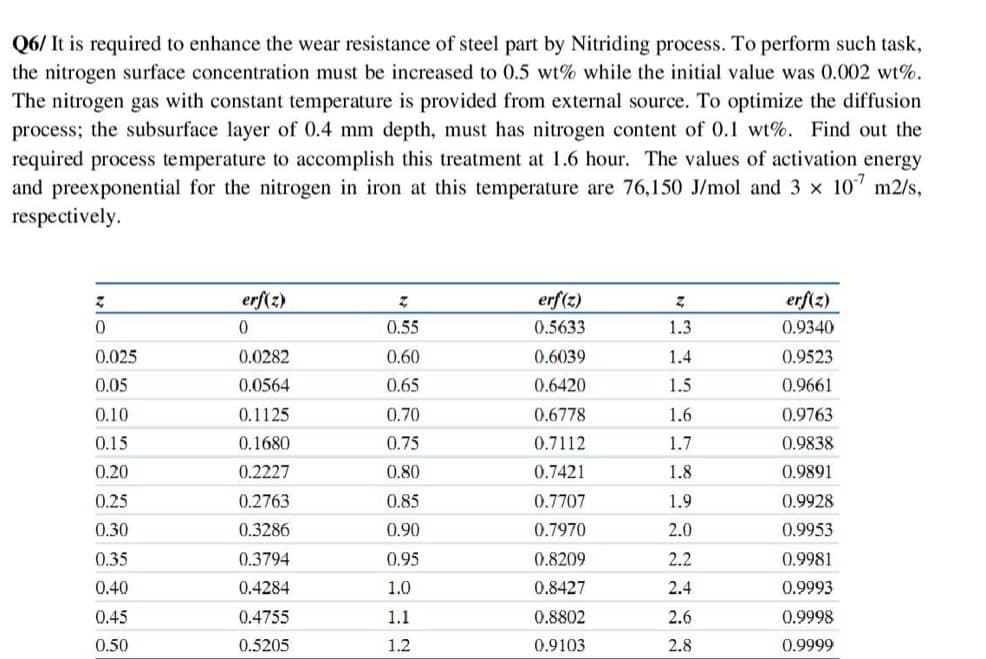

Q6/ It is required to enhance the wear resistance of steel part by Nitriding process. To perform such task, the nitrogen surface concentration must be increased to 0.5 wt% while the initial value was 0.002 wt%. The nitrogen gas with constant temperature is provided from external source. To optimize the diffusion process; the subsurface layer of 0.4 mm depth, must has nitrogen content of 0.1 wt%. Find out the required process temperature to accomplish this treatment at 1.6 hour. The values of activation energy and preexponential for the nitrogen in iron at this temperature are 76,150 J/mol and 3 x 107 m2/s, respectively.

Q6/ It is required to enhance the wear resistance of steel part by Nitriding process. To perform such task, the nitrogen surface concentration must be increased to 0.5 wt% while the initial value was 0.002 wt%. The nitrogen gas with constant temperature is provided from external source. To optimize the diffusion process; the subsurface layer of 0.4 mm depth, must has nitrogen content of 0.1 wt%. Find out the required process temperature to accomplish this treatment at 1.6 hour. The values of activation energy and preexponential for the nitrogen in iron at this temperature are 76,150 J/mol and 3 x 107 m2/s, respectively.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter5: Analysis Of Convection Heat Transfer

Section: Chapter Questions

Problem 5.46P

Related questions

Question

Transcribed Image Text:Q6/ It is required to enhance the wear resistance of steel part by Nitriding process. To perform such task,

the nitrogen surface concentration must be increased to 0.5 wt% while the initial value was 0.002 wt%.

The nitrogen gas with constant temperature is provided from external source. To optimize the diffusion

process; the subsurface layer of 0.4 mm depth, must has nitrogen content of 0.1 wt%. Find out the

required process temperature to accomplish this treatment at 1.6 hour. The values of activation energy

and preexponential for the nitrogen in iron at this temperature are 76,150 J/mol and 3 x 107 m2/s,

respectively.

erf(z)

erf(z)

erf(z)

0.55

0.5633

1.3

0.9340

0.025

0.0282

0.60

0.6039

1.4

0.9523

0.05

0.0564

0.65

0.6420

1.5

0.9661

0.10

0.1125

0.70

0.6778

1.6

0.9763

0.15

0.1680

0.75

0.7112

1.7

0.9838

0.20

0.2227

0.80

0.7421

1.8

0.9891

0.25

0.2763

0.85

0.7707

1.9

0.9928

0.30

0.3286

0.90

0.7970

2.0

0.9953

0.35

0.3794

0.95

0.8209

2.2

0.9981

0.40

0.4284

1.0

0.8427

2.4

0.9993

0.45

0.4755

1.1

0.8802

2.6

0.9998

0.50

0.5205

1.2

0.9103

2.8

0.9999

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning