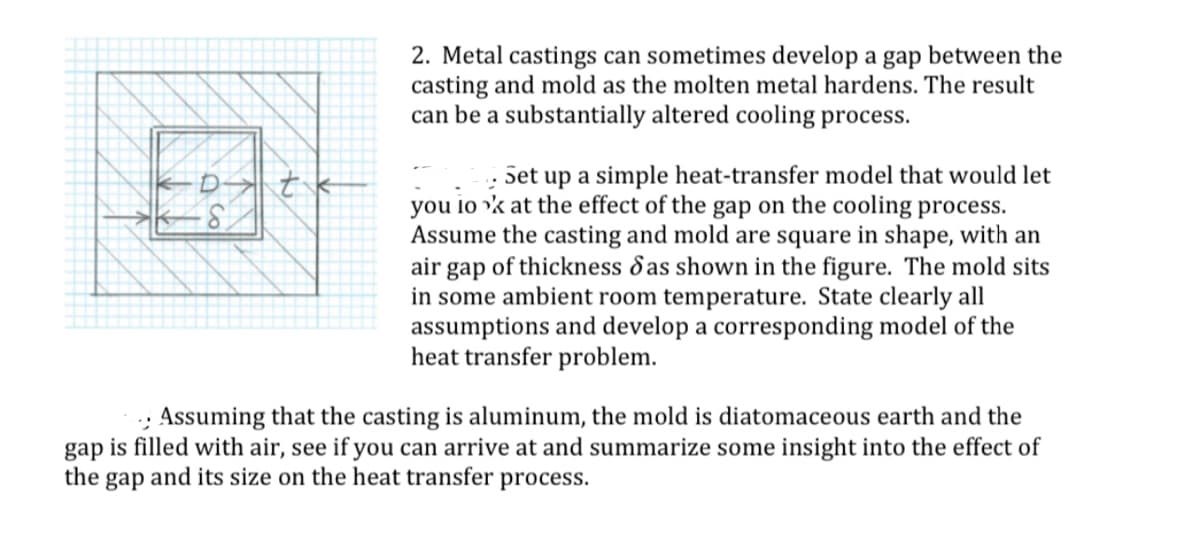

-S tk 2. Metal castings can sometimes develop a gap between the casting and mold as the molten metal hardens. The result can be a substantially altered cooling process. Set up a simple heat-transfer model that would let you look at the effect of the gap on the cooling process. Assume the casting and mold are square in shape, with an air gap of thickness das shown in the figure. The mold sits in some ambient room temperature. State clearly all assumptions and develop a corresponding model of the heat transfer problem. 9 Assuming that the casting is aluminum, the mold is diatomaceous earth and the gap is filled with air, see if you can arrive at and summarize some insight into the effect of the gap and its size on the heat transfer process.

-S tk 2. Metal castings can sometimes develop a gap between the casting and mold as the molten metal hardens. The result can be a substantially altered cooling process. Set up a simple heat-transfer model that would let you look at the effect of the gap on the cooling process. Assume the casting and mold are square in shape, with an air gap of thickness das shown in the figure. The mold sits in some ambient room temperature. State clearly all assumptions and develop a corresponding model of the heat transfer problem. 9 Assuming that the casting is aluminum, the mold is diatomaceous earth and the gap is filled with air, see if you can arrive at and summarize some insight into the effect of the gap and its size on the heat transfer process.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter8: Natural Convection

Section: Chapter Questions

Problem 8.9P

Related questions

Question

Transcribed Image Text:36

-S

42

2. Metal castings can sometimes develop a gap between the

casting and mold as the molten metal hardens. The result

can be a substantially altered cooling process.

Set up a simple heat-transfer model that would let

you look at the effect of the gap on the cooling process.

Assume the casting and mold are square in shape, with an

air gap of thickness das shown in the figure. The mold sits

in some ambient room temperature. State clearly all

assumptions and develop a corresponding model of the

heat transfer problem.

Assuming that the casting is aluminum, the mold is diatomaceous earth and the

gap is filled with air, see if you can arrive at and summarize some insight into the effect of

the

gap and its size on the heat transfer process.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning