Setting Standards, Materials and Labor Variances Tom Belford and Tony Sorrentino own a small business devoted to kitchen and bath granite installations. Recently, building contractors have insisted on up-front bid prices for a house rather than the cost-plus system that Tom and Tony had been using. They worry because natural flaws in the granite make it impossible to tell in advance exactly how much granite will b used on a particular job. In addition, granite can be easily broken, meaning that Tom or Tony could ruin a slab and would need to start over with a new one. Sometimes the improperly cu pieces could be used for smaller installations, sometimes not. All their accounting is done by a local certified public accounting firm headed by Charlene Davenport. Charlene listened to their concerns and suggested that it might be time to implement tighter controls by setting up a standard costing system. Charlene reviewed the invoices pertaining to a number of Tom and Tony's previous jobs to determine the average amount of granite and glue needed per square foot. She then updated prices on both materials to reflect current conditions. The standards she developed for one square foot of counter installed were as follows: Granite, per square foot $50.00 Glue (10 oz. @ $0.15) 1.50 Direct labor hours: Cutting labor (0.10 hr. @ $15) 1.50 Installation labor (0.25 hr. @ $25) 6.25 These standards assumed that one seamless counter requires one sink cut (the space into which the sink will fit) as well as cutting the counter to fit the space available. Charlene tracked the actual costs incurred by Tom and Tony for granite installation for the next 6 months. She found that they completed 50 jobs with an average of 32 square feet of granite installed in each one. The following information on actual amounts used and cost was gathered: Granite purchased and used (1,640 sq. ft.) $82,048 Glue purchased and used (16,000 oz.) $2,560 Actual hours cutting labor 190 Actual hours installation labor 450 The actual wage rate for cutting and installation labor remained unchanged from the standard rate.

Setting Standards, Materials and Labor Variances Tom Belford and Tony Sorrentino own a small business devoted to kitchen and bath granite installations. Recently, building contractors have insisted on up-front bid prices for a house rather than the cost-plus system that Tom and Tony had been using. They worry because natural flaws in the granite make it impossible to tell in advance exactly how much granite will b used on a particular job. In addition, granite can be easily broken, meaning that Tom or Tony could ruin a slab and would need to start over with a new one. Sometimes the improperly cu pieces could be used for smaller installations, sometimes not. All their accounting is done by a local certified public accounting firm headed by Charlene Davenport. Charlene listened to their concerns and suggested that it might be time to implement tighter controls by setting up a standard costing system. Charlene reviewed the invoices pertaining to a number of Tom and Tony's previous jobs to determine the average amount of granite and glue needed per square foot. She then updated prices on both materials to reflect current conditions. The standards she developed for one square foot of counter installed were as follows: Granite, per square foot $50.00 Glue (10 oz. @ $0.15) 1.50 Direct labor hours: Cutting labor (0.10 hr. @ $15) 1.50 Installation labor (0.25 hr. @ $25) 6.25 These standards assumed that one seamless counter requires one sink cut (the space into which the sink will fit) as well as cutting the counter to fit the space available. Charlene tracked the actual costs incurred by Tom and Tony for granite installation for the next 6 months. She found that they completed 50 jobs with an average of 32 square feet of granite installed in each one. The following information on actual amounts used and cost was gathered: Granite purchased and used (1,640 sq. ft.) $82,048 Glue purchased and used (16,000 oz.) $2,560 Actual hours cutting labor 190 Actual hours installation labor 450 The actual wage rate for cutting and installation labor remained unchanged from the standard rate.

Principles of Cost Accounting

17th Edition

ISBN:9781305087408

Author:Edward J. Vanderbeck, Maria R. Mitchell

Publisher:Edward J. Vanderbeck, Maria R. Mitchell

Chapter8: Standard Cost Accounting—materials, Labor, And Factory Overhead

Section: Chapter Questions

Problem 1P: Materials and labor variances Branca Inspections Inc. specializes in determining whether a building...

Related questions

Concept explainers

Variance Analysis

In layman's terms, variance analysis is an analysis of a difference between planned and actual behavior. Variance analysis is mainly used by the companies to maintain a control over a business. After analyzing differences, companies find the reasons for the variance so that the necessary steps should be taken to correct that variance.

Standard Costing

The standard cost system is the expected cost per unit product manufactured and it helps in estimating the deviations and controlling them as well as fixing the selling price of the product. For example, it helps to plan the cost for the coming year on the various expenses.

Topic Video

Question

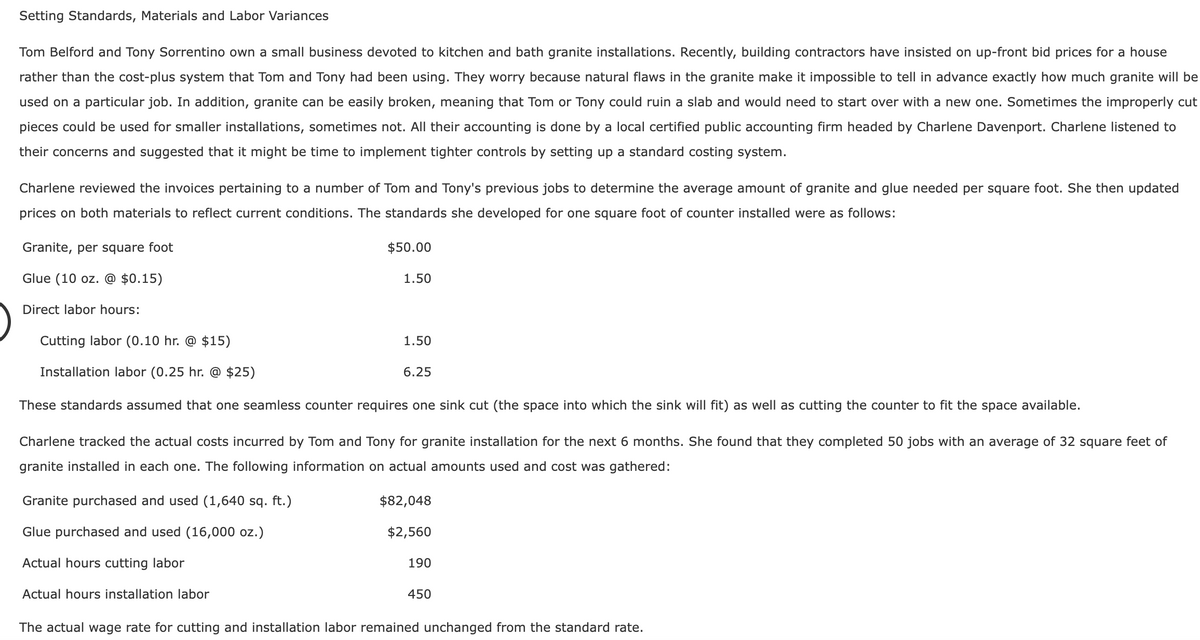

Transcribed Image Text:Setting Standards, Materials and Labor Variances

Tom Belford and Tony Sorrentino own a small business devoted to kitchen and bath granite installations. Recently, building contractors have insisted on up-front bid prices for a house

rather than the cost-plus system that Tom and Tony had been using. They worry because natural flaws in the granite make it impossible to tell in advance exactly how much granite will be

used on a particular job. In addition, granite can be easily broken, meaning that Tom or Tony could ruin a slab and would need to start over with a new one. Sometimes the improperly cut

pieces could be used for smaller installations, sometimes not. All their accounting is done by a local certified public accounting firm headed by Charlene Davenport. Charlene listened to

their concerns and suggested that it might be time to implement tighter controls by setting up a standard costing system.

Charlene reviewed the invoices pertaining to a number of Tom and Tony's previous jobs to determine the average amount of granite and glue needed per square foot. She then updated

prices on both materials to reflect current conditions. The standards she developed for one square foot of counter installed were as follows:

Granite, per square foot

$50.00

Glue (10 oz. @ $0.15)

1.50

Direct labor hours:

Cutting labor (0.10 hr. @ $15)

1.50

Installation labor (0.25 hr. @ $25)

6.25

These standards assumed that one seamless counter requires one sink cut (the space into which the sink will fit) as well as cutting the counter to fit the space available.

Charlene tracked the actual costs incurred by Tom and Tony for granite installation for the next 6 months. She found that they completed 50 jobs with an average of 32 square feet of

granite installed in each one. The following information on actual amounts used and cost was gathered:

Granite purchased and used (1,640 sq. ft.)

$82,048

Glue purchased and used (16,000 oz.)

$2,560

Actual hours cutting labor

190

Actual hours installation labor

450

The actual wage rate for cutting and installation labor remained unchanged from the standard rate.

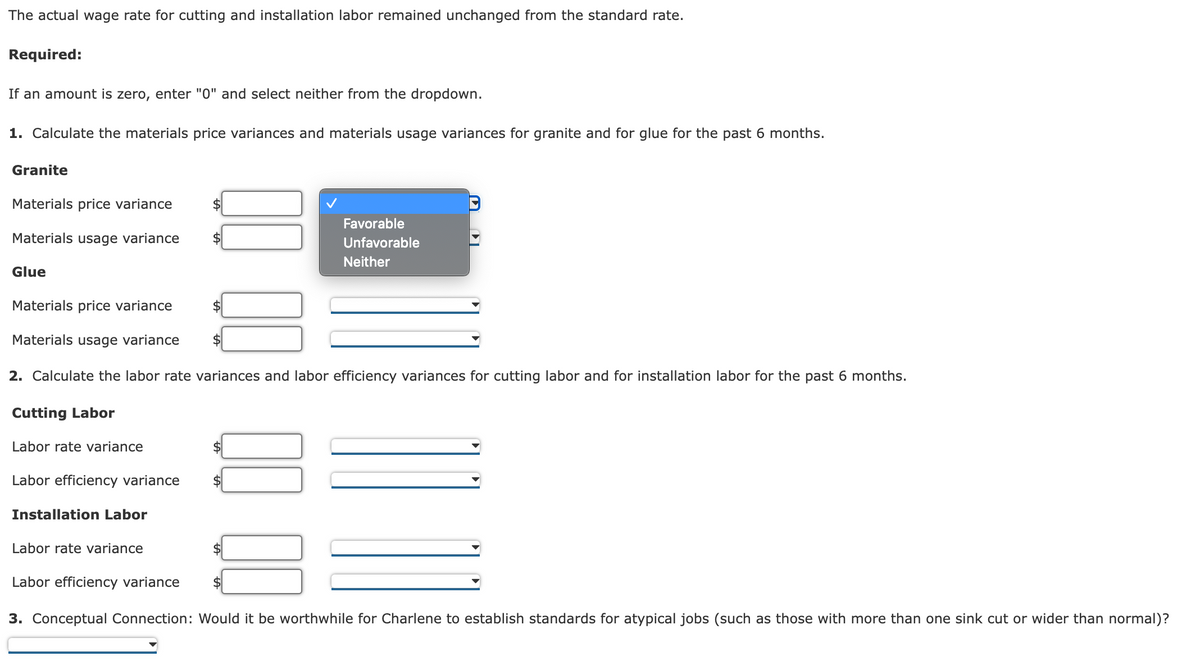

Transcribed Image Text:The actual wage rate for cutting and installation labor remained unchanged from the standard rate.

Required:

If an amount is zero, enter "0" and select neither from the dropdown.

1. Calculate the materials price variances and materials usage variances for granite and for glue for the past 6 months.

Granite

Materials price variance

Favorable

Materials usage variance

$

Unfavorable

Neither

Glue

Materials price variance

Materials usage variance

2. Calculate the labor rate variances and labor efficiency variances for cutting labor and for installation labor for the past 6 months.

Cutting Labor

Labor rate variance

Labor efficiency variance

Installation Labor

Labor rate variance

Labor efficiency variance

2$

3. Conceptual Connection: Would it be worthwhile for Charlene to establish standards for atypical jobs (such as those with more than one sink cut or wider than normal)?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College