SLOS to be assessed: SLO1: Interpret, generate, and practice practical application of graphical and/or algebraic relationships between material structure, composition, properties, and process variables such as stress-strain graphs and phase diagrams. Complete the following hands-on activity involving the construction of the traditional unit cells of the simple cubic, body centered cubic, and face centered cubic Bravais lattice types. 1) Please create models of simple cubic, FCC, and BCC crystal structures using a common uniform spherical objects that can be easily cut such as styrofoam balls (available from craft stores such as Michaels or Hobby Lobby or even round fruit. You can use toothpicks or low temperature hot glue to hold the parts together. For each structure (simple cubic, body centered cubic, or face-centered cubic), include a picture of the dismantled unit cell to demonstrate the number of atoms/unit cell and a picture of your unit cell. The corners of all the unit cells should consist of 1/8 spheres. 2) Verify the relationships between the lattice parameter and atomic radii shown in the lecture slides for each unit cell using the table below. Write a conclusion based on your results.

SLOS to be assessed: SLO1: Interpret, generate, and practice practical application of graphical and/or algebraic relationships between material structure, composition, properties, and process variables such as stress-strain graphs and phase diagrams. Complete the following hands-on activity involving the construction of the traditional unit cells of the simple cubic, body centered cubic, and face centered cubic Bravais lattice types. 1) Please create models of simple cubic, FCC, and BCC crystal structures using a common uniform spherical objects that can be easily cut such as styrofoam balls (available from craft stores such as Michaels or Hobby Lobby or even round fruit. You can use toothpicks or low temperature hot glue to hold the parts together. For each structure (simple cubic, body centered cubic, or face-centered cubic), include a picture of the dismantled unit cell to demonstrate the number of atoms/unit cell and a picture of your unit cell. The corners of all the unit cells should consist of 1/8 spheres. 2) Verify the relationships between the lattice parameter and atomic radii shown in the lecture slides for each unit cell using the table below. Write a conclusion based on your results.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

The project has already been completed, just go through it and confirm if the measurements and picture provided fits the description and specified measurements, PLEASE DRAW THE STRUCTURES PER SPECIFICATIONS BOTH DISMANTELED AND CONSTRUCTED!!!

Transcribed Image Text:Materials and Procedure:

1. Utilize consistent spherical items, such as styrofoam balls, to represent atoms.

2. Section the balls into the required segments to represent atom placements in each crystal

structure, ensuring corners of each unit cell are made from 1/8th of these spheres.

3. Assemble models for each unit cell type: simple cubic (SC), body-centered cubic (BCC), and

face-centered cubic (FCC).

4. Take photos of both the fully assembled unit cells and their disassembled states to display the

number of atoms per unit cell.

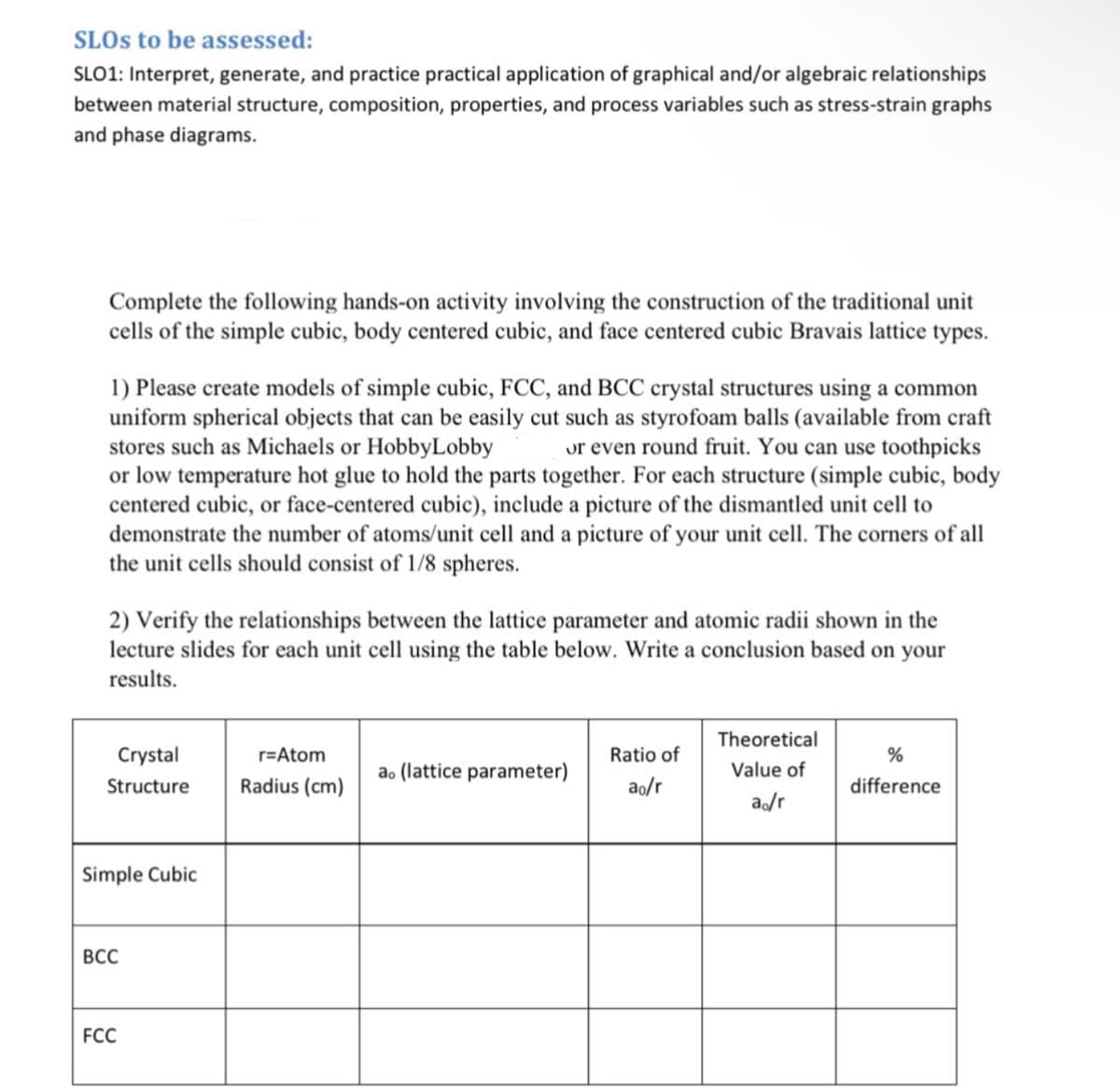

Validation of Theoretical Ratios:

1. For SC, the lattice parameter a0 is twice the atomic radius r, making the ratio a0/r equal to 2.

2. In BCC, the lattice parameter a0 relates to the atomic radius r by a0 = 4r/√3, resulting in a

ratio of a0/r approximately 2.309.

3. For FCC, the lattice parameter a0 is 2√2 times r, leading to a ratio of a0/r of about 2.828.

Results

The table below shows the hypothetical measurements and the calculated ratios

for each crystal structure type:

Crystal Structurer (Atom Radius cm) ao (Lattice parameter) Ratio of 49 Theoretical Value of 49% difference

Simple Cubic

0.1

2

0

BCC

0.1

2.31

0.04

FCC

0.1

2.83

0.07

0.2

0.231

0.283

2.309

2√2 2.828

Transcribed Image Text:SLOS to be assessed:

SLO1: Interpret, generate, and practice practical application of graphical and/or algebraic relationships

between material structure, composition, properties, and process variables such as stress-strain graphs

and phase diagrams.

Complete the following hands-on activity involving the construction of the traditional unit

cells of the simple cubic, body centered cubic, and face centered cubic Bravais lattice types.

1) Please create models of simple cubic, FCC, and BCC crystal structures using a common

uniform spherical objects that can be easily cut such as styrofoam balls (available from craft

stores such as Michaels or Hobby Lobby or even round fruit. You can use toothpicks

or low temperature hot glue to hold the parts together. For each structure (simple cubic, body

centered cubic, or face-centered cubic), include a picture of the dismantled unit cell to

demonstrate the number of atoms/unit cell and a picture of your unit cell. The corners of all

the unit cells should consist of 1/8 spheres.

2) Verify the relationships between the lattice parameter and atomic radii shown in the

lecture slides for each unit cell using the table below. Write a conclusion based on your

results.

Crystal

Structure

Simple Cubic

BCC

FCC

r=Atom

Radius (cm)

ao (lattice parameter)

Ratio of

ao/r

Theoretical

Value of

a./r

%

difference

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY