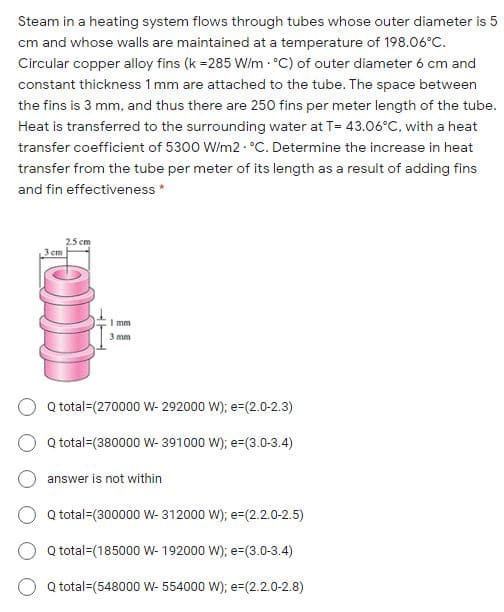

Steam in a heating system flows through tubes whose outer diameter is 5 cm and whose walls are maintained at a temperature of 198.06°C. Circular copper alloy fins (k =285 W/m · °C) of outer diameter 6 cm and constant thickness 1 mm are attached to the tube. The space between the fins is 3 mm, and thus there are 250 fins per meter length of the tube. Heat is transferred to the surrounding water at T= 43.06°C, with a heat transfer coefficient of 5300 W/m2 · °C. Determine the increase in heat transfer from the tube per meter of its length as a result of adding fins and fin effectiveness

Steam in a heating system flows through tubes whose outer diameter is 5 cm and whose walls are maintained at a temperature of 198.06°C. Circular copper alloy fins (k =285 W/m · °C) of outer diameter 6 cm and constant thickness 1 mm are attached to the tube. The space between the fins is 3 mm, and thus there are 250 fins per meter length of the tube. Heat is transferred to the surrounding water at T= 43.06°C, with a heat transfer coefficient of 5300 W/m2 · °C. Determine the increase in heat transfer from the tube per meter of its length as a result of adding fins and fin effectiveness

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter7: Forced Convection Inside Tubes And Ducts

Section: Chapter Questions

Problem 7.17P: Determine the rate of heat transfer per meter length to a light oil flowing through a 2.5-cm-ID,...

Related questions

Question

Steam in a heating system flows through tubes whose outer diameter is 5 cm and whose walls are maintained at a temperature of 198.06°C. Circular copper alloy fins (k =285 W/m · °C) of outer diameter 6 cm and constant thickness 1 mm are attached to the tube. The space between the fins is 3 mm, and thus there are 250 fins per meter length of the tube. Heat is transferred to the surrounding water at T= 43.06°C, with a heat transfer coefficient of 5300 W/m2 · °C. Determine the increase in heat transfer from the tube per meter of its length as a result of adding fins and fin effectiveness

Transcribed Image Text:Steam in a heating system flows through tubes whose outer diameter is 5

cm and whose walls are maintained at a temperature of 198.06°C.

Circular copper alloy fins (k =285 W/m C) of outer diameter 6 cm and

constant thickness 1 mm are attached to the tube. The space between

the fins is 3 mm, and thus there are 250 fins per meter length of the tube.

Heat is transferred to the surrounding water at T= 43.06°C, with a heat

transfer coefficient of 5300 W/m2 - °C. Determine the increase in heat

transfer from the tube per meter of its length as a result of adding fins

and fin effectiveness*

25 cm

3 cm

Imm

3 mm

Q total=(270000 W- 292000 W); e=(2.0-2.3)

Q total=(380000 W- 391000 W); e=(3.0-3.4)

answer is not within

Q total=(300000 W- 312000 W); e=(2.2.0-2.5)

Q total=(185000 W- 192000 W); e=(3.0-3.4)

Q total=(548000 W- 554000 W); e=(2.2.0-2.8)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning