The beam shown will be constructed from a standard steel W-shape using an allowable bending stress of 40.4 ksi. Assume P = 51 kips, L1=6.6 ft, and L2=19.8 ft. (a) Determine the minimum section modulus required for this beam. (b) From the table below, select the lightest W shape that can be used for this beam. (c) What is the total weight of the steel beam itself (i.e., not including the loads that

The beam shown will be constructed from a standard steel W-shape using an allowable bending stress of 40.4 ksi. Assume P = 51 kips, L1=6.6 ft, and L2=19.8 ft. (a) Determine the minimum section modulus required for this beam. (b) From the table below, select the lightest W shape that can be used for this beam. (c) What is the total weight of the steel beam itself (i.e., not including the loads that

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter5: Stresses In Beams (basic Topics)

Section: Chapter Questions

Problem 5.6.13P: A two-axle carriage that is part of an over head traveling crane in a testing laboratory moves...

Related questions

Question

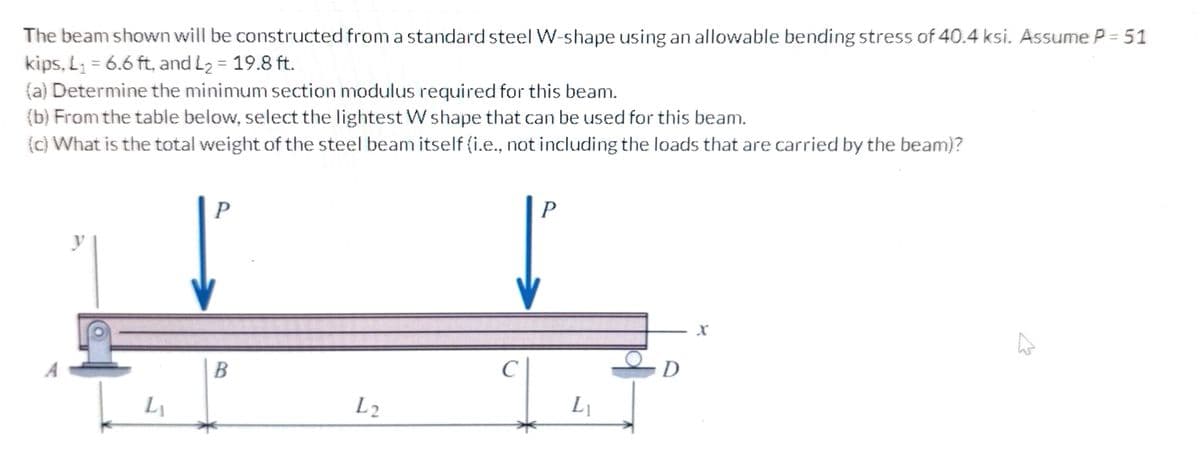

The beam shown will be constructed from a standard steel W-shape using an allowable bending stress of 40.4 ksi. Assume P = 51 kips, L1=6.6 ft, and L2=19.8 ft.

(a) Determine the minimum section modulus required for this beam.

(b) From the table below, select the lightest W shape that can be used for this beam.

(c) What is the total weight of the steel beam itself (i.e., not including the loads that are carried by the beam)?

Transcribed Image Text:The beam shown will be constructed from a standard steel W-shape using an allowable bending stress of 40.4 ksi. Assume P = 51

kips, L₁ = 6.6 ft, and L₂ = 19.8 ft.

(a) Determine the minimum section modulus required for this beam.

(b) From the table below, select the lightest W shape that can be used for this beam.

(c) What is the total weight of the steel beam itself (i.e., not including the loads that are carried by the beam)?

L₁

P

B

L2

с

P

L₁

-D

X

A

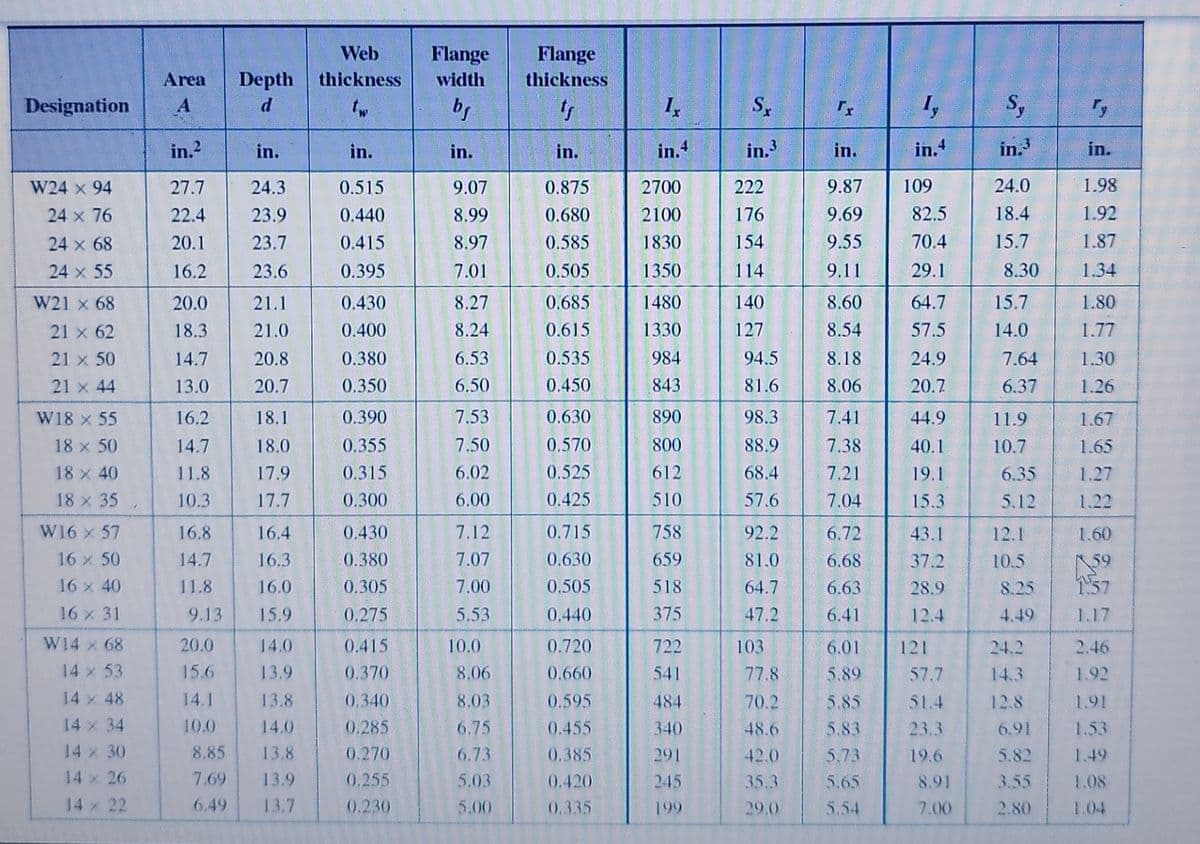

Transcribed Image Text:Designation A

W24 x 94

24 × 76

24 × 68

24 × 55

W21 x 68

21 x 62

21 x 50

21 x 44

W18 x 55

18 x 50

18 × 40

18 x 35

W16 x 57

16 x 50

16 x 40

16 x 31

Area Depth

d

W14 × 68

14 × 53

14 x 48

14 × 34

14 x 30

14 x 26

in.2

27.7

22.4

20.1

16.2

20.0

18.3

14.7

13.0

16.2

14.7

11.8

10.3

16.8

14.7

11.8

in.

24.3

23.9

23.7

23.6

20.0

15.6

14.1

10.0

21.1

21.0

20.8

20.7

16.4

16.3

16.0

9.13 15.9

18.1

18.0

17.9

17.7

14.0

13.9

13.8

14.0

8.85

13.8

7.69

13.9

6.49 13.7

Web

thickness

tw

in.

0.515

0.440

0.415

0.395

0.430

0.400

0.380

0.350

0.390

0.355

0.315

0.300

0.430

0.380

0.305

0.275

0.415

0.370

0.340

0.285

0.270

0.255

0.230

Flange

width

bf

in.

9.07

8.99

8.97

7.01

8.27

8.24

6.53

6.50

7.53

7.50

6.02

6.00

7.12

7.07

7.00

5.53

10.0

8.06

8.03

6.75

6.73

5.03

5.00

Flange

thickness

tr

in.

0.875

0.680

0.585

0.505

0.685

0.615

0.535

0.450

0.630

0.570

0.525

0.425

0.715

0.630

0.505

0.440

0.720

0.660

0.595

0.455

0.385

0.420

0.335

Ix

in.4

2700

2100

1830

1350

1480

1330

984

843

890

800

612

510

758

659

518

375

722

541

484

340

291

245

199

Sx

in.3

222

176

154

114

140

127

94.5

81.6

98.3

88.9

68.4

57.6

92.2

81.0

64.7

47.2

103

77.8

70.2

48.6

42.0

35.3

29.0

in.

9.87

9.69

9.55

9.11

8.60

8.54

8.18

8.06

7.41

7.38

7.21

7.04

6.72

6.68

6.63

6.41

6.01

5.89

5.85

5.83

5.73

5.65

5.54

Ty

in.4

109

82.5

70.4

29.1

64.7

57.5

24.9

20.7

44.9

40.1

19.1

15.3

43.1

37.2

28.9

12.4

121

57.7

51.4

23.3

19.6

8.91

7.00

Sy

in.3

24.0

18.4

15.7

8.30

15.7

14.0

7.64

6.37

11.9

10.7

6.35

5.12

12.1

10.5

8.25

4.49

24.2

14.3

12.8

6.91

5.82

3.55

2.80

Ty

in.

1.98

1.92

1.87

1.34

1.80

1.77

1.30

1.26

1.67

1.65

1.27

1.22

1.60

1.57

1.17

2.46

1.92

1.53

1.49

1.08

1.04

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning