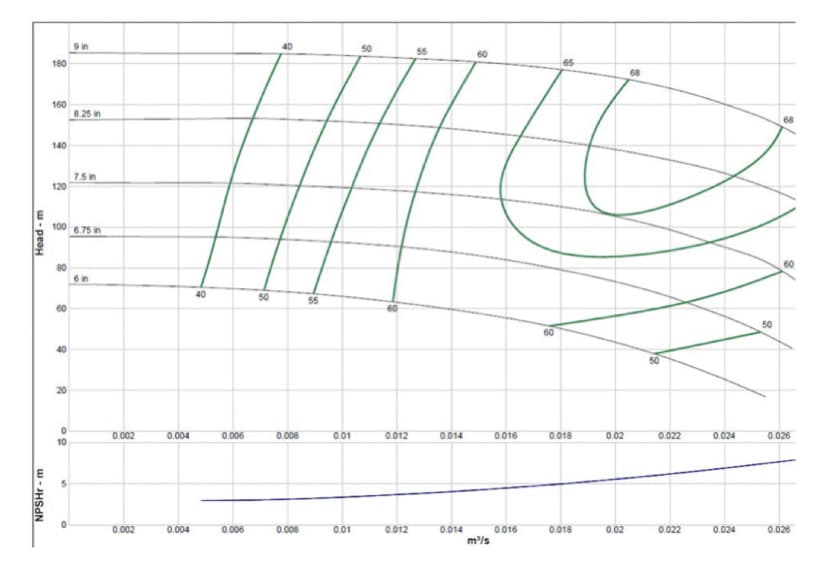

QUESTION 4 The figure below shows a fluid flow system that is designed to pump water at 20 °C from a lower vented reservoir to an elevated vented tank. Note that the drawing is not to scale as the dimensions of the reservoirs are very large relative to those of the piping system. The suction line entering the pump is specified as 20 m of 3½" schedule 40 commercial steel pipe; the discharge line from the pump is 180 m of 2%" schedule 40 commercial steel pipe. 15 m 3 m C. 31/2-in Schedule 40 steel pipe Fully open gate valve 21/2-in Schedule 40 steel pipe Flanged regular 90⁰ elbows Pump Flow Swing-type Butterfly check valve valve (butterfly = 0.8) a. Starting from the Bernoulli equation (in 'head' form) for the situation where the liquid levels in the two reservoirs are reference points 1 and 2, derive the correct equation for pump head Hpump (m) in terms of volumetric flow rate Q (m³/s) and other process variables (e.g. z, f, L, D, K). b. Using Excel (or another suitable program), create a nice plot of Hpump (m) versus Q (m³/s), i.e. the 'system curve'; set your x-axis scale to range from 0 to 0.026 m³/s. Now consider the situation where the pump needs to be replaced. You call up your favourite pump supplier who recommends a particular pump with the pump performance figure shown below. Sketch the 'system demand' curve for the fluid flow system on the pump performance curve shown below (NOTE that the same curve is posted as a separate file in the 'Assignment 5' folder on Avenue) and then identify which one of the five available impellers (i.e. 6", 6.75", 7.5", 8.25", 9") should the supplier install if the system must achieve a volumetric flow rate of 0.020 m³/s. d. For the impeller that you choose in part c, what would be the actual flow rate (m³/s) of water that would be achieved when installed in the system as shown above? Propose a reasonable strategy that could be used to transition the 'operating point' (also referred to as 'duty point') to achieve the desired water flow rate of

QUESTION 4 The figure below shows a fluid flow system that is designed to pump water at 20 °C from a lower vented reservoir to an elevated vented tank. Note that the drawing is not to scale as the dimensions of the reservoirs are very large relative to those of the piping system. The suction line entering the pump is specified as 20 m of 3½" schedule 40 commercial steel pipe; the discharge line from the pump is 180 m of 2%" schedule 40 commercial steel pipe. 15 m 3 m C. 31/2-in Schedule 40 steel pipe Fully open gate valve 21/2-in Schedule 40 steel pipe Flanged regular 90⁰ elbows Pump Flow Swing-type Butterfly check valve valve (butterfly = 0.8) a. Starting from the Bernoulli equation (in 'head' form) for the situation where the liquid levels in the two reservoirs are reference points 1 and 2, derive the correct equation for pump head Hpump (m) in terms of volumetric flow rate Q (m³/s) and other process variables (e.g. z, f, L, D, K). b. Using Excel (or another suitable program), create a nice plot of Hpump (m) versus Q (m³/s), i.e. the 'system curve'; set your x-axis scale to range from 0 to 0.026 m³/s. Now consider the situation where the pump needs to be replaced. You call up your favourite pump supplier who recommends a particular pump with the pump performance figure shown below. Sketch the 'system demand' curve for the fluid flow system on the pump performance curve shown below (NOTE that the same curve is posted as a separate file in the 'Assignment 5' folder on Avenue) and then identify which one of the five available impellers (i.e. 6", 6.75", 7.5", 8.25", 9") should the supplier install if the system must achieve a volumetric flow rate of 0.020 m³/s. d. For the impeller that you choose in part c, what would be the actual flow rate (m³/s) of water that would be achieved when installed in the system as shown above? Propose a reasonable strategy that could be used to transition the 'operating point' (also referred to as 'duty point') to achieve the desired water flow rate of

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Transcribed Image Text:Head-m

NPSHr-m

180

160

140

120

100

80

60

40

20

0

10

9 in

8.25 in

7.5 in

6.75 in

6 in

0.002

0.002

0.004

0.004

40

0.006

0.006

50

40

0.008

0.008

55

0.01

0.01

0.012

0.012

55

0.014

0.014

60

m³/s

0.016

0.016

60

65

0.018

0.018

0.02

0.02

68

0.022

0.022

0.024

0.024

50

60

0.026

0.026

Transcribed Image Text:QUESTION 4

The figure below shows a fluid flow system that is designed to pump water at 20 °C from a lower vented reservoir to

an elevated vented tank. Note that the drawing is not to scale as the dimensions of the reservoirs are very large relative

to those of the piping system. The suction line entering the pump is specified as 20 m of 3½" schedule 40 commercial

steel pipe; the discharge line from the pump is 180 m of 2%" schedule 40 commercial steel pipe.

15 m

3 m

31/2-in Schedule 40

steel pipe

Fully open

gate valve

21/2-in Schedule 40

steel pipe

Flanged

regular

90⁰

elbows

Pump

Flow

Swing-type

check valve valve

Butterfly (K butterfly = 0.8)

a. Starting from the Bernoulli equation (in 'head' form) for the situation where the liquid levels in the two

reservoirs are reference points 1 and 2, derive the correct equation for pump head Hpump (m) in terms of

volumetric flow rate Q (m³/s) and other process variables (e.g. z, f, L, D, K).

b. Using Excel (or another suitable program), create a nice plot of Hpump (m) versus Q (m³/s), i.e. the 'system curve';

set your x-axis scale to range from 0 to 0.026 m³/s.

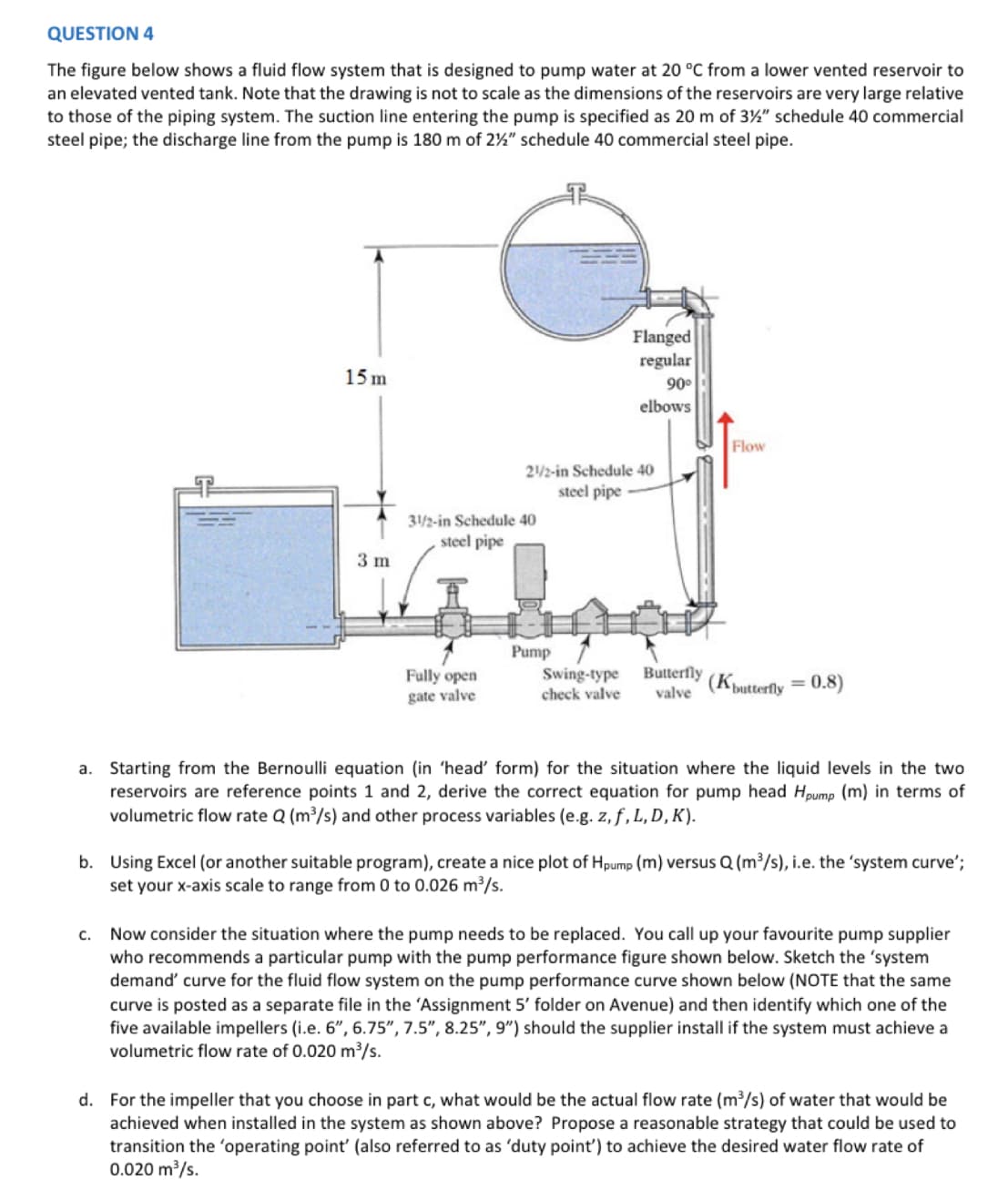

c. Now consider the situation where the pump needs to be replaced. You call up your favourite pump supplier

who recommends a particular pump with the pump performance figure shown below. Sketch the 'system

demand' curve for the fluid flow system on the pump performance curve shown below (NOTE that the same

curve is posted as a separate file in the 'Assignment 5' folder on Avenue) and then identify which one of the

five available impellers (i.e. 6", 6.75", 7.5", 8.25", 9") should the supplier install if the system must achieve a

volumetric flow rate of 0.020 m³/s.

d. For the impeller that you choose in part c, what would be the actual flow rate (m³/s) of water that would be

achieved when installed in the system as shown above? Propose a reasonable strategy that could be used to

transition the 'operating point' (also referred to as 'duty point') to achieve the desired water flow rate of

0.020 m³/s.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

Can you do Part D of this question. Parts A - C have already been done.

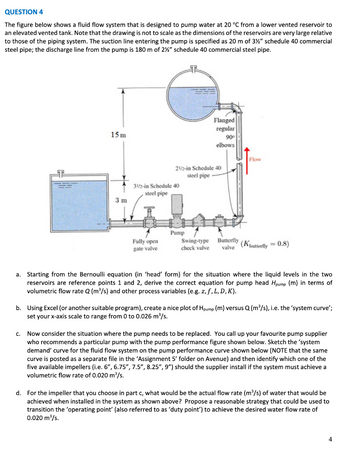

Transcribed Image Text:QUESTION 4

The figure below shows a fluid flow system that is designed to pump water at 20 °C from a lower vented reservoir to

an elevated vented tank. Note that the drawing is not to scale as the dimensions of the reservoirs are very large relative

to those of the piping system. The suction line entering the pump is specified as 20 m of 3½" schedule 40 commercial

steel pipe; the discharge line from the pump is 180 m of 2½" schedule 40 commercial steel pipe.

15 m

3 m

31/2-in Schedule 40

steel pipe

Fully open

gate valve

21/2-in Schedule 40

steel pipe

Pump

Flanged

regular

90⁰

elbows

Swing-type

check valve

Butterfly

valve

Flow

(Kbutterfly = 0.8)

a. Starting from the Bernoulli equation (in 'head' form) for the situation where the liquid levels in the two

reservoirs are reference points 1 and 2, derive the correct equation for pump head Hpump (m) in terms of

volumetric flow rate Q (m³/s) and other process variables (e.g. z, f, L, D,K).

b. Using Excel (or another suitable program), create a nice plot of Hpump (m) versus Q (m³/s), i.e. the 'system curve';

set your x-axis scale to range from 0 to 0.026 m³/s.

c. Now consider the situation where the pump needs to be replaced. You call up your favourite pump supplier

who recommends a particular pump with the pump performance figure shown below. Sketch the 'system

demand' curve for the fluid flow system on the pump performance curve shown below (NOTE that the same

curve is posted as a separate file in the 'Assignment 5' folder on Avenue) and then identify which one of the

five available impellers (i.e. 6", 6.75", 7.5", 8.25", 9") should the supplier install if the system must achieve a

volumetric flow rate of 0.020 m³/s.

d. For the impeller that you choose in part c, what would be the actual flow rate (m³/s) of water that would be

achieved when installed in the system as shown above? Propose a reasonable strategy that could be used to

transition the 'operating point' (also referred to as 'duty point') to achieve the desired water flow rate of

0.020 m³/s.

4

Solution

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY