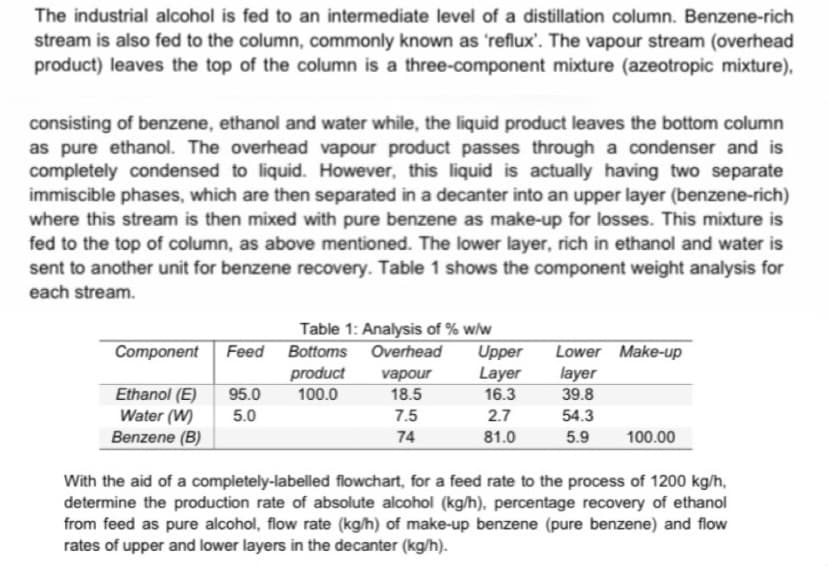

The industrial alcohol is fed to an intermediate level of a distillation column. Benzene-rich stream is also fed to the column, commonly known as 'reflux'. The vapour stream (overhead product) leaves the top of the column is a three-component mixture (azeotropic mixture), consisting of benzene, ethanol and water while, the liquid product leaves the bottom column as pure ethanol. The overhead vapour product passes through a condenser and is completely condensed to liquid. However, this liquid is actually having two separate immiscible phases, which are then separated in a decanter into an upper layer (benzene-rich) where this stream is then mixed with pure benzene as make-up for losses. This mixture is fed to the top of column, as above mentioned. The lower layer, rich in ethanol and water is sent to another unit for benzene recovery. Table 1 shows the component weight analysis for each stream. Feed Component Ethanol (E) 95.0 5.0 Water (W) Benzene (B) Table 1: Analysis of % w/w Bottoms Overhead Upper Layer 16.3 product 100.0 vapour 18.5 7.5 74 2.7 81.0 Lower Make-up layer 39.8 54.3 5.9 100.00 With the aid of a completely-labelled flowchart, for a feed rate to the process of 1200 kg/h, determine the production rate of absolute alcohol (kg/h), percentage recovery of ethanol from feed as pure alcohol, flow rate (kg/h) of make-up benzene (pure benzene) and flow rates of upper and lower layers in the decanter (kg/h).

The industrial alcohol is fed to an intermediate level of a distillation column. Benzene-rich stream is also fed to the column, commonly known as 'reflux'. The vapour stream (overhead product) leaves the top of the column is a three-component mixture (azeotropic mixture), consisting of benzene, ethanol and water while, the liquid product leaves the bottom column as pure ethanol. The overhead vapour product passes through a condenser and is completely condensed to liquid. However, this liquid is actually having two separate immiscible phases, which are then separated in a decanter into an upper layer (benzene-rich) where this stream is then mixed with pure benzene as make-up for losses. This mixture is fed to the top of column, as above mentioned. The lower layer, rich in ethanol and water is sent to another unit for benzene recovery. Table 1 shows the component weight analysis for each stream. Feed Component Ethanol (E) 95.0 5.0 Water (W) Benzene (B) Table 1: Analysis of % w/w Bottoms Overhead Upper Layer 16.3 product 100.0 vapour 18.5 7.5 74 2.7 81.0 Lower Make-up layer 39.8 54.3 5.9 100.00 With the aid of a completely-labelled flowchart, for a feed rate to the process of 1200 kg/h, determine the production rate of absolute alcohol (kg/h), percentage recovery of ethanol from feed as pure alcohol, flow rate (kg/h) of make-up benzene (pure benzene) and flow rates of upper and lower layers in the decanter (kg/h).

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

i really need help to calculate this i already draw the flowchart please help ?

Transcribed Image Text:The industrial alcohol is fed to an intermediate level of a distillation column. Benzene-rich

stream is also fed to the column, commonly known as 'reflux'. The vapour stream (overhead

product) leaves the top of the column is a three-component mixture (azeotropic mixture),

consisting of benzene, ethanol and water while, the liquid product leaves the bottom column

as pure ethanol. The overhead vapour product passes through a condenser and is

completely condensed to liquid. However, this liquid is actually having two separate

immiscible phases, which are then separated in a decanter into an upper layer (benzene-rich)

where this stream is then mixed with pure benzene as make-up for losses. This mixture is

fed to the top of column, as above mentioned. The lower layer, rich in ethanol and water is

sent to another unit for benzene recovery. Table 1 shows the component weight analysis for

each stream.

Table 1: Analysis of % w/w

Upper

Layer

Component

Feed Bottoms Overhead

Lower Make-up

layer

product

100.0

vapour

Ethanol (E)

Water (W)

Benzene (B)

95.0

18.5

16.3

39.8

5.0

7.5

2.7

54.3

74

81.0

5.9

100.00

With the aid of a completely-labelled flowchart, for a feed rate to the process of 1200 kg/h,

determine the production rate of absolute alcohol (kg/h). percentage recovery of ethanol

from feed as pure alcohol, flow rate (kg/h) of make-up benzene (pure benzene) and flow

rates of upper and lower layers in the decanter (kg/h).

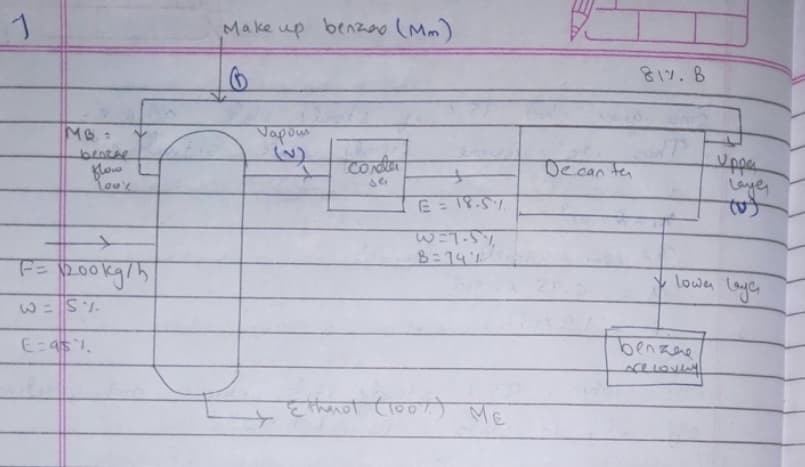

Transcribed Image Text:Make up benzeo (Mm)

817.8

Vapom

(v)

Upper

laye,

Conter

Decan ten

benRne

Blow

se

%3D

7.5.31=

8:14

F=200kg/h

Lown Leye

1. S= 3

benzae

ME

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 5 steps with 1 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The