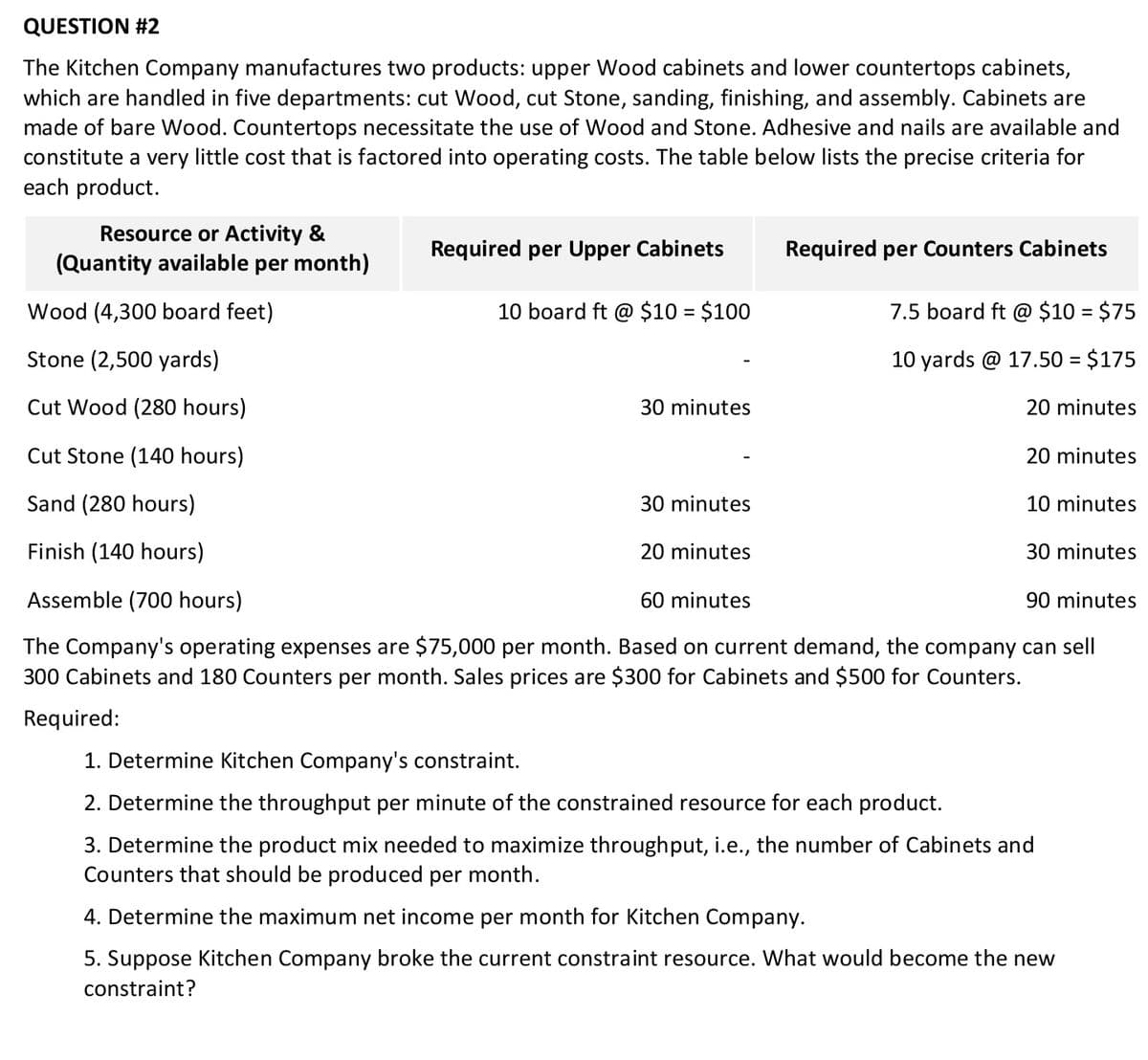

The Kitchen Company manufactures two products: upper Wood cabinets and lower countertops cabinets, which are handled in five departments: cut Wood, cut Stone, sanding, finishing, and assembly. Cabinets are made of bare Wood. Countertops necessitate the use of Wood and Stone. Adhesive and nails are available and constitute a very little cost that is factored into operating costs. The table below lists the precise criteria for each product.

The Kitchen Company manufactures two products: upper Wood cabinets and lower countertops cabinets, which are handled in five departments: cut Wood, cut Stone, sanding, finishing, and assembly. Cabinets are made of bare Wood. Countertops necessitate the use of Wood and Stone. Adhesive and nails are available and constitute a very little cost that is factored into operating costs. The table below lists the precise criteria for each product.

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Transcribed Image Text:QUESTION #2

The Kitchen Company manufactures two products: upper Wood cabinets and lower countertops cabinets,

which are handled in five departments: cut Wood, cut Stone, sanding, finishing, and assembly. Cabinets are

made of bare Wood. Countertops necessitate the use of Wood and Stone. Adhesive and nails are available and

constitute a very little cost that is factored into operating costs. The table below lists the precise criteria for

each product.

Resource or Activity &

(Quantity available per month)

Required per Upper Cabinets

10 board ft @ $10 = $100

Wood (4,300 board feet)

Stone (2,500 yards)

Cut Wood (280 hours)

Cut Stone (140 hours)

Sand (280 hours)

Finish (140 hours)

Assemble (700 hours)

90 minutes

The Company's operating expenses are $75,000 per month. Based on current demand, the company can sell

300 Cabinets and 180 Counters per month. Sales prices are $300 for Cabinets and $500 for Counters.

Required:

30 minutes

30 minutes

20 minutes

Required per Counters Cabinets

60 minutes

7.5 board ft @ $10 = $75

10 yards @ 17.50 = $175

20 minutes

20 minutes

10 minutes

30 minutes

1. Determine Kitchen Company's constraint.

2. Determine the throughput per minute of the constrained resource for each product.

3. Determine the product mix needed to maximize throughput, i.e., the number of Cabinets and

Counters that should be produced per month.

4. Determine the maximum net income per month for Kitchen Company.

5. Suppose Kitchen Company broke the current constraint resource. What would become the new

constraint?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 8 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.