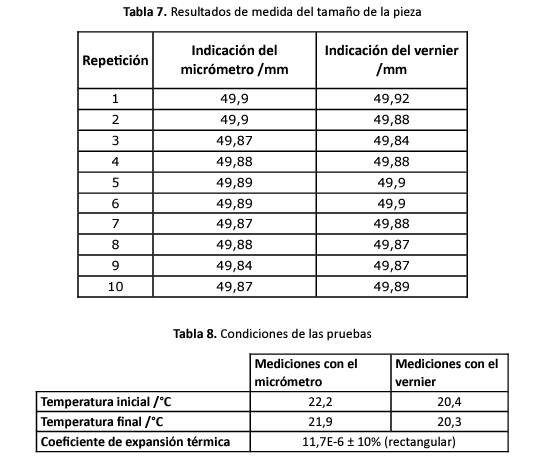

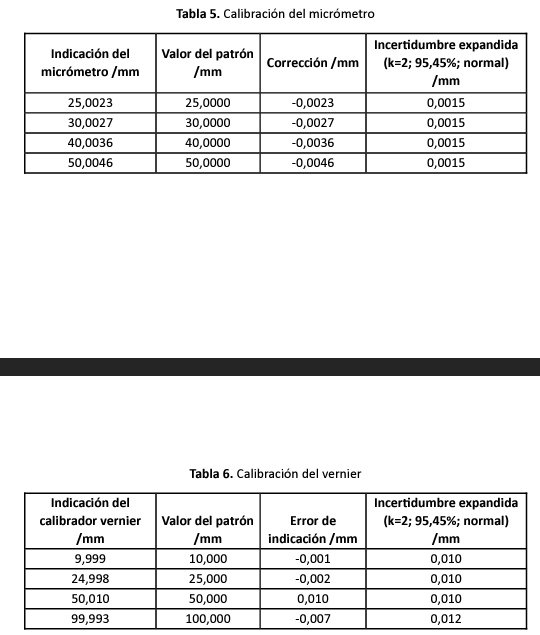

We wish to measure a characteristic of a machined part whose nominal size is 50 mm at 20 °C. For this, two different instruments are used; an analog micrometer and a digital vernier caliper, both recently calibrated and with the same resolution (0.01 mm). The calibration certificate data of the analog micrometer and the digital vernier are shown in tables 5 and 6 respectively. In both cases the calibration uncertainty does not include the contribution of resolution uncertainty. Additionally, there are drift studies for both instruments and it is established that the drift of the micrometer is ± 0.002 mm while the drift of the vernier is ± 0.02 mm. The same number of measurements were performed with both instruments to avoid repeatability biases under controlled environmental conditions. Table 7 shows the results of the measurements of both instruments. The temperature of the piece was monitored with a digital thermometer whose calibration uncertainty is 0.1 °C, which already includes its resolution and its drift is neglected. The conditions during the tests are shown in table 8. • Define the mathematical model for the measurand. Note that the measurand is the size of the part at 20 °C. • Determine the average value of the part size from the micrometer measurements. • Determine the combined standard uncertainty of the part size from the micrometer measurements. Take into account all the sources of uncertainty that are necessary. Neglect any parallax effects. • Calculate the effective degrees of freedom of the measurement uncertainty of the micrometer. • Calculate the expanded uncertainty. Select an appropriate coverage factor for a 95.45% confidence level. • Determine the average value of the part size from the vernier measurements. • Determine the combined standard uncertainty of the part size from vernier measurements. Take into account all the sources of uncertainty that are necessary. • Calculate the effective degrees of freedom of the vernier measurement uncertainty. • Calculate the expanded uncertainty. Select an appropriate coverage factor for a 95.45% confidence level. • Compare the results using a normalized error criterion. Determine if they are statistically equal. • Based on the previous results and your criteria, which instrument is preferable. Discuss the advantages of this instrument based on its use and performance; without commenting on the price.

Theory and Design for Mechanical Measurements

Measurement is a term that refers to analyzing a manufactured component regarding the degree of accuracy for dimensions, tolerances, geometric profile, roundness, flatness, smoothness, etc. Measurement always involves comparing the manufactured component or the prototype with a standard specimen whose dimensions and other parameters are assumed to be perfect and do not undergo changes with respect to time.Precisely in mechanical engineering the branch that deals with the application of scientific principles for measurements is known as metrology. The domain of metrology in general deals with various measurements like mechanical, chemical, thermodynamic, physical, and biological measurements. In mechanical engineering, the measurements are limited to mechanical specific such as length, mass, surface profile, flatness, roundness, viscosity, heat transfer, etc.

Basic principles of engineering metrology

Metrology is described as the science of measurement, precision, and accuracy. In other words, it is a method of measurement based on units and predefined standards.

We wish to measure a characteristic of a machined part whose nominal size is 50 mm at 20 °C. For this, two different instruments are used; an analog micrometer and a digital vernier caliper, both recently calibrated and with the same resolution (0.01 mm). The calibration certificate data of the analog micrometer and the digital vernier are shown in tables 5 and 6 respectively. In both cases the calibration uncertainty does not include the contribution of resolution uncertainty. Additionally, there are drift studies for both instruments and it is established that the drift of the micrometer is ± 0.002 mm while the drift of the vernier is ± 0.02 mm.

The same number of measurements were performed with both instruments to avoid repeatability biases under controlled environmental conditions. Table 7 shows the results of the measurements of both instruments. The temperature of the piece was monitored with a digital thermometer whose calibration uncertainty is 0.1 °C, which already includes its resolution and its drift is neglected. The conditions during the tests are shown in table 8.

• Define the mathematical model for the measurand. Note that the measurand is the size of the part at 20 °C.

• Determine the average value of the part size from the micrometer measurements.

• Determine the combined standard uncertainty of the part size from the micrometer measurements. Take into account all the sources of uncertainty that are necessary. Neglect any parallax effects.

• Calculate the effective degrees of freedom of the measurement uncertainty of the micrometer.

• Calculate the expanded uncertainty. Select an appropriate coverage factor for a 95.45% confidence level.

• Determine the average value of the part size from the vernier measurements.

• Determine the combined standard uncertainty of the part size from vernier measurements. Take into account all the sources of uncertainty that are necessary.

• Calculate the effective degrees of freedom of the vernier measurement uncertainty.

• Calculate the expanded uncertainty. Select an appropriate coverage factor for a 95.45% confidence level.

• Compare the results using a normalized error criterion. Determine if they are statistically equal.

• Based on the previous results and your criteria, which instrument is preferable. Discuss the advantages of this instrument based on its use and performance; without commenting on the price.

Step by step

Solved in 9 steps with 23 images