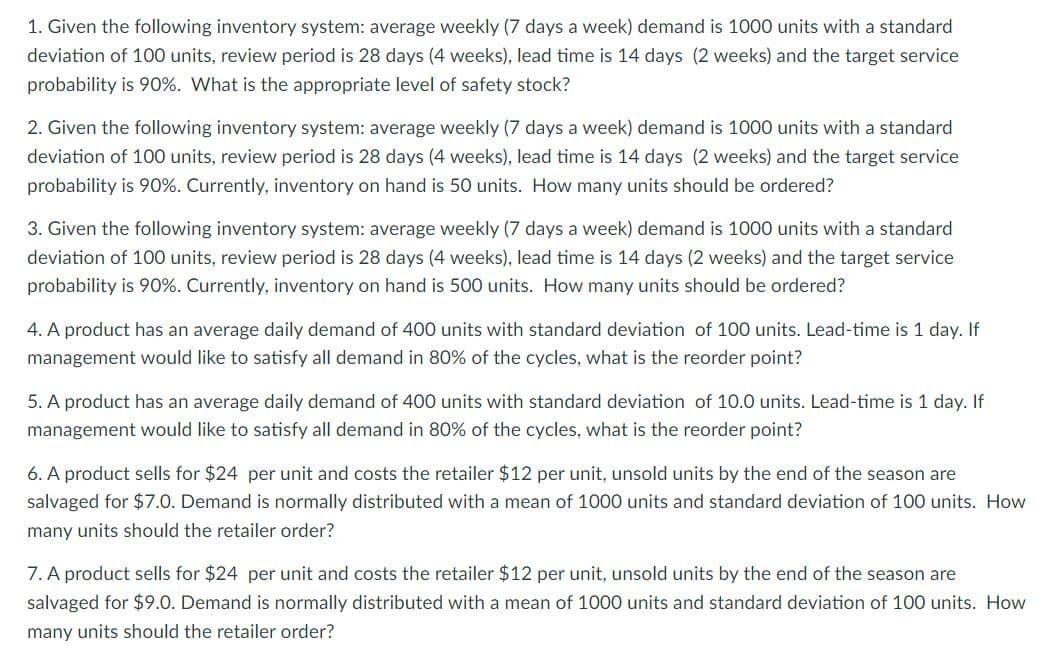

1. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service probability is 90%. What is the appropriate level of safety stock? 2. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service probability is 90%. Currently, inventory on hand is 50 units. How many units should be ordered? 3. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service probability is 90%. Currently, inventory on hand is 500 units. How many units should be ordered? 4. A product has an average daily demand of 400 units with standard deviation of 100 units. Lead-time is 1 day. If management would like to satisfy all demand in 80% of the cycles, what is the reorder point? 5. A product has an average daily demand of 400 units with standard deviation of 10.0 units. Lead-time is 1 day. If management would like to satisfy all demand in 80% of the cycles, what is the reorder point? 6. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are salvaged for $7.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How many units should the retailer order? 7. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are salvaged for $9.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How many units should the retailer order?

1. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service probability is 90%. What is the appropriate level of safety stock? 2. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service probability is 90%. Currently, inventory on hand is 50 units. How many units should be ordered? 3. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service probability is 90%. Currently, inventory on hand is 500 units. How many units should be ordered? 4. A product has an average daily demand of 400 units with standard deviation of 100 units. Lead-time is 1 day. If management would like to satisfy all demand in 80% of the cycles, what is the reorder point? 5. A product has an average daily demand of 400 units with standard deviation of 10.0 units. Lead-time is 1 day. If management would like to satisfy all demand in 80% of the cycles, what is the reorder point? 6. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are salvaged for $7.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How many units should the retailer order? 7. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are salvaged for $9.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How many units should the retailer order?

Purchasing and Supply Chain Management

6th Edition

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Chapter16: Lean Supply Chain Management

Section: Chapter Questions

Problem 10DQ: The chapter presented various approaches for the control of inventory investment. Discuss three...

Related questions

Question

100%

Transcribed Image Text:1. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard

deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service

probability is 90%. What is the appropriate level of safety stock?

2. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard

deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service

probability is 90%. Currently, inventory on hand is 50 units. How many units should be ordered?

3. Given the following inventory system: average weekly (7 days a week) demand is 1000 units with a standard

deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days (2 weeks) and the target service

probability is 90%. Currently, inventory on hand is 500 units. How many units should be ordered?

4. A product has an average daily demand of 400 units with standard deviation of 100 units. Lead-time is 1 day. If

management would like to satisfy all demand in 80% of the cycles, what is the reorder point?

5. A product has an average daily demand of 400 units with standard deviation of 10.0 units. Lead-time is 1 day. If

management would like to satisfy all demand in 80% of the cycles, what is the reorder point?

6. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are

salvaged for $7.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How

many units should the retailer order?

7. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are

salvaged for $9.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How

many units should the retailer order?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Recommended textbooks for you

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning