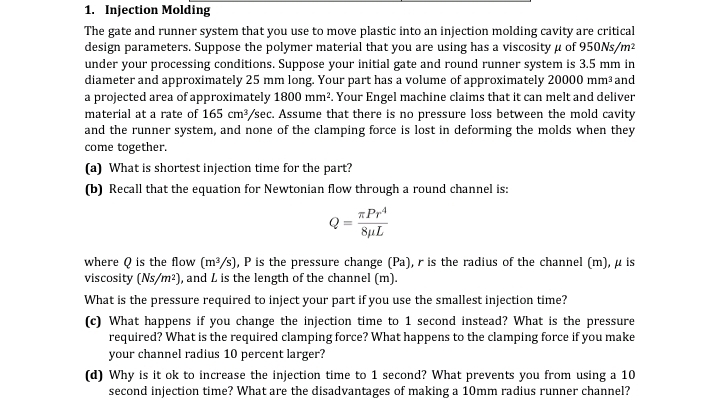

1. Injection Molding The gate and runner system that you use to move plastic into an injection molding cavity are critical design parameters. Suppose the polymer material that you are using has a viscosity μ of 950Ns/m² under your processing conditions. Suppose your initial gate and round runner system is 3.5 mm in diameter and approximately 25 mm long. Your part has a volume of approximately 20000 mm³ and a projected area of approximately 1800 mm². Your Engel machine claims that it can melt and deliver material at a rate of 165 cm³/sec. Assume that there is no pressure loss between the mold cavity and the runner system, and none of the clamping force is lost in deforming the molds when they come together. (a) What is shortest injection time for the part? (b) Recall that the equation for Newtonian flow through a round channel is: Prª Q 8μL where Q is the flow (m³/s), P is the pressure change (Pa), r is the radius of the channel (m), u is viscosity (Ns/m²), and L is the length of the channel (m). What is the pressure required to inject your part if you use the smallest injection time? (c) What happens if you change the injection time to 1 second instead? What is the pressure required? What is the required clamping force? What happens to the clamping force if you make your channel radius 10 percent larger? (d) Why is it ok to increase the injection time to 1 second? What prevents you from using a 10 second injection time? What are the disadvantages of making a 10mm radius runner channel?

1. Injection Molding The gate and runner system that you use to move plastic into an injection molding cavity are critical design parameters. Suppose the polymer material that you are using has a viscosity μ of 950Ns/m² under your processing conditions. Suppose your initial gate and round runner system is 3.5 mm in diameter and approximately 25 mm long. Your part has a volume of approximately 20000 mm³ and a projected area of approximately 1800 mm². Your Engel machine claims that it can melt and deliver material at a rate of 165 cm³/sec. Assume that there is no pressure loss between the mold cavity and the runner system, and none of the clamping force is lost in deforming the molds when they come together. (a) What is shortest injection time for the part? (b) Recall that the equation for Newtonian flow through a round channel is: Prª Q 8μL where Q is the flow (m³/s), P is the pressure change (Pa), r is the radius of the channel (m), u is viscosity (Ns/m²), and L is the length of the channel (m). What is the pressure required to inject your part if you use the smallest injection time? (c) What happens if you change the injection time to 1 second instead? What is the pressure required? What is the required clamping force? What happens to the clamping force if you make your channel radius 10 percent larger? (d) Why is it ok to increase the injection time to 1 second? What prevents you from using a 10 second injection time? What are the disadvantages of making a 10mm radius runner channel?

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Transcribed Image Text:1. Injection Molding

The gate and runner system that you use to move plastic into an injection molding cavity are critical

design parameters. Suppose the polymer material that you are using has a viscosity μ of 950Ns/m²

under your processing conditions. Suppose your initial gate and round runner system is 3.5 mm in

diameter and approximately 25 mm long. Your part has a volume of approximately 20000 mm³ and

a projected area of approximately 1800 mm². Your Engel machine claims that it can melt and deliver

material at a rate of 165 cm³/sec. Assume that there is no pressure loss between the mold cavity

and the runner system, and none of the clamping force is lost in deforming the molds when they

come together.

(a) What is shortest injection time for the part?

(b) Recall that the equation for Newtonian flow through a round channel is:

Pr4

8μL

where Q is the flow (m³/s), P is the pressure change (Pa), r is the radius of the channel (m), u is

viscosity (Ns/m²), and L is the length of the channel (m).

What is the pressure required to inject your part if you use the smallest injection time?

(c) What happens if you change the injection time to 1 second instead? What is the pressure

required? What is the required clamping force? What happens to the clamping force if you make

your channel radius 10 percent larger?

(d) Why is it ok to increase the injection time to 1 second? What prevents you from using a 10

second injection time? What are the disadvantages of making a 10mm radius runner channel?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY