16) Earing is a type of defect, usually found in 17) Tension is the only type of stress applied in 18) --- ------olling mill type are associated with relatively small diameter rolls in contact with the work piece. forming process. forming procese.

16) Earing is a type of defect, usually found in 17) Tension is the only type of stress applied in 18) --- ------olling mill type are associated with relatively small diameter rolls in contact with the work piece. forming process. forming procese.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answer within 20 minutes please please with my best wishes

Transcribed Image Text:forming proces.

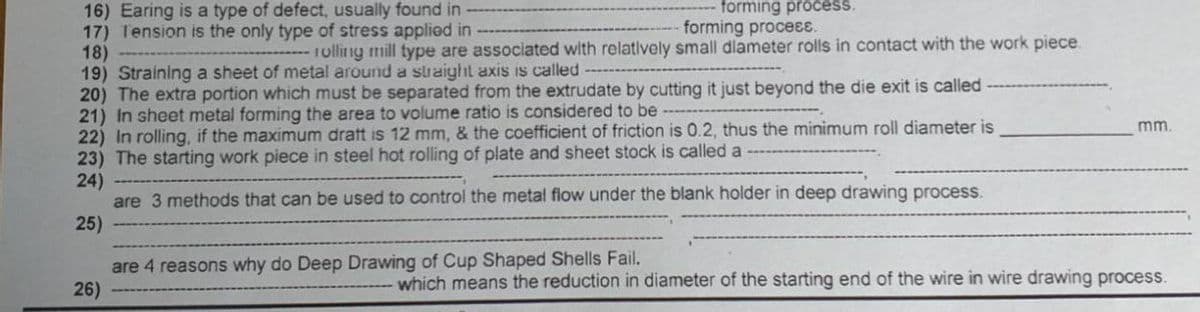

16) Earing is a type of defect, usually found in

17) Tension is the only type of stress applied in

18)

19) Straining a sheet of metal around a straight axis is called

20) The extra portion which must be separated from the extrudate by cutting it just beyond the die exit is called

21) In sheet metal forming the area to volume ratio is considered to be

22) In rolling, if the maximum dratt is 12 mm, & the coefficient of friction is 0.2, thus the minimum roll diameter is

23) The starting work piece in steel hot rolling of plate and sheet stock is called a

24)

are 3 methods that can be used to control the metal flow under the blank holder in deep drawing process.

25)

forming proces8.

rolling mill type are associated with relatlvely small dlameter rolls in contact with the work piece.

mm.

are 4 reasons why do Deep Drawing of Cup Shaped Shells Fail.

26)

which means the reduction in diameter of the starting end of the wire in wire drawing process.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY