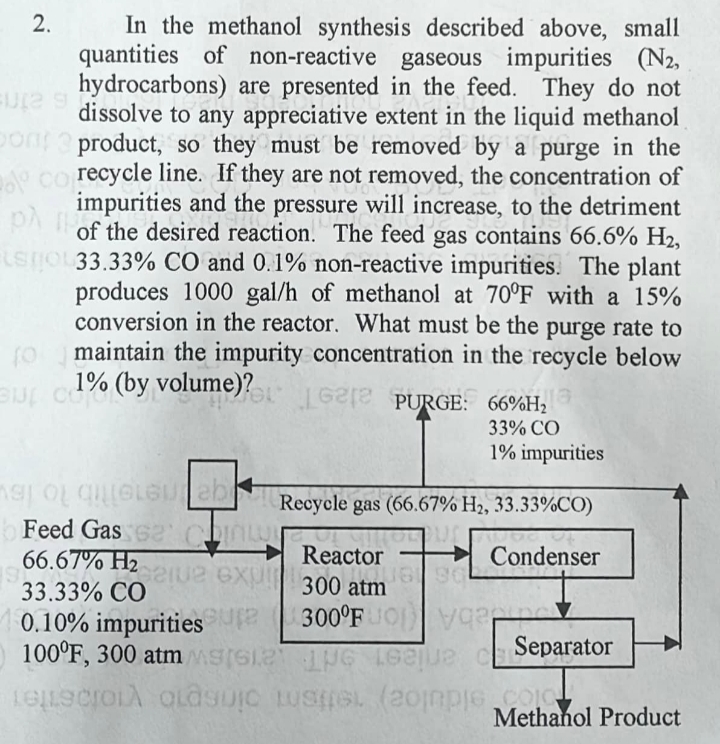

2. In the methanol synthesis described above, small quantities of non-reactive gaseous impurities (N2, hydrocarbons) are presented in the feed. They do not dissolve to any appreciative extent in the liquid methanol product, so they must be removed by a purge in the recycle line. If they are not removed, the concentration of impurities and the pressure will increase, to the detriment of the desired reaction. The feed gas contains 66.6% H₂, SOL33.33% CO and 0.1% non-reactive impurities. The plant produces 1000 gal/h of methanol at 70°F with a 15% conversion in the reactor. What must be the purge rate to maintain the impurity concentration in the recycle below 1% (by volume)? e 16212 PURGE: 66%H₂ 33% CO 1% impurities una (0 up of the ab Feed Gas 62 Cont 66.67% H₂ 22102 exp 33.33% CO 0.10% impurities 100°F, 300 atm MS[61.2 16 esco Olavic Lusts (20mple 118 Recycle gas (66.67% H₂, 33.33%CO) Condenser Reactor 300 atm 300°FUO Vine MOUS SOL Separator col Methanol Product

2. In the methanol synthesis described above, small quantities of non-reactive gaseous impurities (N2, hydrocarbons) are presented in the feed. They do not dissolve to any appreciative extent in the liquid methanol product, so they must be removed by a purge in the recycle line. If they are not removed, the concentration of impurities and the pressure will increase, to the detriment of the desired reaction. The feed gas contains 66.6% H₂, SOL33.33% CO and 0.1% non-reactive impurities. The plant produces 1000 gal/h of methanol at 70°F with a 15% conversion in the reactor. What must be the purge rate to maintain the impurity concentration in the recycle below 1% (by volume)? e 16212 PURGE: 66%H₂ 33% CO 1% impurities una (0 up of the ab Feed Gas 62 Cont 66.67% H₂ 22102 exp 33.33% CO 0.10% impurities 100°F, 300 atm MS[61.2 16 esco Olavic Lusts (20mple 118 Recycle gas (66.67% H₂, 33.33%CO) Condenser Reactor 300 atm 300°FUO Vine MOUS SOL Separator col Methanol Product

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:FUL2 9

In the methanol synthesis described above, small

quantities of non-reactive gaseous impurities (N2,

hydrocarbons) are presented in the feed. They do not

dissolve to any appreciative extent in the liquid methanol

on product, so they must be removed by a purge in the

corecycle line. If they are not removed, the concentration of

impurities and the pressure will increase, to the detriment

of the desired reaction. The feed gas contains 66.6% H₂,

ELSTOL 33.33% CO and 0.1% non-reactive impurities. The plant

produces 1000 gal/h of methanol at 70°F with a 15%

conversion in the reactor. What must be the purge rate to

(0 maintain the impurity concentration in the recycle below

uc1% (by volume)? Gre PURGE: 66%H₂

118

33% CO

1% impurities

2.

mas o que eu ab

Feed Gas 62' Chin

66.67% H₂

33.33% CO

0.10% impuritiessure

Separator

100°F, 300 atm MS

e eue C

relaciona clasic spel (20mple Methanol Product

122102 exu

Recycle gas (66.67% H₂, 33.33%CO)

Condenser

Reactor

300 atm

300°FUO Viney

QUGI SOL

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The