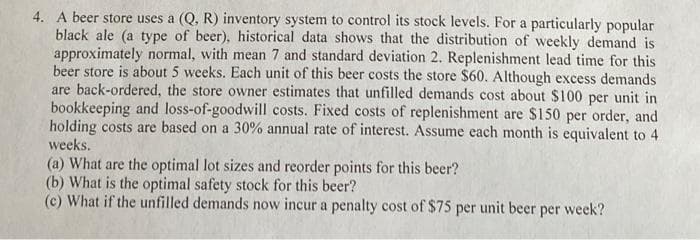

4. A beer store uses a (Q. R) inventory system to control its stock levels. For a particularly popular black ale (a type of beer), historical data shows that the distribution of weekly demand is approximately normal, with mean 7 and standard deviation 2. Replenishment lead time for this beer store is about 5 weeks. Each unit of this beer costs the store $60. Although excess demands are back-ordered, the store owner estimates that unfilled demands cost about $100 per unit in bookkeeping and loss-of-goodwill costs. Fixed costs of replenishment are $150 per order, and holding costs are based on a 30% annual rate of interest. Assume each month is equivalent to 4 weeks. (a) What are the optimal lot sizes and reorder points for this beer? (b) What is the optimal safety stock for this beer? (c) What if the unfilled demands now incur a penalty cost of $75 per unit beer per week?

4. A beer store uses a (Q. R) inventory system to control its stock levels. For a particularly popular black ale (a type of beer), historical data shows that the distribution of weekly demand is approximately normal, with mean 7 and standard deviation 2. Replenishment lead time for this beer store is about 5 weeks. Each unit of this beer costs the store $60. Although excess demands are back-ordered, the store owner estimates that unfilled demands cost about $100 per unit in bookkeeping and loss-of-goodwill costs. Fixed costs of replenishment are $150 per order, and holding costs are based on a 30% annual rate of interest. Assume each month is equivalent to 4 weeks. (a) What are the optimal lot sizes and reorder points for this beer? (b) What is the optimal safety stock for this beer? (c) What if the unfilled demands now incur a penalty cost of $75 per unit beer per week?

Purchasing and Supply Chain Management

6th Edition

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Chapter16: Lean Supply Chain Management

Section: Chapter Questions

Problem 10DQ: The chapter presented various approaches for the control of inventory investment. Discuss three...

Related questions

Question

Transcribed Image Text:4. A beer store uses a (Q, R) inventory system to control its stock levels. For a particularly popular

black ale (a type of beer), historical data shows that the distribution of weekly demand is

approximately normal, with mean 7 and standard deviation 2. Replenishment lead time for this

beer store is about 5 weeks. Each unit of this beer costs the store $60. Although excess demands

are back-ordered, the store owner estimates that unfilled demands cost about $100 per unit in

bookkeeping and loss-of-goodwill costs. Fixed costs of replenishment are $150 per order, and

holding costs are based on a 30% annual rate of interest. Assume each month is equivalent to 4

weeks.

(a) What are the optimal lot sizes and reorder points for this beer?

(b) What is the optimal safety stock for this beer?

(c) What if the unfilled demands now incur a penalty cost of $75 per unit beer per

week?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 1 images

Recommended textbooks for you

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning