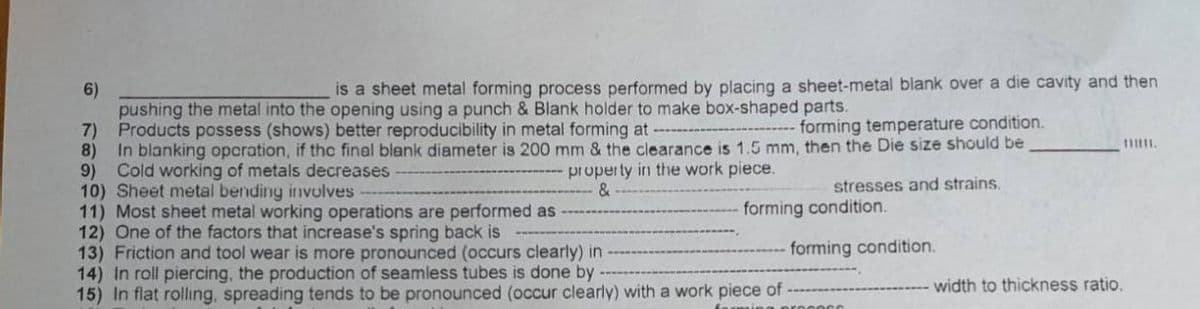

6) is a sheet metal forming process performed by placing a sheet-metal blank over a die cavity and the pushing the metal into the opening using a punch & Blank holder to make box-shaped parts. Products possess (shows) better reproducibility in metal forming at ----- 7) forming temperature condition. 8) In blanking operation, if the final blank diameter is 200 mm & the clearance is 1.5 mm, then the Die size should be 1111 9) Cold working of metals decreases 10) Sheet metal bending involves ------ property in the work piece. stresses and strains.

6) is a sheet metal forming process performed by placing a sheet-metal blank over a die cavity and the pushing the metal into the opening using a punch & Blank holder to make box-shaped parts. Products possess (shows) better reproducibility in metal forming at ----- 7) forming temperature condition. 8) In blanking operation, if the final blank diameter is 200 mm & the clearance is 1.5 mm, then the Die size should be 1111 9) Cold working of metals decreases 10) Sheet metal bending involves ------ property in the work piece. stresses and strains.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answer within 20 minutes please please with my best wishes

Transcribed Image Text:6)

pushing the metal into the opening using a punch & Blank holder to make box-shaped parts.

7) Products possess (shows) better reproducibility in metal forming at -

8)

is a sheet metal forming process performed by placing a sheet-metal blank over a die cavity and then

forming temperature condition.

In blanking opcration, if thc final blank diameter is 200 mm & the clearance is 1.5 mm, then the Die size should be

9) Cold working of metals decreases

10) Sheet metal bending involves

11) Most sheet metal working operations are performed as

12) One of the factors that increase's spring back is

13) Friction and tool wear is more pronounced (occurs clearly) in

14) In roll piercing, the production of seamless tubes is done by

15) In flat rolling, spreading tends to be pronounced (occur clearly) with a work piece of ---

property in the work piece.

&

stresses and strains.

forming condition.

forming condition.

width to thickness ratio.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY