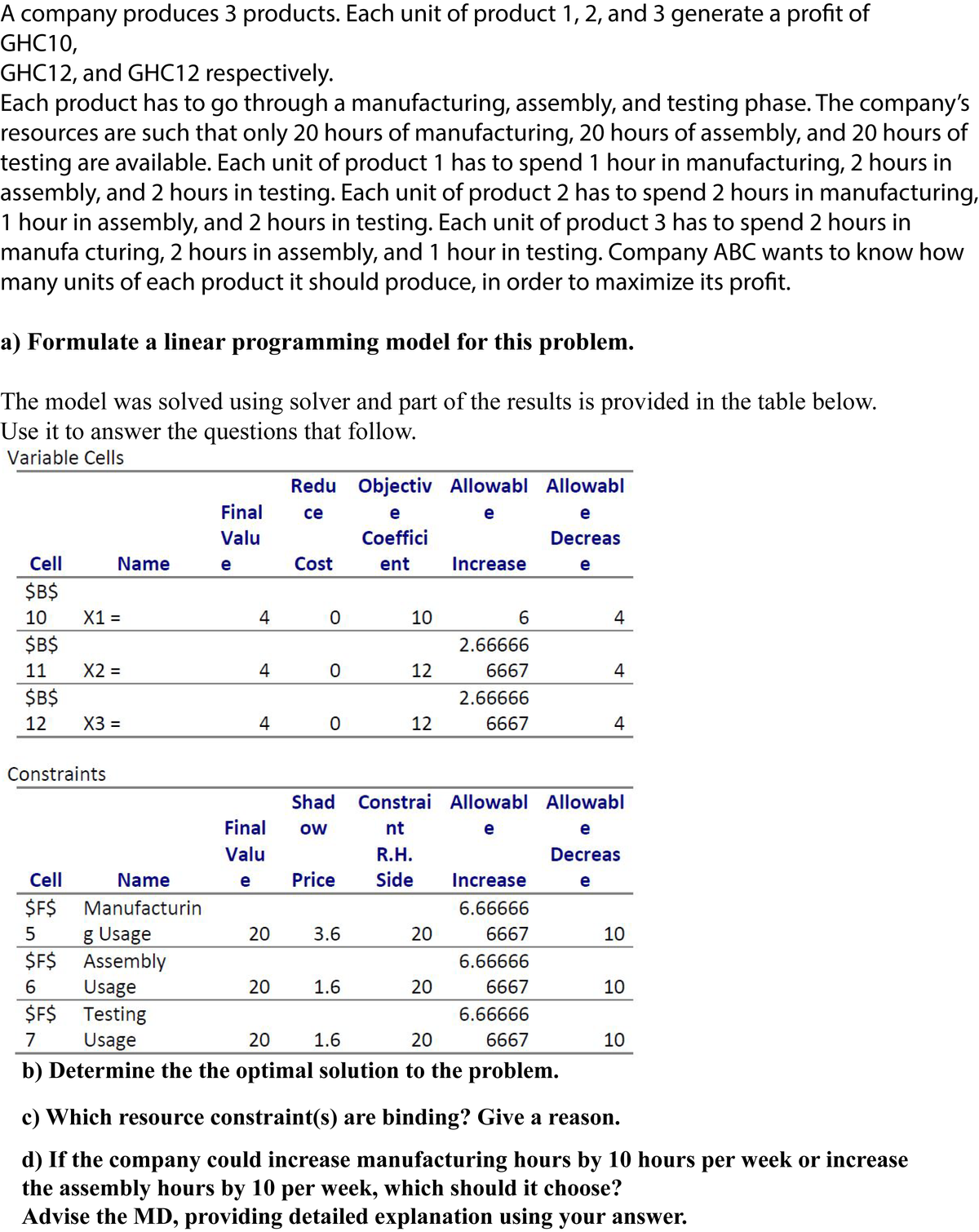

A company produces 3 products. Each unit of product 1, 2, and 3 generate a profit of GHC10, GHC12, and GHC12 respectively. Each product has to go through a manufacturing, assembly, and testing phase. The company's resources are such that only 20 hours of manufacturing, 20 hours of assembly, and 20 hours of testing are available. Each unit of product 1 has to spend 1 hour in manufacturing, 2 hours in assembly, and 2 hours in testing. Each unit of product 2 has to spend 2 hours in manufacturing 1 hour in assembly, and 2 hours in testing. Each unit of product 3 has to spend 2 hours in manufa cturing, 2 hours in assembly, and 1 hour in testing. Company ABC wants to know how many units of each product it should produce, in order to maximize its profit. a) Formulate a linear programming model for this problem. The model was solved using solver and part of the results is provided in the table below. Use it to answer the questions that follow. Variable Cells

A company produces 3 products. Each unit of product 1, 2, and 3 generate a profit of GHC10, GHC12, and GHC12 respectively. Each product has to go through a manufacturing, assembly, and testing phase. The company's resources are such that only 20 hours of manufacturing, 20 hours of assembly, and 20 hours of testing are available. Each unit of product 1 has to spend 1 hour in manufacturing, 2 hours in assembly, and 2 hours in testing. Each unit of product 2 has to spend 2 hours in manufacturing 1 hour in assembly, and 2 hours in testing. Each unit of product 3 has to spend 2 hours in manufa cturing, 2 hours in assembly, and 1 hour in testing. Company ABC wants to know how many units of each product it should produce, in order to maximize its profit. a) Formulate a linear programming model for this problem. The model was solved using solver and part of the results is provided in the table below. Use it to answer the questions that follow. Variable Cells

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter6: Optimization Models With Integer Variables

Section: Chapter Questions

Problem 49P

Related questions

Question

Linear programming company-1

Transcribed Image Text:A company produces 3 products. Each unit of product 1, 2, and 3 generate a profit of

GHC10,

GHC12, and GHC12 respectively.

Each product has to go through a manufacturing, assembly, and testing phase. The company's

resources are such that only 20 hours of manufacturing, 20 hours of assembly, and 20 hours of

testing are available. Each unit of product 1 has to spend 1 hour in manufacturing, 2 hours in

assembly, and 2 hours in testing. Each unit of product 2 has to spend 2 hours in manufacturing,

1 hour in assembly, and 2 hours in testing. Each unit of product 3 has to spend 2 hours in

manufa cturing, 2 hours in assembly, and 1 hour in testing. Company ABC wants to know how

many units of each product it should produce, in order to maximize its profit.

a) Formulate a linear programming model for this problem.

The model was solved using solver and part of the results is provided in the table below.

Use it to answer the questions that follow.

Variable Cells

Redu Objectiv Allowabl Allowabl

Final

се

e

e

e

Valu

Coeffici

Decreas

Cell

Name

e

Cost

ent

Increase

e

$B$

10

X1 =

4

10

6

4

$B$

2.66666

11

X2 =

4

12

6667

4

%3D

$B$

2.66666

12

X3 =

4

12

6667

4

%3D

Constraints

Shad

Constrai Allowabl Allowabl

Final

ow

nt

e

e

Valu

R.H.

Decreas

Cell

Name

e

Price

Side

Increase

e

$F$

Manufacturin

6.66666

g Usage

$F$ Assembly

Usage

$F$ Testing

20

3.6

20

6667

10

6.66666

6.

20

1.6

20

6667

10

6.66666

Usage

b) Determine the the optimal solution to the problem.

7

20

1.6

20

6667

10

c) Which resource constraint(s) are binding? Give a reason.

d) If the company could increase manufacturing hours by 10 hours per week or increase

the assembly hours by 10 per week, which should it choose?

Advise the MD, providing detailed explanation using your answer.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,