A manufacturing company makes two products (denoted as X and Y) through two ma- chines (denoted as A and B). Each unit of X that is produced requires 50 minutes processing time on machine A and another 30 minutes processing time on machine B. Each unit of Y that is produced requires 24 minutes processing time on machine A and another 30 minutes processing time on machine B. At the beginning of this month, there are 49 units of X and 90 units of Y in stock. Available processing time on machine A is forecast to be 40 hours, and on machine B is forecast to be 37 hours. In the current month, the demand for Xis forecast to be 85 units, and the demand for Yis forecast to be 95 units. Under the condition that the demand is met by the end of this month, the company's goal is to maximise the combined sum of the units of X and the units of Y in stock at the end of this month. (1) Formulate the maximisation problem of deciding how many units of each product to make in the current month as a linear programming problem. You need to specify the target function to be maximised, and all constraints to be imposed on the target. (2) Present a hand-drawing graph to illustrate this maximisation problem. A ruler needs to be used when drawing straight lines, and the coordinates on the vertical axis and horizontal axis need to be marked. Note that you can take a photo of your graph and insert it into your Word document (or Latex document). (3) Find out all possible points, which are most likely to be the maximum point (that is, the point which maximises the target function). (4) Of all the points identified in (3), decide which point is the solution to this maximisa- tion problem.

A manufacturing company makes two products (denoted as X and Y) through two ma- chines (denoted as A and B). Each unit of X that is produced requires 50 minutes processing time on machine A and another 30 minutes processing time on machine B. Each unit of Y that is produced requires 24 minutes processing time on machine A and another 30 minutes processing time on machine B. At the beginning of this month, there are 49 units of X and 90 units of Y in stock. Available processing time on machine A is forecast to be 40 hours, and on machine B is forecast to be 37 hours. In the current month, the demand for Xis forecast to be 85 units, and the demand for Yis forecast to be 95 units. Under the condition that the demand is met by the end of this month, the company's goal is to maximise the combined sum of the units of X and the units of Y in stock at the end of this month. (1) Formulate the maximisation problem of deciding how many units of each product to make in the current month as a linear programming problem. You need to specify the target function to be maximised, and all constraints to be imposed on the target. (2) Present a hand-drawing graph to illustrate this maximisation problem. A ruler needs to be used when drawing straight lines, and the coordinates on the vertical axis and horizontal axis need to be marked. Note that you can take a photo of your graph and insert it into your Word document (or Latex document). (3) Find out all possible points, which are most likely to be the maximum point (that is, the point which maximises the target function). (4) Of all the points identified in (3), decide which point is the solution to this maximisa- tion problem.

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

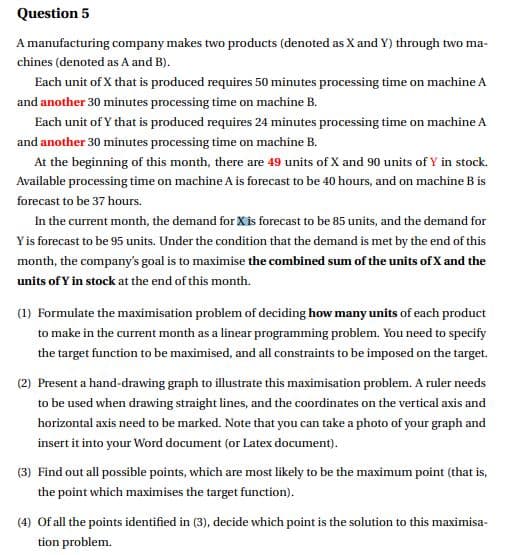

Transcribed Image Text:Question 5

A manufacturing company makes two products (denoted as X and Y) through two ma-

chines (denoted as A and B).

Each unit of X that is produced requires 50 minutes processing time on machine A

and another 30 minutes processing time on machine B.

Each unit of Y that is produced requires 24 minutes processing time on machine A

and another 30 minutes processing time on machine B.

At the beginning of this month, there are 49 units of X and 90 units of Y in stock.

Available processing time on machine A is forecast to be 40 hours, and on machine B is

forecast to be 37 hours.

In the current month, the demand for Xis forecast to be 85 units, and the demand for

Yis forecast to be 95 units. Under the condition that the demand is met by the end of this

month, the company's goal is to maximise the combined sum of the units of X and the

units of Y in stock at the end of this month.

(1) Formulate the maximisation problem of deciding how many units of each product

to make in the current month as a linear programming problem. You need to specify

the target function to be maximised, and all constraints to be imposed on the target.

(2) Present a hand-drawing graph to illustrate this maximisation problem. A ruler needs

to be used when drawing straight lines, and the coordinates on the vertical axis and

horizontal axis need to be marked. Note that you can take a photo of your graph and

insert it into your Word document (or Latex document).

(3) Find out all possible points, which are most likely to be the maximum point (that is,

the point which maximises the target function).

(4) Of all the points identified in (3), decide which point is the solution to this maximisa-

tion problem.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 3 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.