A load of 22 kips is gradually applied to a 2-in round rod, 10 ft long. The total elongation is observed to be 0.03 in. If the stretching is entirely elastic, A. what is the modulus of elasticity, and B. what material would you judge it to be, wrought iron or stainless steel? C. how much energy is absorbed by the rod?

A load of 22 kips is gradually applied to a 2-in round rod, 10 ft long. The total elongation is observed to be 0.03 in. If the stretching is entirely elastic, A. what is the modulus of elasticity, and B. what material would you judge it to be, wrought iron or stainless steel? C. how much energy is absorbed by the rod?

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

A load of 22 kips is gradually applied to a 2-in round rod, 10 ft long. The total elongation is observed to be 0.03 in. If the stretching is entirely elastic,

A. what is the modulus of elasticity, and

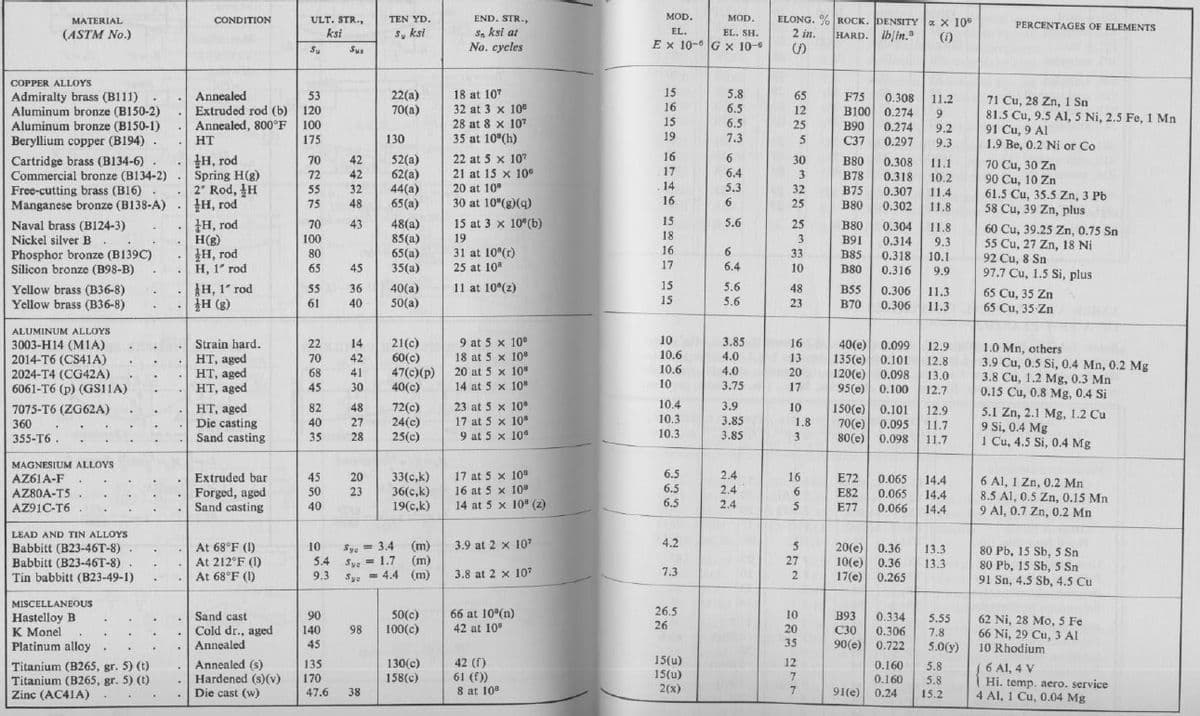

B. what material would you judge it to be, wrought iron or stainless steel?

C. how much energy is absorbed by the rod?

D. Suppose that the material is aluminum alloy 3003-H14 (Table AT 3, Faires); compute its elongation for the same load. Is this within elastic action?

Transcribed Image Text:MOD.

ULT. STR.,

ksi

END. STR.,

S. ksi at

No. cycles

ELONG. % ROCK. DENSITY X 106

2 in.

MATERIAL

CONDITION

TEN YD.

MOD.

PERCENTAGES OF ELEMENTS

s, ksi

(ASTM No.)

EL.

EL. SH.

HARD. Ib/in.

(i)

Ex 10-0 G x 10-6

Su

Sus

COPPER ALLOYS

15

Admiralty brass (B111)

Aluminum bronze (B150-2)

Aluminum bronze (B150-1)

Beryllium copper (B194).

22(a)

70(a)

18 at 107

32 at 3 x 10

5.8

6.5

6.5

Annealed

53

65

F75

0.308

71 Cu, 28 Zn, 1 Sn

81.5 Cu, 9.5 AI, 5 Ni, 2.5 Fe, 1 Mn

91 Cu, 9 Al

1.9 Be, 0.2 Ni or Co

11.2

Extruded rod (b) 120

16

12

B100 0.274

9

28 at 8 x 107

35 at 10°(h)

Annealed, 800°F

100

15

25

B90

0.274

9.2

HT

175

130

19

7.3

5

C37

0.297

9.3

16

IH, rod

Spring H(g)

2" Rod, H

H, rod

22 at 5 x 10"

21 at 15 x 10

20 at 10

30 at 10"(g)(g)

6

Cartridge brass (B134-6)

Commercial bronze (B134-2)

Free-cutting brass (B16)

Manganese bronze (B138-A)

52(a)

62(a)

44(a)

65(a)

70

42

42

30

3

B80

0.308

11.1

10.2

70 Cu, 30 Zn

90 Cu, 10 Zn

61.5 Cu, 35.5 Zn, 3 Pb

58 Cu, 39 Zn, plus

72

17

6.4

B78

B75

0.318

55

32

14

5.3

32

0.307

11.4

75

48

16

6

25

B80

0.302

11.8

15

H, rod

H(g)

H, rod

Н, 1° гod

H, 1" rod

H (g)

15 at 3 x 10°(b)

5.6

48(a)

85(a)

Naval brass (B124-3)

Nickel silverB..

Phosphor bronze (B139C)

Silicon bronze (B98-B)

70

43

25

B80

0.304

0.314

11.8

60 Cu, 39.25 Zn, 0.75 Sn

55 Cu, 27 Zn, 18 Ni

92 Cu, 8 Sn

97.7 Cu, 1.5 Si, plus

100

19

18

3

B91

B85

9.3

16

65(a)

35(a)

31 at 10°(r)

25 at 10

6.

6.4

80

33

0.318

10.1

65

45

17

10

B80

0.316

9.9

15

5.6

Yellow brass (B36-8)

Yellow brass (B36-8)

55

36

40(a)

11 at 10°(z)

48

B55

0.306

11.3

65 Cu, 35 Zn

65 Cu, 35-Zn

61

40

50(a)

15

5.6

23

B70

0.306

11.3

ALUMINUM ALLOYS

9 at 5 x 10

10

3.85

3003-H14 (M1A)

2014-T6 (CS41A)

2024-T4 (CG42A)

6061-T6 (p) (GS11A)

21(c)

60(c)

47(c)(p)

40(c)

40(e) 0.099

135(e) 0.101

120(e)

Strain hard.

22

14

16

12.9

1.0 Mn, others

3.9 Cu, 0.5 Si, 0.4 Mn, 0.2 Mg

3.8 Cu, 1.2 Mg, 0.3 Mn

0.15 Cu, 0.8 Mg, 0.4 Si

10.6

10.6

70

42

18 at 5 x 108

4.0

HT, aged

HT, aged

HT, aged

13

20

12.8

68

41

20 at 5 x 10

4.0

0.098

13.0

45

30

14 at 5 x 10

10

3.75

17

95(e) 0.100

12.7

10.4

23 at 5 x 10

17 at 5 x 10

9 at 5 x 10°

3.9

72(c)

24(c)

7075-T6 (ZG62A)

10

HT, aged

Die casting

Sand casting

82

40

48

150(e)

0.101

70(e) 0.095

80(e) 0.098

12.9

5.1 Zn, 2.1 Mg, 1.2 Cu

9 Si, 0.4 Mg

1 Cu, 4.5 Si, 0.4 Mg

360

27

10.3

3.85

1.8

11.7

355-T6.

35

28

25(c)

10.3

3.85

3

11.7

MAGNESIUM ALLOYS

6.5

33(c,k)

36(c,k)

19(c,k)

Extruded bar

17 at 5 x 10

2.4

45

50

40

20

16

AZ61A-F

AZ80A-T5

E72

0.065

14.4

6 Al, 1 Zn, 0.2 Mn

16 at 5 x 10a

14 at 5 x 10 (2)

6.5

2.4

Forged, aged

Sand casting

23

6.

E82

E77

0.065

14.4

8.5 Al, 0.5 Zn, 0.15 Mn

9 Al, 0.7 Zn, 0.2 Mn

AZ91C-T6

6.5

2.4

5

0.066

14.4

LEAD AND TIN ALLOYS

3.9 at 2 x 107

4.2

20(e) 0.36

10(e) 0.36

17(e) 0.265

(m)

5

At 68°F (1)

At 212°F (1)

At 68°F (1)

10

Babbitt (B23-46T-8) .

Babbitt (B23-46T-8)

Tin babbitt (B23-49-1)

Sye = 3.4

80 Pb, 15 Sb, 5 Sn

80 Pb, 15 Sb, 5 Sn

91 Sn, 4.5 Sb, 4.5 Cu

13.3

5.4

Sye = 1.7 (m)

27

13.3

9.3

Sye = 4.4 (m)

3.8 at 2 x 107

7.3

MISCELLANEOUS

Hastelloy B

K Monel

Platinum alloy

50(c)

100(c)

66 at 10°(n)

42 at 10

26.5

26

10

20

35

90

B93

Sand cast

Cold dr., aged

Annealed

0.334

5.55

7.8

5.0(y)

62 Ni, 28 Mo, 5 Fe

66 Ni, 29 Cu, 3 Al

10 Rhodium

140

98

C30

0.306

45

90(e) 0.722

130(c)

158(c)

42 (f)

61 (f))

8 at 10

15(u)

15(u)

2(x)

12

Annealed (s)

Hardened (s)(v)

Die cast (w)

135

Titanium (B265, gr. 5) (t)

Titanium (B265, gr. 5) (t)

Zinc (AC41A)

0.160

0.160

91(e) 0.24

5.8

6 Al, 4 V

Hi. temp. aero. service

4 AI, 1 Cu, 0.04 Mg

170

7

5.8

47.6

38

7

15.2

...

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY