a. A fleet repair facility has the capacity to repair 800 trucks per month. However, due to scheduled maintenance of their equipment, management feels that they can repair no more than 600 trucks per month. Last month, two of the employees were absent several days each and only 400 trucks were repaired. What are the utilization and efficiency of the repair shop?

a. A fleet repair facility has the capacity to repair 800 trucks per month. However, due to scheduled maintenance of their equipment, management feels that they can repair no more than 600 trucks per month. Last month, two of the employees were absent several days each and only 400 trucks were repaired. What are the utilization and efficiency of the repair shop?

Managerial Economics: A Problem Solving Approach

5th Edition

ISBN:9781337106665

Author:Luke M. Froeb, Brian T. McCann, Michael R. Ward, Mike Shor

Publisher:Luke M. Froeb, Brian T. McCann, Michael R. Ward, Mike Shor

Chapter7: Economies Of Scale And Scope

Section: Chapter Questions

Problem 7.5IP

Related questions

Question

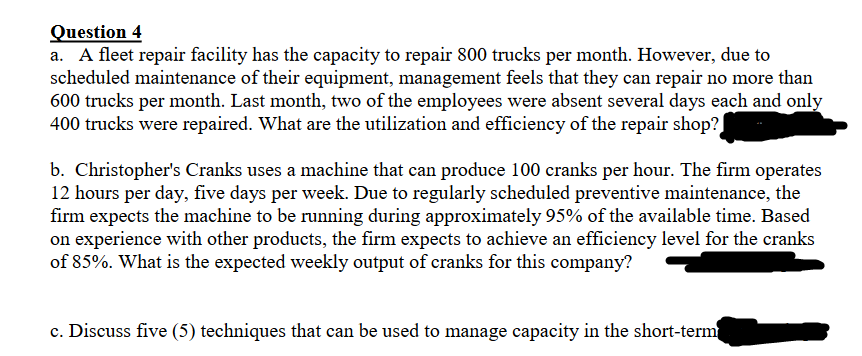

Transcribed Image Text:Question 4

a. A fleet repair facility has the capacity to repair 800 trucks per month. However, due to

scheduled maintenance of their equipment, management feels that they can repair no more than

600 trucks per month. Last month, two of the employees were absent several days each and only

400 trucks were repaired. What are the utilization and efficiency of the repair shop?

b. Christopher's Cranks uses a machine that can produce 100 cranks per hour. The firm operates

12 hours per day, five days per week. Due to regularly scheduled preventive maintenance, the

firm expects the machine to be running during approximately 95% of the available time. Based

on experience with other products, the firm expects to achieve an efficiency level for the cranks

of 85%. What is the expected weekly output of cranks for this company?

c. Discuss five (5) techniques that can be used to manage capacity in the short-term

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, economics and related others by exploring similar questions and additional content below.Recommended textbooks for you

Managerial Economics: A Problem Solving Approach

Economics

ISBN:

9781337106665

Author:

Luke M. Froeb, Brian T. McCann, Michael R. Ward, Mike Shor

Publisher:

Cengage Learning

Microeconomics: Principles & Policy

Economics

ISBN:

9781337794992

Author:

William J. Baumol, Alan S. Blinder, John L. Solow

Publisher:

Cengage Learning

Managerial Economics: A Problem Solving Approach

Economics

ISBN:

9781337106665

Author:

Luke M. Froeb, Brian T. McCann, Michael R. Ward, Mike Shor

Publisher:

Cengage Learning

Microeconomics: Principles & Policy

Economics

ISBN:

9781337794992

Author:

William J. Baumol, Alan S. Blinder, John L. Solow

Publisher:

Cengage Learning

Principles of Economics 2e

Economics

ISBN:

9781947172364

Author:

Steven A. Greenlaw; David Shapiro

Publisher:

OpenStax