An Aluminium workpiece of 175 mm length is machined in a lathe, where the plain tuming openatinin done with th speed steel single point cutting tool The diameter of the workpece got mduced by S mm durng the opeaton As per the wg the required machining lengthas 103 mm and the final diameter is 16 mm. The lathe was set to operate at a spinde pel of 2550 rpm and the camage was set to move with an aal speed of 415 mm/min auomaticaly The et pow Ws/mm ntimaled to& Calculate: (a). Cutting speed (b). Depth of cut (d. Material Removal Rate

An Aluminium workpiece of 175 mm length is machined in a lathe, where the plain tuming openatinin done with th speed steel single point cutting tool The diameter of the workpece got mduced by S mm durng the opeaton As per the wg the required machining lengthas 103 mm and the final diameter is 16 mm. The lathe was set to operate at a spinde pel of 2550 rpm and the camage was set to move with an aal speed of 415 mm/min auomaticaly The et pow Ws/mm ntimaled to& Calculate: (a). Cutting speed (b). Depth of cut (d. Material Removal Rate

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter5: Turning

Section5.3: Machining Operations On The Lathe

Problem 5RQ: Calculate spindle RPM and machining time for cutting a 1.5" diameter 4" long at 225 SFPM using a...

Related questions

Question

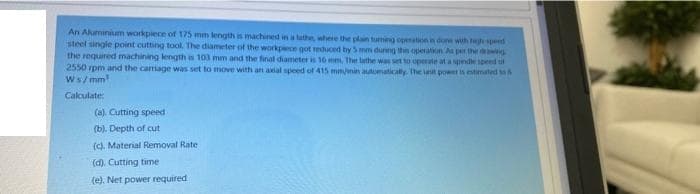

Transcribed Image Text:An Aluminium workpiece of 175 mm length is machined in a lathe, where the plain tuming openatnin done with th spend

steel single point cutting tool. The diameter of the workpece got reduced by 5 mm durng thin operation As per the wng

the required machining lengthis 103 mm and the final diameter is 16 mm, The lathe was set to operate at a spede speed u

2550 rpm and the camage was set to move with an aal speed of 415 mm/min auaomatically. he aut pownt is timated to &

Ws/ mm

Calculate:

(a). Cutting speed

(b). Depth of cut

(d. Material Removal Rate

(d). Cutting time

(e). Net power required

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning