BlueBolt Bottlers has a bottle filling process with a mean value of 58 ounces and a standard deviation of 11.0 ounces a. Suppose that the upper and lower tolerance limits are 64 and 52 ounces, respectively The process capability ratio is (Enter your response rounded to three decimal places) In order for the BlueBolt botting process to meet the tolerance limits 99.7% of the time, the standard deviation would need to be ounces (Enter your response rou one decimal place) b. Now suppose BlueBolt Bottlers makes some process improvements, thereby lowering the standard deviation of the process to 2.5 ounces, rather than 11.0 ounces The process capability ratio is (Enter your response rounded to three decimal places) The improved BlueBolt process able to meet the tolerance limits 99.7% of the time. The enough for BlueBolt Bottlers to achieve Six Sigma quality levels

BlueBolt Bottlers has a bottle filling process with a mean value of 58 ounces and a standard deviation of 11.0 ounces a. Suppose that the upper and lower tolerance limits are 64 and 52 ounces, respectively The process capability ratio is (Enter your response rounded to three decimal places) In order for the BlueBolt botting process to meet the tolerance limits 99.7% of the time, the standard deviation would need to be ounces (Enter your response rou one decimal place) b. Now suppose BlueBolt Bottlers makes some process improvements, thereby lowering the standard deviation of the process to 2.5 ounces, rather than 11.0 ounces The process capability ratio is (Enter your response rounded to three decimal places) The improved BlueBolt process able to meet the tolerance limits 99.7% of the time. The enough for BlueBolt Bottlers to achieve Six Sigma quality levels

Glencoe Algebra 1, Student Edition, 9780079039897, 0079039898, 2018

18th Edition

ISBN:9780079039897

Author:Carter

Publisher:Carter

Chapter10: Statistics

Section10.4: Distributions Of Data

Problem 7PPS

Related questions

Question

Pls ans all

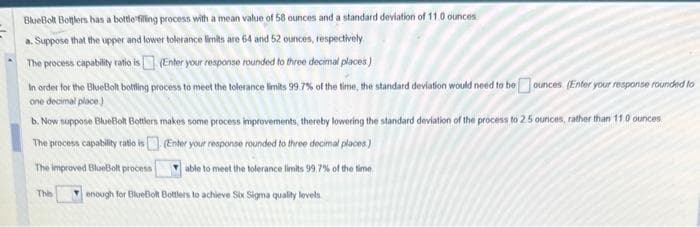

Transcribed Image Text:BlueBolt Bottlers has a bottle filling process with a mean value of 58 ounces and a standard deviation of 11.0 ounces

a. Suppose that the upper and lower tolerance limits are 64 and 52 ounces, respectively

The process capability ratio is

(Enter your response rounded to three decimal places)

In order for the BlueBolt botting process to meet the tolerance limits 99.7% of the time, the standard deviation would need to be ounces (Enter your response rounded to

one decimal place)

b. Now suppose BlueBolt Bottlers makes some process improvements, thereby lowering the standard deviation of the process to 2.5 ounces, rather than 11.0 ounces

The process capability ratio is

(Enter your response rounded to three decimal places)

The improved BlueBolt process

able to meet the tolerance limits 99,7% of the time

Thi

enough for BlueBolt Bottlers to achieve Six Sigma quality levels

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Recommended textbooks for you

Glencoe Algebra 1, Student Edition, 9780079039897…

Algebra

ISBN:

9780079039897

Author:

Carter

Publisher:

McGraw Hill

Glencoe Algebra 1, Student Edition, 9780079039897…

Algebra

ISBN:

9780079039897

Author:

Carter

Publisher:

McGraw Hill