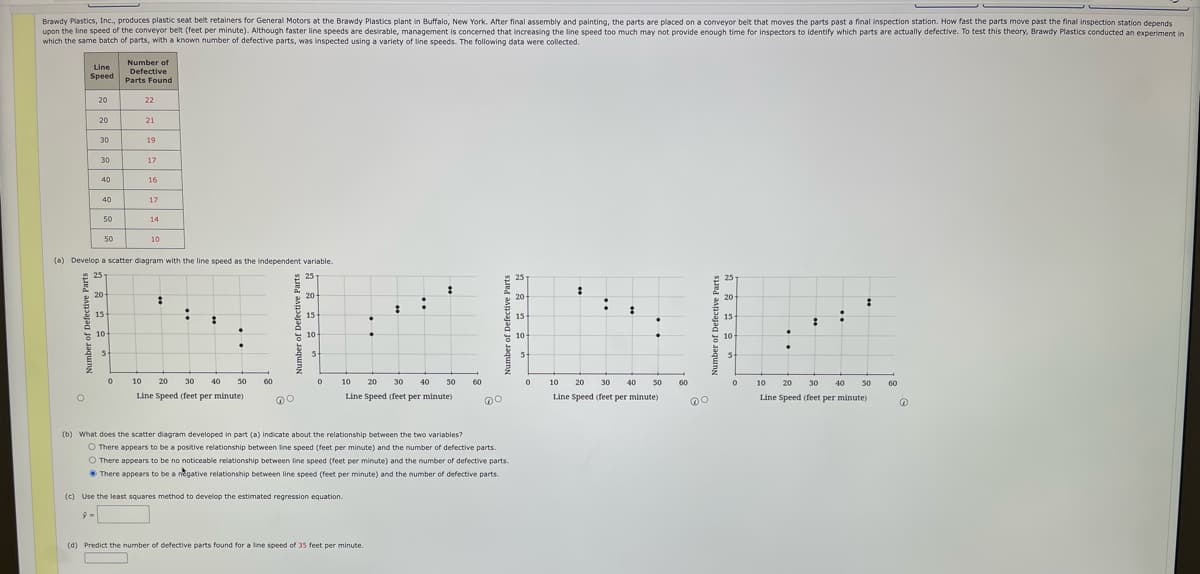

Brawdy Plastics, Inc., produces plastic seat belt retainers for General Motors at the Brawdy Plastics plant in Buffalo, New York. After final assembly and painting, the parts are placed on a comveyor belt that moves the parts past a final inspection station. How fast the parts move past the final inspection station depends upon the line speed of the conveyor belt (feet per minute). Although faster line speeds are desirable, management is concerned that increasing the line speed too much may not provide enough time for inspectors to identify which parts are actually defective. To test this theory, Brawdy Plastics conducted an experiment which the same batch of parts, with a known number of defective parts, was inspected using a variety of line speeds. The following data were collected. Number of Defective Parts Found Line Speed 20 22 20 21 30 19 30 17 40 16 40 17 50 14 50 10 (a) Develop a scatter diagram with the line speed as the independent variable. * 25 25 25 25 20- 20 20 20 2 15- E 15 : 15 15 10- * 10- 10 * 10 5- 5- 5- 10 20 30 40 50 60 10 20 30 40 50 60 10 20 30 40 50 60 10 20 30 40 50 60 Line Speed (feet per minute) Line Speed (feet per minute) Line Speed (feet per minute) Line Speed (feet per minute) (b) What does the scatter diagram developed in part (a) indicate about the relationship between the two variables? O There appears to be a positive relationship between line speed (feet per minute) and the number of defective parts. O There appears to be no noticeable relationship between line speed (feet per minute) and the number of defective parts. • There appears to be a negative relationship between line speed (feet per minute) and the number of defective parts. (c) Use the least squares method to develop the estimated regression equation. (d) Predict the number of defective parts found for a line speed of 35 feet per minute.

Brawdy Plastics, Inc., produces plastic seat belt retainers for General Motors at the Brawdy Plastics plant in Buffalo, New York. After final assembly and painting, the parts are placed on a comveyor belt that moves the parts past a final inspection station. How fast the parts move past the final inspection station depends upon the line speed of the conveyor belt (feet per minute). Although faster line speeds are desirable, management is concerned that increasing the line speed too much may not provide enough time for inspectors to identify which parts are actually defective. To test this theory, Brawdy Plastics conducted an experiment which the same batch of parts, with a known number of defective parts, was inspected using a variety of line speeds. The following data were collected. Number of Defective Parts Found Line Speed 20 22 20 21 30 19 30 17 40 16 40 17 50 14 50 10 (a) Develop a scatter diagram with the line speed as the independent variable. * 25 25 25 25 20- 20 20 20 2 15- E 15 : 15 15 10- * 10- 10 * 10 5- 5- 5- 10 20 30 40 50 60 10 20 30 40 50 60 10 20 30 40 50 60 10 20 30 40 50 60 Line Speed (feet per minute) Line Speed (feet per minute) Line Speed (feet per minute) Line Speed (feet per minute) (b) What does the scatter diagram developed in part (a) indicate about the relationship between the two variables? O There appears to be a positive relationship between line speed (feet per minute) and the number of defective parts. O There appears to be no noticeable relationship between line speed (feet per minute) and the number of defective parts. • There appears to be a negative relationship between line speed (feet per minute) and the number of defective parts. (c) Use the least squares method to develop the estimated regression equation. (d) Predict the number of defective parts found for a line speed of 35 feet per minute.

College Algebra (MindTap Course List)

12th Edition

ISBN:9781305652231

Author:R. David Gustafson, Jeff Hughes

Publisher:R. David Gustafson, Jeff Hughes

Chapter6: Linear Systems

Section6.8: Linear Programming

Problem 5SC: If during the following year it is predicted that each comedy skit will generate 30 thousand and...

Related questions

Question

Transcribed Image Text:Brawdy Plastics, Inc., produces plastic seat belt retainers for General Motors at the Brawdy Plastics plant in Buffalo, New York. After final assembly and painting, the parts are placed on a comveyor belt that moves the parts past a final inspection station. How fast the parts move past the final inspection station depends

upon the line speed of the conveyor belt (feet per minute). Although faster line speeds are desirable, management is concerned that increasing the line speed too much may not provide enough time for inspectors to identify which parts are actually defective. To test this theory, Brawdy Plastics conducted an experiment in

which the same batch of parts, with a known number of defective parts, was inspected using a variety of line speeds. The following data were collected.

Number of

Line

Speed

Defective

Parts Found

20

22

20

21

30

19

30

17

40

16

40

17

50

14

50

10

(a) Develop a scatter diagram with the line speed as the independent variable.

* 25

25

25

25

20-

20

20

20

2

15-

* 15

:

15

15

10-

* 10-

10

* 10

5-

5-

5-

10

20

30

40

50

60

10

20

30

40

50

60

10

20

30

40

50

60

10

20

30

40

50

60

Line Speed (feet per minute)

Line Speed (feet per minute)

Line Speed (feet per minute)

Line Speed (feet per minute)

(b) What does the scatter diagram developed in part (a) indicate about the relationship between the two variables?

O There appears to be a positive relationship between line speed (feet per minute) and the number of defective parts.

O There appears to be no noticeable relationship between line speed (feet per minute) and the number of defective parts.

• There appears to be a negative relationship between line speed (feet per minute) and the number of defective parts.

(c) Use the least squares method to develop the estimated regression equation.

(d) Predict the number of defective parts found for a line speed of 35 feet per minute.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images

Recommended textbooks for you

College Algebra (MindTap Course List)

Algebra

ISBN:

9781305652231

Author:

R. David Gustafson, Jeff Hughes

Publisher:

Cengage Learning

Algebra for College Students

Algebra

ISBN:

9781285195780

Author:

Jerome E. Kaufmann, Karen L. Schwitters

Publisher:

Cengage Learning

College Algebra (MindTap Course List)

Algebra

ISBN:

9781305652231

Author:

R. David Gustafson, Jeff Hughes

Publisher:

Cengage Learning

Algebra for College Students

Algebra

ISBN:

9781285195780

Author:

Jerome E. Kaufmann, Karen L. Schwitters

Publisher:

Cengage Learning

Elementary Algebra

Algebra

ISBN:

9780998625713

Author:

Lynn Marecek, MaryAnne Anthony-Smith

Publisher:

OpenStax - Rice University

Glencoe Algebra 1, Student Edition, 9780079039897…

Algebra

ISBN:

9780079039897

Author:

Carter

Publisher:

McGraw Hill