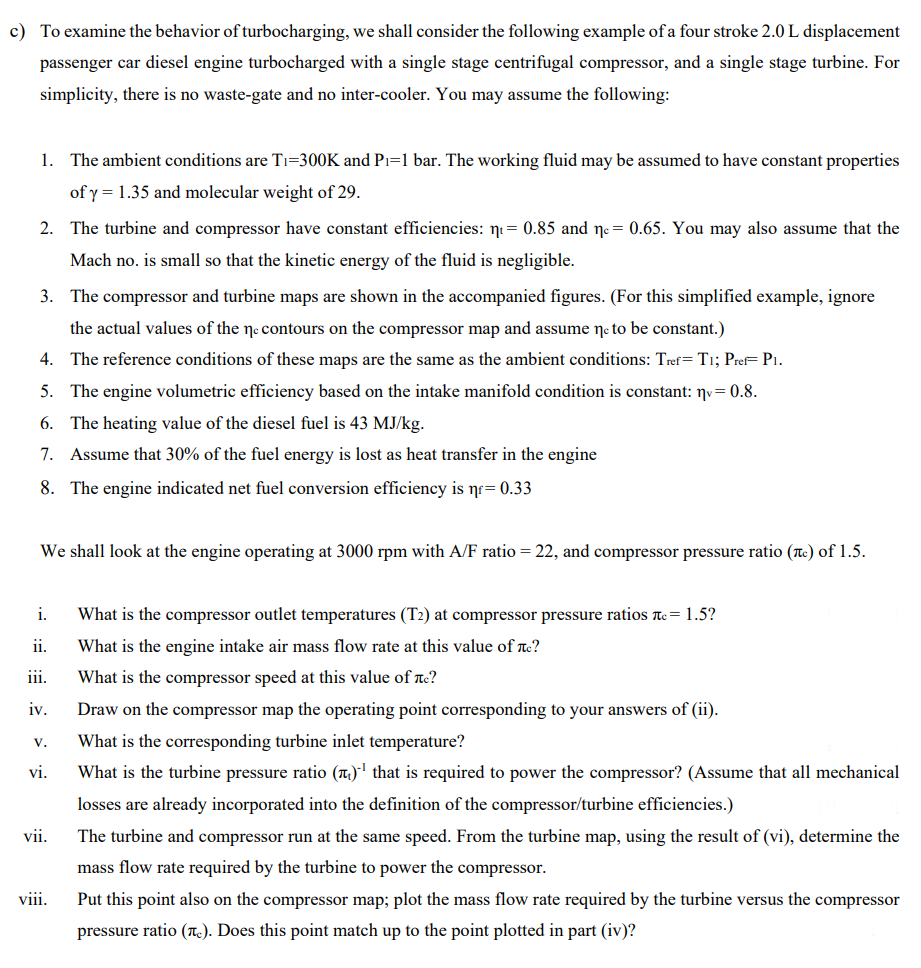

c) To examine the behavior of turbocharging, we shall consider the following example of a four stroke 2.0 L displacement passenger car diesel engine turbocharged with a single stage centrifugal compressor, and a single stage turbine. For simplicity, there is no waste-gate and no inter-cooler. You may assume the following: 1. The ambient conditions are Ti=300K and Pi=1 bar. The working fluid may be assumed to have constant properties of y = 1.35 and molecular weight of 29. 2. The turbine and compressor have constant efficiencies: ni= 0.85 and ne= 0.65. You may also assume that the Mach no. is small so that the kinetic energy of the fluid is negligible. 3. The compressor and turbine maps are shown in the accompanied figures. (For this simplified example, ignore the actual values of the ŋe contours on the compressor map and assume ne to be constant.) 4. The reference conditions of these maps are the same as the ambient conditions: Tref= T1; PreF Pi. 5. The engine volumetric efficiency based on the intake manifold condition is constant: ŋv= 0.8. 6. The heating value of the diesel fuel is 43 MJ/kg. 7. Assume that 30% of the fuel energy is lost as heat transfer in the engine 8. The engine indicated net fuel conversion efficiency is nr= 0.33 We shall look at the engine operating at 3000 rpm with A/F ratio = 22, and compressor pressure ratio (tc) of 1.5. i. What is the compressor outlet temperatures (T2) at compressor pressure ratios nc= 1.5? ii. What is the engine intake air mass flow rate at this value of rc? iii. What is the compressor speed at this value of rc? iv. Draw on the compressor map the operating point corresponding to your answers of (ii). V. What is the corresponding turbine inlet temperature? vi. What is the turbine pressure ratio (1.) that is required to power the compressor? (Assume that all mechanical losses are already incorporated into the definition of the compressor/turbine efficiencies.) vii. The turbine and compressor run at the same speed. From the turbine map, using the result of (vi), determine the mass flow rate required by the turbine to power the compressor. viii. Put this point also on the compressor map; plot the mass flow rate required by the turbine versus the compressor pressure ratio (1.). Does this point match up to the point plotted in part (iv)?

c) To examine the behavior of turbocharging, we shall consider the following example of a four stroke 2.0 L displacement passenger car diesel engine turbocharged with a single stage centrifugal compressor, and a single stage turbine. For simplicity, there is no waste-gate and no inter-cooler. You may assume the following: 1. The ambient conditions are Ti=300K and Pi=1 bar. The working fluid may be assumed to have constant properties of y = 1.35 and molecular weight of 29. 2. The turbine and compressor have constant efficiencies: ni= 0.85 and ne= 0.65. You may also assume that the Mach no. is small so that the kinetic energy of the fluid is negligible. 3. The compressor and turbine maps are shown in the accompanied figures. (For this simplified example, ignore the actual values of the ŋe contours on the compressor map and assume ne to be constant.) 4. The reference conditions of these maps are the same as the ambient conditions: Tref= T1; PreF Pi. 5. The engine volumetric efficiency based on the intake manifold condition is constant: ŋv= 0.8. 6. The heating value of the diesel fuel is 43 MJ/kg. 7. Assume that 30% of the fuel energy is lost as heat transfer in the engine 8. The engine indicated net fuel conversion efficiency is nr= 0.33 We shall look at the engine operating at 3000 rpm with A/F ratio = 22, and compressor pressure ratio (tc) of 1.5. i. What is the compressor outlet temperatures (T2) at compressor pressure ratios nc= 1.5? ii. What is the engine intake air mass flow rate at this value of rc? iii. What is the compressor speed at this value of rc? iv. Draw on the compressor map the operating point corresponding to your answers of (ii). V. What is the corresponding turbine inlet temperature? vi. What is the turbine pressure ratio (1.) that is required to power the compressor? (Assume that all mechanical losses are already incorporated into the definition of the compressor/turbine efficiencies.) vii. The turbine and compressor run at the same speed. From the turbine map, using the result of (vi), determine the mass flow rate required by the turbine to power the compressor. viii. Put this point also on the compressor map; plot the mass flow rate required by the turbine versus the compressor pressure ratio (1.). Does this point match up to the point plotted in part (iv)?

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

internal combustion engine. please help as much as possible

Transcribed Image Text:c) To examine the behavior of turbocharging, we shall consider the following example of a four stroke 2.0 L displacement

passenger car diesel engine turbocharged with a single stage centrifugal compressor, and a single stage turbine. For

simplicity, there is no waste-gate and no inter-cooler. You may assume the following:

1. The ambient conditions are Tı=300K and Pi=1 bar. The working fluid may be assumed to have constant properties

of y = 1.35 and molecular weight of 29.

2. The turbine and compressor have constant efficiencies: ni= 0.85 and ne= 0.65. You may also assume that the

Mach no. is small so that the kinetic energy of the fluid is negligible.

3. The compressor and turbine maps are shown in the accompanied figures. (For this simplified example, ignore

the actual values of the ne contours on the compressor map and assume ne to be constant.)

4. The reference conditions of these maps are the same as the ambient conditions: Tref= T1; Pref= P1.

5. The engine volumetric efficiency based on the intake manifold condition is constant: nv= 0.8.

6. The heating value of the diesel fuel is 43 MJ/kg.

7. Assume that 30% of the fuel energy is lost as heat transfer in the engine

8. The engine indicated net fuel conversion efficiency is nr= 0.33

We shall look at the engine operating at 3000 rpm with A/F ratio = 22, and compressor pressure ratio (Tc) of 1.5.

i.

What is the compressor outlet temperatures (T2) at compressor pressure ratios Tc= 1.5?

ii.

What is the engine intake air mass flow rate at this value of Tc?

ii.

What is the compressor speed at this value of rc?

iv.

Draw on the compressor map the operating point corresponding to your answers of (ii).

What is the corresponding turbine inlet temperature?

V.

vi.

What is the turbine pressure ratio (a)l that is required to power the compressor? (Assume that all mechanical

losses are already incorporated into the definition of the compressor/turbine efficiencies.)

vii.

The turbine and compressor run at the same speed. From the turbine map, using the result of (vi), determine the

mass flow rate required by the turbine to power the compressor.

viii.

Put this point also on the compressor map; plot the mass flow rate required by the turbine versus the compressor

pressure ratio (.). Does this point match up to the point plotted in part (iv)?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY