c. Using the results from part (a), how long will it take for the paint to completely dry? d. What are the hydrodynamic (8) and concentration boundary- layer (6) thicknesses at x=L=1.5 m? How does this compare to H, the height of the drying chamber? What is the new required air flow rate (m³/min) if the desired solvent mass-transfer rate is 150 g/min?

c. Using the results from part (a), how long will it take for the paint to completely dry? d. What are the hydrodynamic (8) and concentration boundary- layer (6) thicknesses at x=L=1.5 m? How does this compare to H, the height of the drying chamber? What is the new required air flow rate (m³/min) if the desired solvent mass-transfer rate is 150 g/min?

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter9: Heat Transfer With Phase Change

Section: Chapter Questions

Problem 9.28P

Related questions

Question

Please state when values are sources from an appendix/table.

Transcribed Image Text:Using the results from part (a), how long will it take for the

paint to completely dry?

d. What are the hydrodynamic (8) and concentration boundary-

layer (8) thicknesses at x=L=1.5 m? How does this

compare to H, the height of the drying chamber?

What is the new required air flow rate (m³/min) if the desired

solvent mass-transfer rate is 150 g/min?

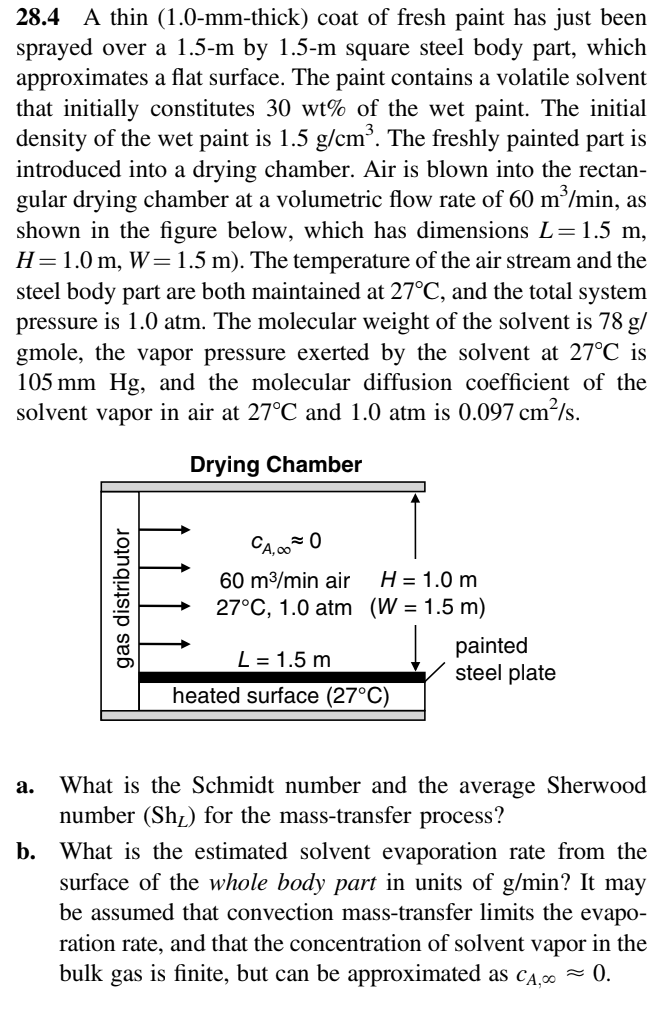

Transcribed Image Text:28.4 A thin (1.0-mm-thick) coat of fresh paint has just been

sprayed over a 1.5-m by 1.5-m square steel body part, which

approximates a flat surface. The paint contains a volatile solvent

that initially constitutes 30 wt% of the wet paint. The initial

density of the wet paint is 1.5 g/cm³. The freshly painted part is

introduced into a drying chamber. Air is blown into the rectan-

gular drying chamber at a volumetric flow rate of 60 m³/min, as

shown in the figure below, which has dimensions L = 1.5 m,

H=1.0 m, W= 1.5 m). The temperature of the air stream and the

steel body part are both maintained at 27°C, and the total system

pressure is 1.0 atm. The molecular weight of the solvent is 78 g/

gmole, the vapor pressure exerted by the solvent at 27°C is

105 mm Hg, and the molecular diffusion coefficient of the

solvent vapor in air at 27°C and 1.0 atm is 0.097 cm²/s.

Drying Chamber

gas distributor

CA,000

60 m³/min air

H = 1.0 m

27°C, 1.0 atm (W = 1.5 m)

L = 1.5 m

heated surface (27°C)

painted

steel plate

a. What is the Schmidt number and the average Sherwood

number (Sh₂) for the mass-transfer process?

b. What is the estimated solvent evaporation rate from the

surface of the whole body part in units of g/min? It may

be assumed that convection mass-transfer limits the evapo-

ration rate, and that the concentration of solvent vapor in the

bulk gas is finite, but can be approximated as CA, ≈ 0.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 9 steps with 8 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning