C3H6+ C6H6C9H12

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

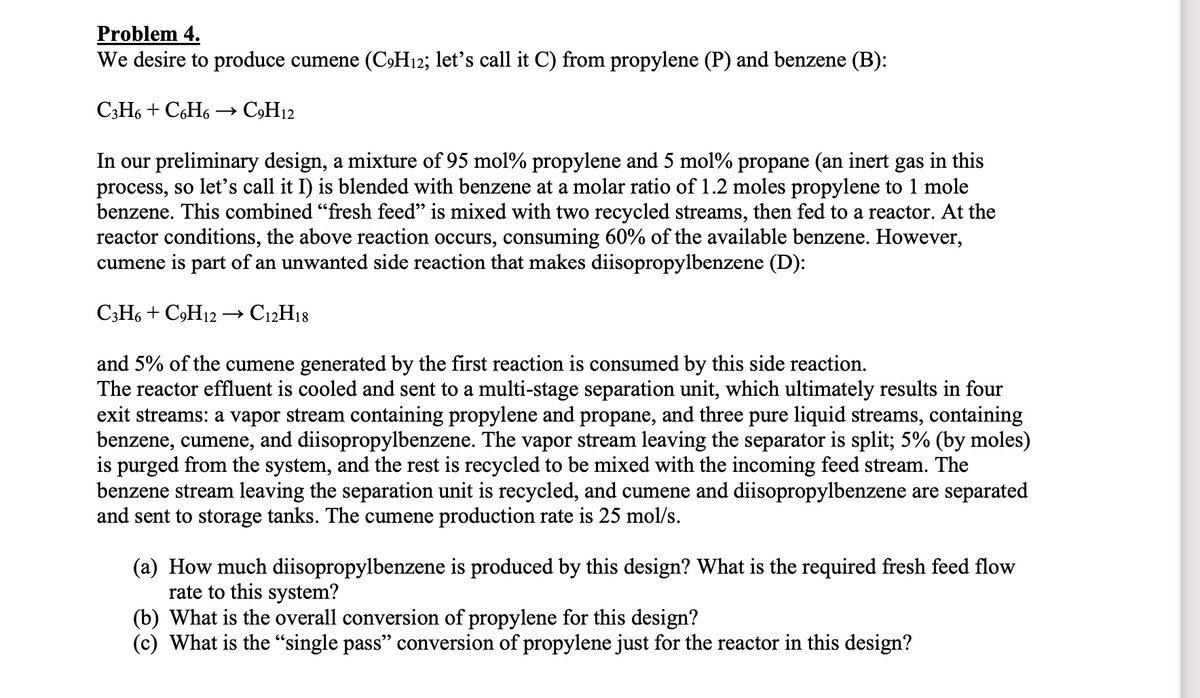

Transcribed Image Text:Problem 4.

We desire to produce cumene (C₂H₁2; let's call it C) from propylene (P) and benzene (B):

C3H6+ C6H6 → C9H12

In our preliminary design, a mixture of 95 mol% propylene and 5 mol% propane (an inert gas in this

process, so let's call it I) is blended with benzene at a molar ratio of 1.2 moles propylene to 1 mole

benzene. This combined "fresh feed" is mixed with two recycled streams, then fed to a reactor. At the

reactor conditions, the above reaction occurs, consuming 60% of the available benzene. However,

cumene is part of an unwanted side reaction that makes diisopropylbenzene (D):

C3H6+ C9H12 → C12H18

and 5% of the cumene generated by the first reaction is consumed by this side reaction.

The reactor effluent is cooled and sent to a multi-stage separation unit, which ultimately results in four

exit streams: a vapor stream containing propylene and propane, and three pure liquid streams, containing

benzene, cumene, and diisopropylbenzene. The vapor stream leaving the separator is split; 5% (by moles)

is purged from the system, and the rest is recycled to be mixed with the incoming feed stream. The

benzene stream leaving the separation unit is recycled, and cumene and diisopropylbenzene are separated

and sent to storage tanks. The cumene production rate is 25 mol/s.

(a) How much diisopropylbenzene is produced by this design? What is the required fresh feed flow

rate to this system?

(b) What is the overall conversion of propylene for this design?

(c) What is the "single pass" conversion of propylene just for the reactor in this design?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The