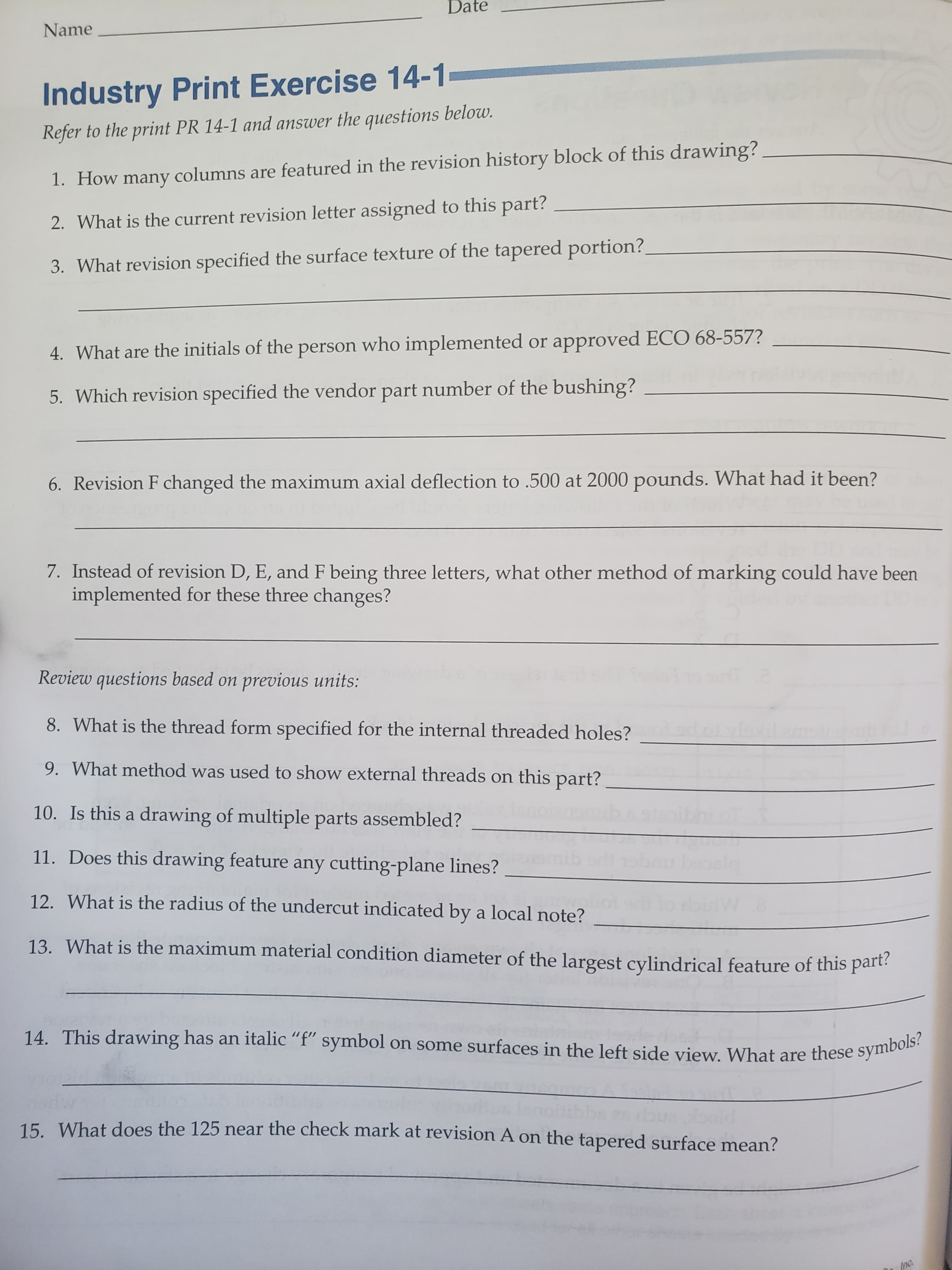

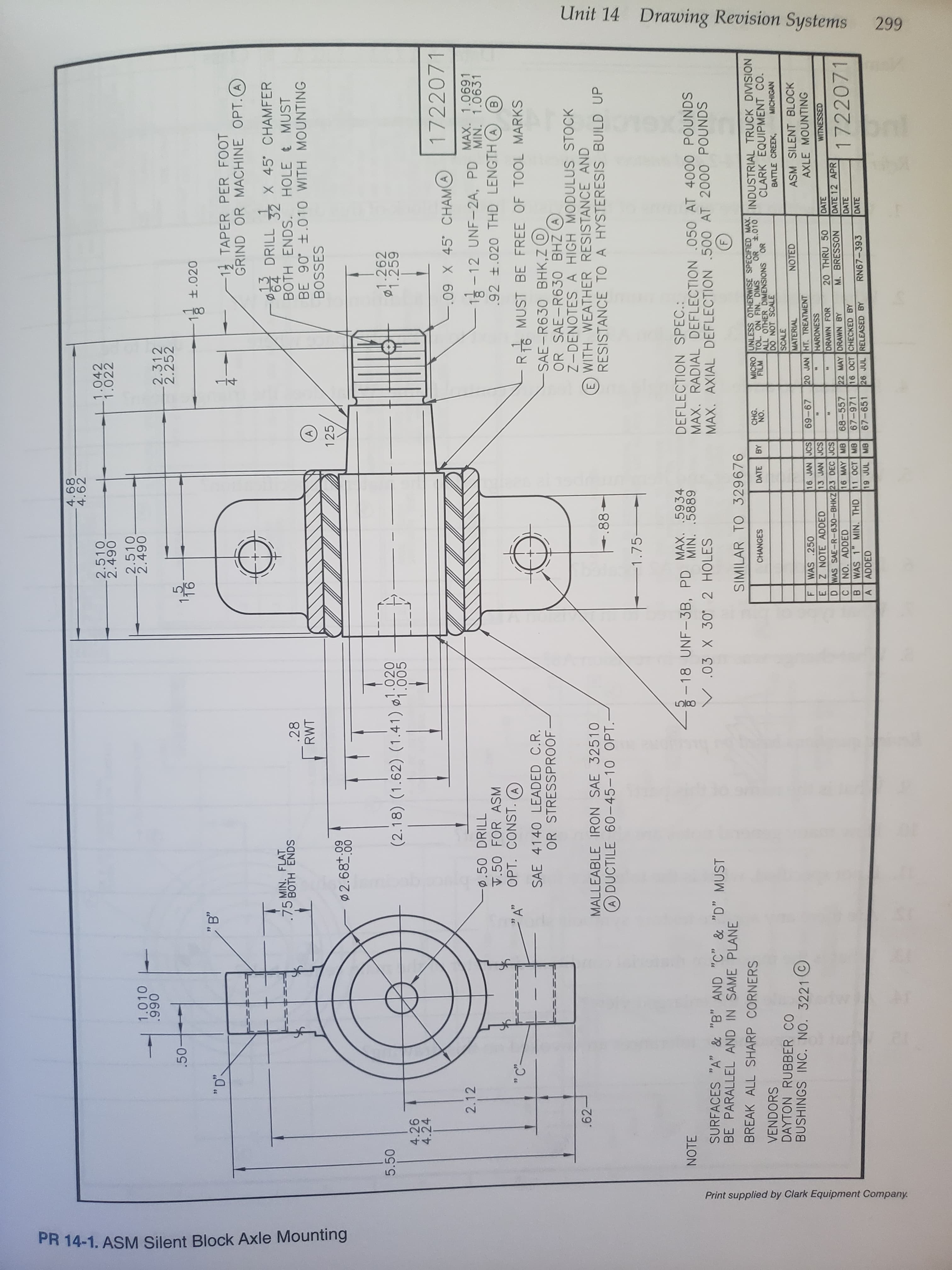

Date Name Industry Print Exercise 14-1 Refer to the print PR 14-1 and answer the questions below. 1. How many columns are featured in the revision history block of this drawing? 2. What is the current revision letter assigned to this part? 3. What revision specified the surface texture of the tapered portion? 4. What are the initials of the person who implemented or approved ECO 68-557? 5. Which revision specified the vendor part number of the bushing? 6. Revision F changed the maximum axial deflection to .500 at 2000 pounds. What had it been? 7. Instead of revision D, E, and F being three letters, what other method of marking could have been implemented for these three changes? Review questions based on previous units: 8. What is the thread form specified for the internal threaded holes? 9. What method was used to show external threads on this part? 10. Is this a drawing of multiple parts assembled? 11. Does this drawing feature any cutting-plane lines? 12. What is the radius of the undercut indicated by a local note? 13. What is the maximum material condition diameter of the largest cylindrical feature of this part? 14. This drawing has an italic "f" symbol on some surfaces in the left side view. What are these symbols? 15. What does the 125 near the check mark at revision A on the tapered surface mean? Inc. Unit 14 Drawing Revision Systems 299 14 Print supplied by Clark Equipment Company PR 14-1. ASM Silent Block Axle Mounting 4.68 4.62 2.510. 2.490 2.510 2.490 1.042 1.022 1.010 2.312 2.252 0 -1 t.020 " B" -12 TAPER PER FOOT GRIND OR MACHINE OPT.A MIN. FLAT .75 BOTH ENDS DDRILL X 45 CHAMFER 32 HOLE tMUST .28 RWT BOTH ENDS. BE 90 t.010 WITH MOUNTING BOSSES A 125 2.68+.09 000 5.50 (2.18) (1.62) (1.41) 1.005 1.262 1.259 4.26 4.24 1722071 .09 X 45 CHAMA 2.12 -0.50 DRILL V.50 FOR ASM OPT. CONST. 1-12 UNF-2A, PD .92 .020 THD LENGTH (A MAX. 1.0691 MIN. 1.0631 "A" A - R MUST BE FREE OF TOOL MARKS -SAE-R630 BHK,Z D OR SAE-R630 BHZ A Z-DENOTESA HIGH MODULUS STOCK E WITH WEATHER RESISTANCE AND RESISTANCE TO A HYSTERESIS BUILD UP SAE 4140 LEADED C.R. OR STRESSPROOF .62 MALLEABLE IRON SAE 32510 A DUCTILE 60-45-10 OPT. +.88 -1.75- 18 UNF-3B, PD V.03 X 30 2 HOLES MAX. .5934 MIN. .5889 NOTE SURFACES "A" & "B" AND "C" & "D" MUST BE PARALLEL AND IN SAME PLANE DEFLECTION SPEC.: MAX. RADIAL DEFLECTION .050 AT 4000 POUNDS MAX. AXIAL DEFLECTION .500 AT 2000 POUNDS BREAK ALL SHARP CORNERS SIMILAR TO 329676 CHG. NO. MICRO UNLESS OTHERWISE SPECIFIED MAX. FILM OR 010 INDUSTRIAL TRUCK DIVISION CLARK EQUIPMENT CO. CHANGES DATE BY VENDORS DAYTON RUBBER CO BUSHINGS INC. NO. 3221 C TOL. ON FIN. DIMS ALL OTHER DIMENSIONS DO NOT SCALE SCALE MATERIAL BATTLE CREEK, MICHIGAN NOTED ASM SILENT BLOCK 20 JAN HT. TREATMENT WAS .250 Z NOTE ADDED D WAS SAE-R-630-BHKZ 23 DEC JCS CNO. ADDED WAS 1 MIN. THD A ADDED 16 JAN JCS AXLE MOUNTING 13 JAN JCS HARDNESS 20 THRU 50 M. BRESSON DATE DATE 12 APR DATE DATE DRAWN FOR 68-557 67-971 67-651 22 MAY DRAWN BY 16 OCT CHECKED BY 26 JUL RELEASED BY 16 MAY MB 1722071 11 OCT MB RN67-393

Date Name Industry Print Exercise 14-1 Refer to the print PR 14-1 and answer the questions below. 1. How many columns are featured in the revision history block of this drawing? 2. What is the current revision letter assigned to this part? 3. What revision specified the surface texture of the tapered portion? 4. What are the initials of the person who implemented or approved ECO 68-557? 5. Which revision specified the vendor part number of the bushing? 6. Revision F changed the maximum axial deflection to .500 at 2000 pounds. What had it been? 7. Instead of revision D, E, and F being three letters, what other method of marking could have been implemented for these three changes? Review questions based on previous units: 8. What is the thread form specified for the internal threaded holes? 9. What method was used to show external threads on this part? 10. Is this a drawing of multiple parts assembled? 11. Does this drawing feature any cutting-plane lines? 12. What is the radius of the undercut indicated by a local note? 13. What is the maximum material condition diameter of the largest cylindrical feature of this part? 14. This drawing has an italic "f" symbol on some surfaces in the left side view. What are these symbols? 15. What does the 125 near the check mark at revision A on the tapered surface mean? Inc. Unit 14 Drawing Revision Systems 299 14 Print supplied by Clark Equipment Company PR 14-1. ASM Silent Block Axle Mounting 4.68 4.62 2.510. 2.490 2.510 2.490 1.042 1.022 1.010 2.312 2.252 0 -1 t.020 " B" -12 TAPER PER FOOT GRIND OR MACHINE OPT.A MIN. FLAT .75 BOTH ENDS DDRILL X 45 CHAMFER 32 HOLE tMUST .28 RWT BOTH ENDS. BE 90 t.010 WITH MOUNTING BOSSES A 125 2.68+.09 000 5.50 (2.18) (1.62) (1.41) 1.005 1.262 1.259 4.26 4.24 1722071 .09 X 45 CHAMA 2.12 -0.50 DRILL V.50 FOR ASM OPT. CONST. 1-12 UNF-2A, PD .92 .020 THD LENGTH (A MAX. 1.0691 MIN. 1.0631 "A" A - R MUST BE FREE OF TOOL MARKS -SAE-R630 BHK,Z D OR SAE-R630 BHZ A Z-DENOTESA HIGH MODULUS STOCK E WITH WEATHER RESISTANCE AND RESISTANCE TO A HYSTERESIS BUILD UP SAE 4140 LEADED C.R. OR STRESSPROOF .62 MALLEABLE IRON SAE 32510 A DUCTILE 60-45-10 OPT. +.88 -1.75- 18 UNF-3B, PD V.03 X 30 2 HOLES MAX. .5934 MIN. .5889 NOTE SURFACES "A" & "B" AND "C" & "D" MUST BE PARALLEL AND IN SAME PLANE DEFLECTION SPEC.: MAX. RADIAL DEFLECTION .050 AT 4000 POUNDS MAX. AXIAL DEFLECTION .500 AT 2000 POUNDS BREAK ALL SHARP CORNERS SIMILAR TO 329676 CHG. NO. MICRO UNLESS OTHERWISE SPECIFIED MAX. FILM OR 010 INDUSTRIAL TRUCK DIVISION CLARK EQUIPMENT CO. CHANGES DATE BY VENDORS DAYTON RUBBER CO BUSHINGS INC. NO. 3221 C TOL. ON FIN. DIMS ALL OTHER DIMENSIONS DO NOT SCALE SCALE MATERIAL BATTLE CREEK, MICHIGAN NOTED ASM SILENT BLOCK 20 JAN HT. TREATMENT WAS .250 Z NOTE ADDED D WAS SAE-R-630-BHKZ 23 DEC JCS CNO. ADDED WAS 1 MIN. THD A ADDED 16 JAN JCS AXLE MOUNTING 13 JAN JCS HARDNESS 20 THRU 50 M. BRESSON DATE DATE 12 APR DATE DATE DRAWN FOR 68-557 67-971 67-651 22 MAY DRAWN BY 16 OCT CHECKED BY 26 JUL RELEASED BY 16 MAY MB 1722071 11 OCT MB RN67-393

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answers to questions 4, 5, and 6 pertaining to the print provided.

Transcribed Image Text:Date

Name

Industry Print Exercise 14-1

Refer to the print PR 14-1 and answer the questions below.

1. How many columns are featured in the revision history block of this drawing?

2. What is the current revision letter assigned to this part?

3. What revision specified the surface texture of the tapered portion?

4. What are the initials of the person who implemented or approved ECO 68-557?

5. Which revision specified the vendor part number of the bushing?

6. Revision F changed the maximum axial deflection to .500 at 2000 pounds. What had it been?

7. Instead of revision D, E, and F being three letters, what other method of marking could have been

implemented for these three changes?

Review questions based on previous units:

8. What is the thread form specified for the internal threaded holes?

9. What method was used to show external threads on this part?

10. Is this a drawing of multiple parts assembled?

11. Does this drawing feature any cutting-plane lines?

12. What is the radius of the undercut indicated by a local note?

13. What is the maximum material condition diameter of the largest cylindrical feature of this part?

14. This drawing has an italic "f" symbol on some surfaces in the left side view. What are these symbols?

15. What does the 125 near the check mark at revision A on the tapered surface mean?

Inc.

Transcribed Image Text:Unit 14

Drawing Revision Systems

299

14

Print supplied by Clark Equipment Company

PR 14-1. ASM Silent Block Axle Mounting

4.68

4.62

2.510.

2.490

2.510

2.490

1.042

1.022

1.010

2.312

2.252

0

-1 t.020

" B"

-12 TAPER PER FOOT

GRIND OR MACHINE OPT.A

MIN. FLAT

.75 BOTH ENDS

DDRILL X 45 CHAMFER

32

HOLE tMUST

.28

RWT

BOTH ENDS.

BE 90 t.010 WITH MOUNTING

BOSSES

A

125

2.68+.09

000

5.50

(2.18) (1.62) (1.41) 1.005

1.262

1.259

4.26

4.24

1722071

.09 X 45 CHAMA

2.12

-0.50 DRILL

V.50 FOR ASM

OPT. CONST.

1-12 UNF-2A, PD

.92 .020 THD LENGTH (A

MAX. 1.0691

MIN. 1.0631

"A"

A

- R MUST BE FREE OF TOOL MARKS

-SAE-R630 BHK,Z D

OR SAE-R630 BHZ A

Z-DENOTESA HIGH MODULUS STOCK

E WITH WEATHER RESISTANCE AND

RESISTANCE TO A HYSTERESIS BUILD UP

SAE 4140 LEADED C.R.

OR STRESSPROOF

.62

MALLEABLE IRON SAE 32510

A DUCTILE 60-45-10 OPT.

+.88

-1.75-

18 UNF-3B, PD

V.03 X 30 2 HOLES

MAX. .5934

MIN. .5889

NOTE

SURFACES "A" & "B" AND "C" & "D" MUST

BE PARALLEL AND IN SAME PLANE

DEFLECTION SPEC.:

MAX. RADIAL DEFLECTION .050 AT 4000 POUNDS

MAX. AXIAL DEFLECTION .500 AT 2000 POUNDS

BREAK ALL SHARP CORNERS

SIMILAR TO 329676

CHG.

NO.

MICRO UNLESS OTHERWISE SPECIFIED MAX.

FILM

OR 010 INDUSTRIAL TRUCK DIVISION

CLARK EQUIPMENT CO.

CHANGES

DATE

BY

VENDORS

DAYTON RUBBER CO

BUSHINGS INC. NO. 3221 C

TOL. ON FIN. DIMS

ALL OTHER DIMENSIONS

DO NOT SCALE

SCALE

MATERIAL

BATTLE CREEK,

MICHIGAN

NOTED

ASM SILENT BLOCK

20 JAN HT. TREATMENT

WAS .250

Z NOTE ADDED

D WAS SAE-R-630-BHKZ 23 DEC JCS

CNO. ADDED

WAS 1 MIN. THD

A ADDED

16 JAN JCS

AXLE MOUNTING

13 JAN JCS

HARDNESS

20 THRU 50

M. BRESSON

DATE

DATE 12 APR

DATE

DATE

DRAWN FOR

68-557

67-971

67-651

22 MAY DRAWN BY

16 OCT CHECKED BY

26 JUL RELEASED BY

16 MAY MB

1722071

11 OCT MB

RN67-393

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY