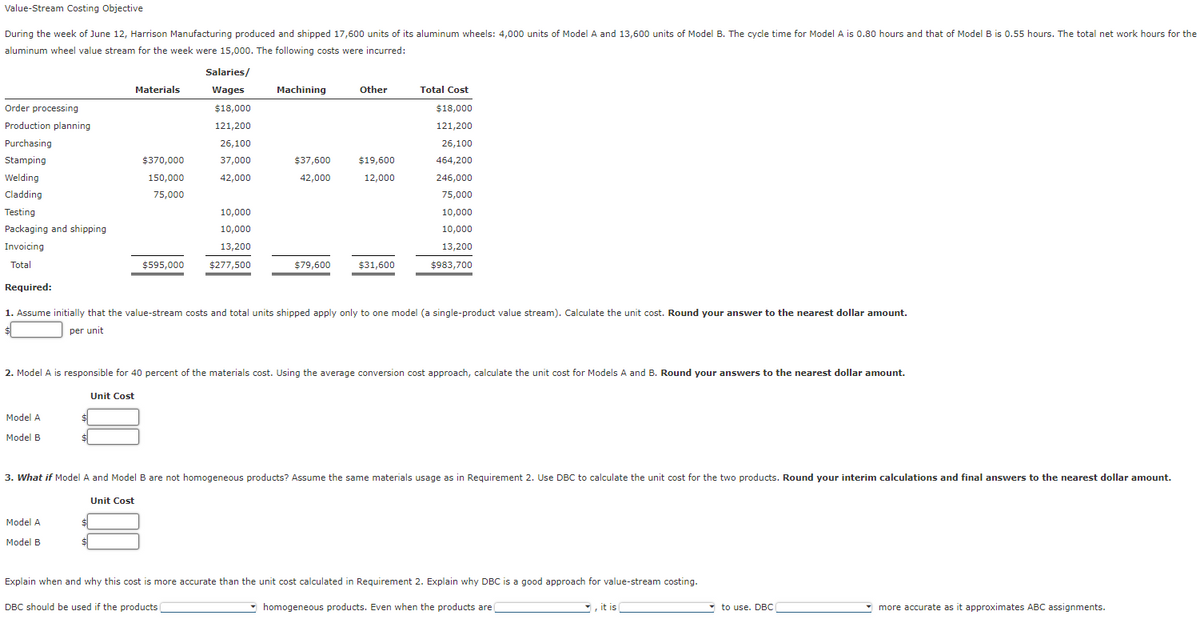

During the week of June 12, Harrison Manufacturing produced and shipped 17,600 units of its aluminum wheels: 4,000 units of Model A and 13,600 units of Model B. The cycle time for Model A is 0.80 hours and that of Model B is 0.55 hours. The total net work hours for the aluminum wheel value stream for the week were 15,000. The following costs were incurred: Salaries/ Materials Wages Machining $18,000 121,200 26,100 38 $370,000 37,000 $37,600 150,000 42,000 42,000 75,000 10,000 10,000 13,200 $277,500 Order processing Production planning Purchasing Stamping Welding Cladding Testing Packaging and shipping Invoicing Total Required: 1. Assume initially that the value-stream costs and total units shipped apply only to one model (a single-product value stream). Calculate the unit cost. Round your answer to the nearest dollar amount. per unit Model A Model B Other Total Cost $18,000 121,200 $595,000 Model A Model B $19,600 12,000 $79,600 $31,600 2. Model A is responsible for 40 percent of the materials cost. Using the average conversion cost approach, calculate the unit cost for Models A and B. Round your answers to the nearest dollar amount. Unit Cost 26,100 464,200 246,000 75,000 10,000 10,000 13,200 $983,700 3. What if Model A and Model B are not homogeneous products? Assume the same materials usage as in Requirement 2. Use DBC to calculate the unit cost for the two products. Round your interim calculations and final answers to the nearest dollar amount. Unit Cost

During the week of June 12, Harrison Manufacturing produced and shipped 17,600 units of its aluminum wheels: 4,000 units of Model A and 13,600 units of Model B. The cycle time for Model A is 0.80 hours and that of Model B is 0.55 hours. The total net work hours for the aluminum wheel value stream for the week were 15,000. The following costs were incurred: Salaries/ Materials Wages Machining $18,000 121,200 26,100 38 $370,000 37,000 $37,600 150,000 42,000 42,000 75,000 10,000 10,000 13,200 $277,500 Order processing Production planning Purchasing Stamping Welding Cladding Testing Packaging and shipping Invoicing Total Required: 1. Assume initially that the value-stream costs and total units shipped apply only to one model (a single-product value stream). Calculate the unit cost. Round your answer to the nearest dollar amount. per unit Model A Model B Other Total Cost $18,000 121,200 $595,000 Model A Model B $19,600 12,000 $79,600 $31,600 2. Model A is responsible for 40 percent of the materials cost. Using the average conversion cost approach, calculate the unit cost for Models A and B. Round your answers to the nearest dollar amount. Unit Cost 26,100 464,200 246,000 75,000 10,000 10,000 13,200 $983,700 3. What if Model A and Model B are not homogeneous products? Assume the same materials usage as in Requirement 2. Use DBC to calculate the unit cost for the two products. Round your interim calculations and final answers to the nearest dollar amount. Unit Cost

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter15: Lean Accounting And Productivity Measurement

Section: Chapter Questions

Problem 2CE: During the week of June 12, Harrison Manufacturing produced and shipped 15,000 units of its aluminum...

Related questions

Question

Transcribed Image Text:Value-Stream Costing Objective

During the week of June 12, Harrison Manufacturing produced and shipped 17,600 units of its aluminum wheels: 4,000 units of Model A and 13,600 units of Model B. The cycle time for Model A is 0.80 hours and that of Model B is 0.55 hours. The total net work hours for the

aluminum wheel value stream for the week were 15,000. The following costs were incurred:

Salaries/

Materials

Wages

Machining

$18,000

121,200

26,100

GF

$370,000

37,000

$37,600

150,000

42,000

42,000

75,000

10,000

10,000

13,200

$277,500

$79,600

Order processing

Production planning

Purchasing

Stamping

Welding

Cladding

Testing

Packaging and shipping

Invoicing

Total

$595,000

Model A

Model B

Other

Model A

Model B

$19,600

12,000

$31,600

Required:

1. Assume initially that the value-stream costs and total units shipped apply only to one model (a single-product value stream). Calculate the unit cost. Round your answer to the nearest dollar amount.

$

per unit

DBC should be used if the products

Total Cost

2. Model A is responsible for 40 percent of the materials cost. Using the average conversion cost approach, calculate the unit cost for Models A and B. Round your answers to the nearest dollar amount.

Unit Cost

$18,000

121,200

26,100

464,200

246,000

75,000

10,000

10,000

13,200

$983,700

3. What if Model A and Model B are not homogeneous products? Assume the same materials usage as in Requirement 2. Use DBC to calculate the unit cost for the two products. Round your interim calculations and final answers to the nearest dollar amount.

Unit Cost

Explain when and why this cost is more accurate than the unit cost calculated in Requirement 2. Explain why DBC is a good approach for value-stream costing.

homogeneous products. Even when the products are

, it is

to use. DBC

more accurate as it approximates ABC assignments.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College