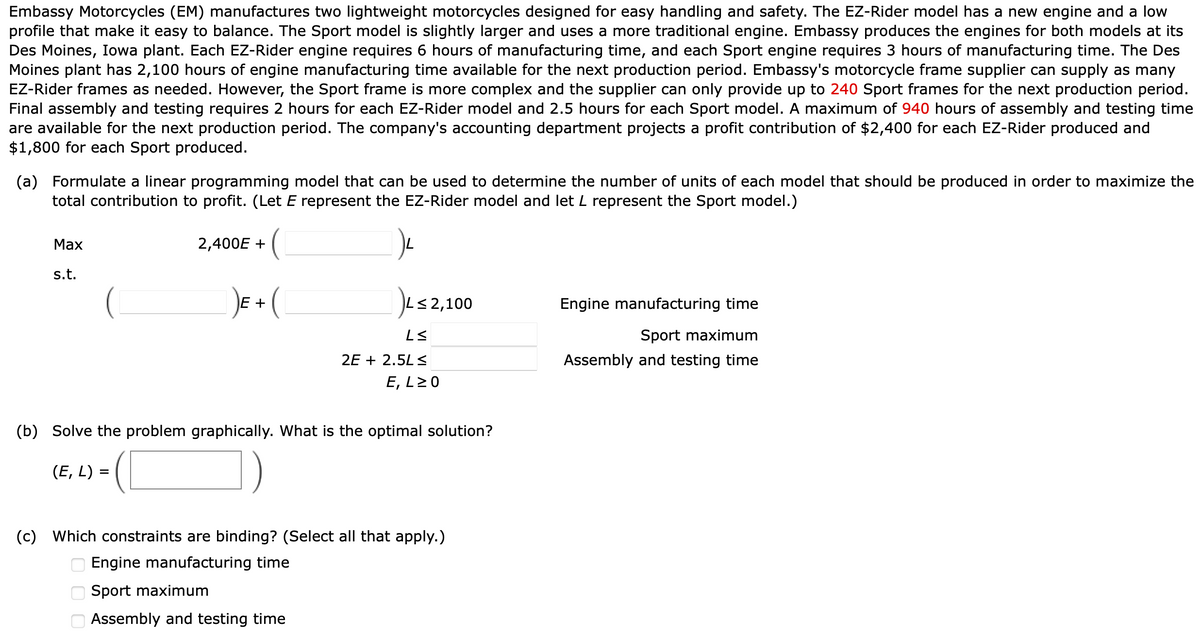

Embassy Motorcycles (EM) manufactures two lightweight motorcycles designed for easy handling and safety. The EZ-Rider model has a new engine and a low profile that make it easy to balance. The Sport model is slightly larger and uses a more traditional engine. Embassy produces the engines for both models at its Des Moines, Iowa plant. Each EZ-Rider engine requires 6 hours of manufacturing time, and each Sport engine requires 3 hours of manufacturing time. The Des Moines plant has 2,100 hours of engine manufacturing time available for the next production period. Embassy's motorcycle frame supplier can supply as many EZ-Rider frames as needed. However, the Sport frame is more complex and the supplier can only provide up to 240 Sport frames for the next production period. Final assembly and testing requires 2 hours for each EZ-Rider model and 2.5 hours for each Sport model. A maximum of 940 hours of assembly and testing time are available for the next production period. The company's accounting department projects a profit contribution of $2,400 for each EZ-Rider produced and $1,800 for each Sport produced. (a) Formulate a linear programming model that can be used to determine the number of units of each model that should be produced in order to maximize the total contribution to profit. (Let E represent the EZ-Rider model and let L represent the Sport model.) Max s.t. 2,400E + )E+ ( L≤ 2,100 LS 2E + 2.5L< E, L≥O (b) Solve the problem graphically. What is the optimal solution? (E, L) = (c) Which constraints are binding? (Select all that apply.) Engine manufacturing time Sport maximum Assembly and testing time Engine manufacturing time Sport maximum Assembly and testing time

Embassy Motorcycles (EM) manufactures two lightweight motorcycles designed for easy handling and safety. The EZ-Rider model has a new engine and a low profile that make it easy to balance. The Sport model is slightly larger and uses a more traditional engine. Embassy produces the engines for both models at its Des Moines, Iowa plant. Each EZ-Rider engine requires 6 hours of manufacturing time, and each Sport engine requires 3 hours of manufacturing time. The Des Moines plant has 2,100 hours of engine manufacturing time available for the next production period. Embassy's motorcycle frame supplier can supply as many EZ-Rider frames as needed. However, the Sport frame is more complex and the supplier can only provide up to 240 Sport frames for the next production period. Final assembly and testing requires 2 hours for each EZ-Rider model and 2.5 hours for each Sport model. A maximum of 940 hours of assembly and testing time are available for the next production period. The company's accounting department projects a profit contribution of $2,400 for each EZ-Rider produced and $1,800 for each Sport produced. (a) Formulate a linear programming model that can be used to determine the number of units of each model that should be produced in order to maximize the total contribution to profit. (Let E represent the EZ-Rider model and let L represent the Sport model.) Max s.t. 2,400E + )E+ ( L≤ 2,100 LS 2E + 2.5L< E, L≥O (b) Solve the problem graphically. What is the optimal solution? (E, L) = (c) Which constraints are binding? (Select all that apply.) Engine manufacturing time Sport maximum Assembly and testing time Engine manufacturing time Sport maximum Assembly and testing time

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter5: Network Models

Section: Chapter Questions

Problem 66P

Related questions

Question

100%

Transcribed Image Text:Embassy Motorcycles (EM) manufactures two lightweight motorcycles designed for easy handling and safety. The EZ-Rider model has a new engine and a low

profile that make it easy to balance. The Sport model is slightly larger and uses a more traditional engine. Embassy produces the engines for both models at its

Des Moines, Iowa plant. Each EZ-Rider engine requires 6 hours of manufacturing time, and each Sport engine requires 3 hours of manufacturing time. The Des

Moines plant has 2,100 hours of engine manufacturing time available for the next production period. Embassy's motorcycle frame supplier can supply as many

EZ-Rider frames as needed. However, the Sport frame is more complex and the supplier can only provide up to 240 Sport frames for the next production period.

Final assembly and testing requires 2 hours for each EZ-Rider model and 2.5 hours for each Sport model. A maximum of 940 hours of assembly and testing time

are available for the next production period. The company's accounting department projects a profit contribution of $2,400 for each EZ-Rider produced and

$1,800 for each Sport produced.

(a) Formulate a linear programming model that can be used to determine the number of units of each model that should be produced in order to maximize the

total contribution to profit. (Let E represent the EZ-Rider model and let L represent the Sport model.)

Max

s.t.

(

)E + (

=

0 0 0

2,400E +

1)LS2,

LS

≤ 2,100

(b) Solve the problem graphically. What is the optimal solution?

(E, L) =

Engine

Sport maximum

Assembly and testing time

2E + 2.5L ≤

E, L≥0

(c) Which constraints are binding? (Select all that apply.)

manufacturing time

Engine manufacturing time

Sport maximum

Assembly and testing time

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 1 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,